2025 Top Filling Machine Innovations Enhancing Efficiency and Precision in Manufacturing

In the ever-evolving landscape of manufacturing, the year 2025 is set to witness groundbreaking innovations in filling machine technology, driving improvements in both efficiency and precision. Industry expert Dr. Emma Thornton, a leading figure in automation and production systems, states, "The future of manufacturing is not just about speed; it's about integrating cutting-edge technologies to create filling machines that are smarter, more adaptable, and capable of delivering higher-quality products." This emphasis on smart manufacturing highlights the transformative impact of digital innovations that tech-savvy companies are leveraging to enhance their operations.

As the demand for high-quality, precise filling solutions escalates, manufacturers are recognizing the importance of investing in advanced filling machine systems that incorporate the latest technology. From artificial intelligence and machine learning algorithms to IoT connectivity and automated quality control, these innovations are reshaping how products are filled and packaged. By embracing these changes, businesses not only meet consumer expectations but also optimize their production lines for maximum output and reduced waste.

As we delve into the top filling machine innovations anticipated for 2025, it is essential to explore how these developments can elevate manufacturing practices. Through enhanced accuracy, reduced downtime, and increased flexibility, the next generation of filling machines promises to revolutionize industries ranging from food and beverage to pharmaceuticals, ensuring a more efficient manufacturing future.

Emerging Trends in Filling Machine Technology for 2025

As we look ahead to 2025, the filling machine technology industry is poised for significant advancements, particularly in the dual chamber syringe (DCS) sector. The global market for DCS filling machines is projected to expand from $365.2 million in 2025 to an impressive $643.0 million by 2032. This surge signifies a growing demand for precision and efficiency in pharmaceutical manufacturing, driven by innovations that enhance both the speed and accuracy of filling processes.

Furthermore, the broader trends within the packaging industry highlight a transition towards more automated and versatile filling solutions. The pharmaceutical capsule filling machines market is also on the rise, expected to reach USD 3.2 billion by 2035 with a compound annual growth rate (CAGR) of 5.9% from 2025. These figures reflect an overall shift in manufacturing practices, where the integration of cutting-edge technology is essential not just for meeting capacity demands, but also for adhering to increasingly stringent regulatory standards in the pharmaceutical sector. As 2025 approaches, manufacturers must stay attuned to these trends to capitalize on emerging opportunities and enhance operational efficiencies.

2025 Top Filling Machine Innovations Enhancing Efficiency and Precision in Manufacturing

This chart illustrates the projected advancements in filling machine technology for 2025, focusing on key innovations expected to enhance efficiency and precision in the manufacturing process.

Key Features of Advanced Filling Machines Enhancing Manufacturing Processes

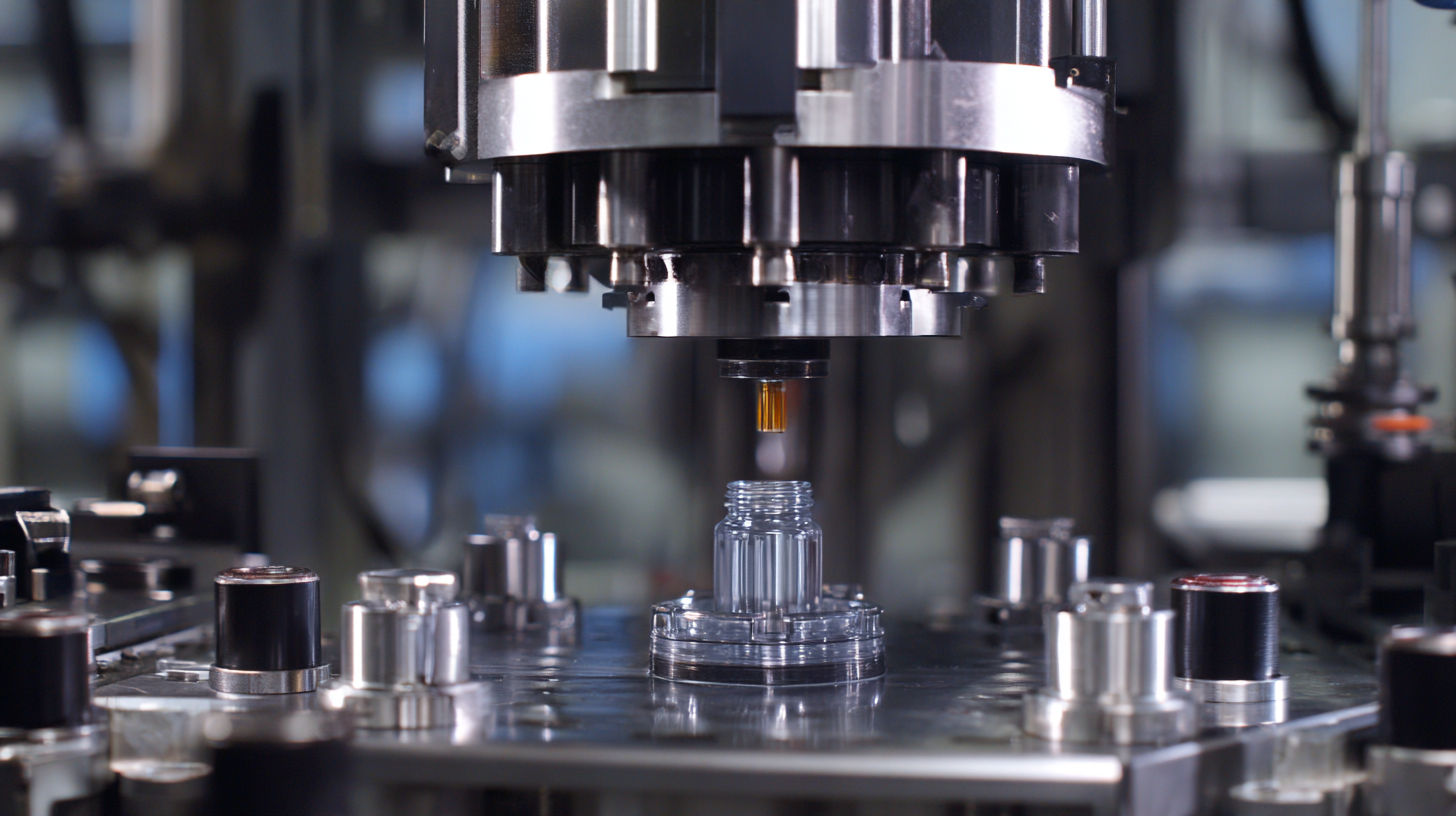

The landscape of manufacturing is rapidly evolving, particularly with the introduction of

advanced filling machines that incorporate cutting-edge technologies.

These innovations are geared towards enhancing precision and efficiency, critical

factors in industries like pharmaceuticals and food and beverage. Recent reports indicate that

the global market for robotic vial washing and filling machines is projected to experience significant growth,

driven by the increasing demand for injectable drugs and the necessity for automation in manufacturing processes.

With the advent of smart machinery, manufacturers can optimize production lines, ensuring minimal waste and

maximum throughput.

In terms of key features, advanced filling machines are now equipped with sophisticated sensors and Artificial Intelligence (AI) algorithms that allow for real-time monitoring and data collection. This ensures that any discrepancies in the filling process are quickly identified, significantly reducing the risk of human error. Additionally, the incorporation of deep learning approaches in machinery health management enhances predictive maintenance, enabling manufacturers to anticipate and rectify faults before they disrupt operations. As the manufacturing sector looks towards 2026 and beyond, the integration of these technologies will be crucial in maintaining a competitive advantage, ensuring adaptability in an ever-changing market landscape.

Impact of Automation on Filling Machine Efficiency and Precision

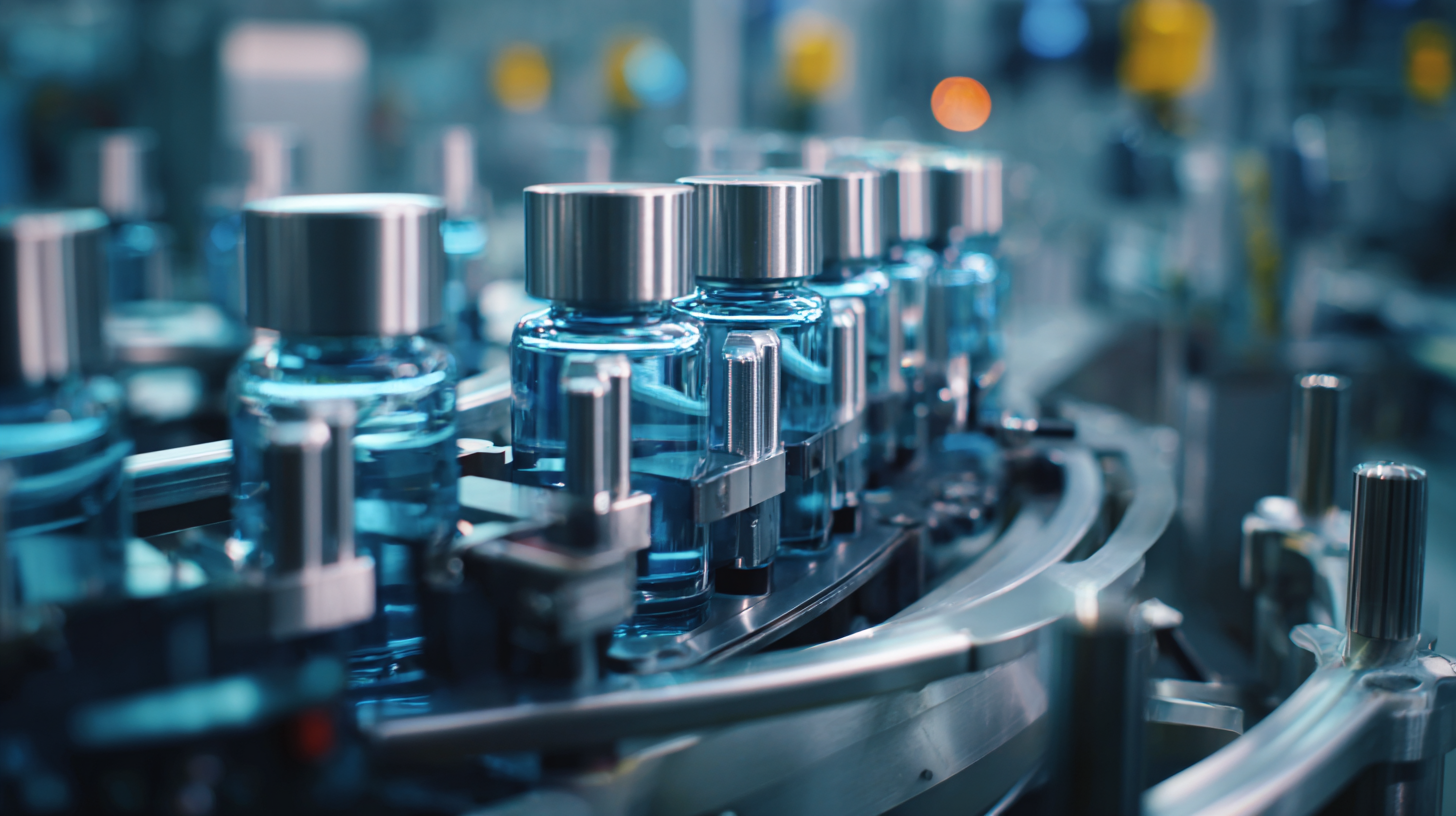

The liquid filling machine market is experiencing significant growth, driven by advancements in automation that enhance efficiency and precision in manufacturing processes. Automation has revolutionized the way filling machines operate, allowing for faster production speeds and greater accuracy in filling volumes. As manufacturers adopt automated solutions, the sector is witnessing a marked increase in the deployment of both fully automatic and semi-automatic machines tailored to meet diverse operational needs.

Segmenting the market by product type reveals a robust demand for filling machines across various materials such as glass, plastic, TETRA packaging, and cartons. Each packaging type necessitates specific filling technologies, with vacuum filling, volume filling, and weighing methods being predominant. The distinct requirements of different industries further propel innovation, encouraging manufacturers to develop tailored solutions that cater to precise filling needs. As the landscape of liquid filling continues to evolve, the focus on integrating cutting-edge technologies remains pivotal in achieving higher operational efficiencies and enhancing product quality.

2025 Top Filling Machine Innovations Enhancing Efficiency and Precision in Manufacturing

| Innovation | Efficiency Improvement (%) | Precision Rate (%) | Automation Impact Level | Notes |

|---|---|---|---|---|

| Smart Sensor Integration | 25% | 98% | High | Enhances real-time monitoring |

| AI-Powered Quality Control | 30% | 95% | Medium | Reduces defects in products |

| Robotic Automation | 40% | 97% | Very High | Increases speed and throughput |

| Blockchain for Supply Chain Transparency | 15% | 99% | Low | Improves traceability |

| Customizable Modular Designs | 20% | 96% | Medium | Adaptable to various products |

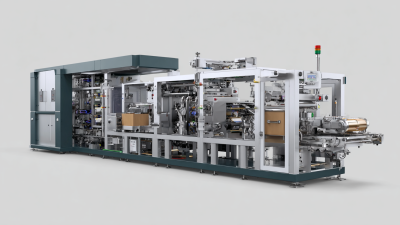

Innovative Materials and Designs in 2025 Filling Machine Development

The landscape of filling machine technology is rapidly evolving, particularly in 2025, where innovative materials and designs are at the forefront of enhancing both efficiency and precision in manufacturing. Advances in materials such as lightweight composites and durable polymers are revolutionizing the manufacturing process by reducing wear and tear on machine components, thereby increasing longevity and performance. Reports indicate that around 45% of manufacturers are investing in these new materials to optimize their production lines and minimize downtime.

One of the key trends in the development of filling machines is the integration of smart technologies. Devices equipped with IoT capabilities allow for real-time monitoring and data analytics, enabling manufacturers to adjust their processes dynamically. A recent study found that companies employing smart filling systems saw a 30% increase in output and a significant reduction in operational waste. This innovation not only improves efficiency but also ensures higher precision in product filling, catering to increasingly stringent regulatory standards.

Tips: When considering upgrades to your filling machines, prioritize the adoption of materials and designs that support sustainability. Moreover, investing in IoT integrations can significantly boost productivity while providing valuable data insights for continuous improvement. Engaging with suppliers who specialize in innovative filling technologies can also enhance your competitive edge in a demanding market.

Sustainability Considerations in Modern Filling Machine Innovations

In 2025, the evolution of filling machine technology is significantly influenced by the growing emphasis on sustainability. Modern manufacturing processes are integrating eco-friendly materials and energy-efficient designs that reduce waste and lower carbon footprints. For instance, innovative filling machines now utilize biodegradable components and recyclable packaging options, ensuring that the production cycle aligns with environmental conservation goals. This shift not only enhances operational efficiency but also caters to a market increasingly driven by sustainability-conscious consumers.

Additionally, advancements in automation and smart technology play a pivotal role in bolstering the sustainability of filling machines. These innovations allow for precise filling processes that minimize product overfill and reduce material waste. With real-time monitoring systems, manufacturers can optimize their operations, making adjustments to conserve energy and resources. This integrative approach illustrates how the intersection of technology and environmental responsibility is reshaping the manufacturing landscape, positioning companies to meet both operational goals and ecological demands.

Related Posts

-

Revolutionizing Supply Chains: The Future of Industrial Packaging Equipment Explained

-

Mastering Efficiency: How VFFS Machines Revolutionize Packaging Processes for Modern Businesses

-

10 Best Custom Packaging Machines for Your Business Needs

-

Revolutionizing Packaging: How Automatic Bagging Machines Enhance Efficiency and Precision in Industries

-

Top 10 Custom Packaging Machines to Boost Your Business Efficiency in 2023

-

The Essential Guide to Choosing the Best Material Handling Carts for Your Business Needs