Revolutionizing Efficiency: How Automated Packaging Machines Transform Your Production Line

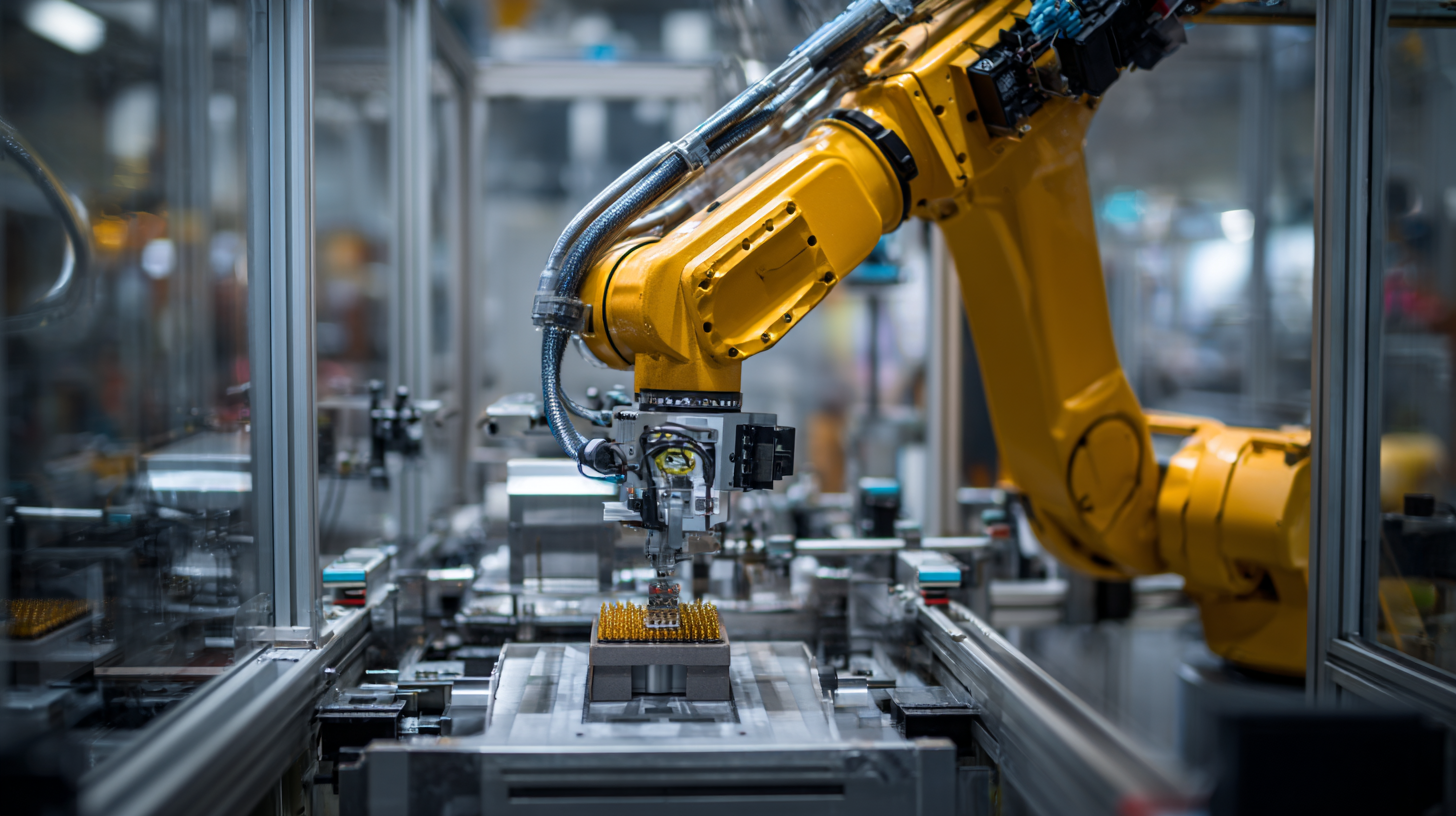

In today's fast-paced manufacturing environment, the need for efficiency and precision has never been more critical. Enter the automated packaging machine—a revolutionary solution that is transforming production lines across various industries. These sophisticated machines streamline the packaging process, minimizing human error and maximizing throughput. By integrating automation into packaging, businesses can reduce labor costs, improve consistency, and enhance overall productivity.

The versatility of an automated packaging machine allows it to adapt to different product types and packaging formats, thus catering to a wide range of market demands. As companies strive to remain competitive, investing in automated packaging technologies is not just a trend but a necessity for achieving operational excellence and ensuring a rapid response to changing consumer needs. This article delves into the intricacies of automated packaging machines and their significant impact on production line efficiency.

The Role of Automated Packaging Machines in Modern Production Lines

Automated packaging machines play a pivotal role in modern production lines, significantly enhancing efficiency and reliability. These machines streamline the packaging process by minimizing human intervention, which not only accelerates production speed but also reduces the likelihood of errors. With precision engineering, automated systems can handle various packaging materials and styles, adapting to the ever-changing demands of the market. This adaptability ensures that businesses can maintain competitiveness by swiftly responding to new product launches and consumer trends.

Moreover, the integration of automated packaging machines leads to improved workplace safety and reduced labor costs. By automating repetitive tasks, workers can focus on more complex and value-added activities, fostering a more skilled and engaged workforce. Additionally, the consistent output of these machines contributes to enhanced product quality, as they maintain strict adherence to packaging standards. As a result, companies can achieve greater operational efficiency, ultimately driving profitability in an increasingly competitive landscape.

Revolutionizing Efficiency: How Automated Packaging Machines Transform Your Production Line

| Dimension | Value | Impact |

|---|---|---|

| Machine Speed (items/min) | 120 | Increases throughput significantly |

| Error Rate (%) | 0.5 | Minimizes product waste |

| Setup Time (minutes) | 15 | Reduces downtime |

| Labor Cost Savings (%) | 30 | Improves overall efficiency |

| Space Utilization (%) | 85 | Optimizes production area |

Key Benefits of Implementing Automated Packaging Solutions

The global automated packaging market is witnessing a transformative shift as industries increasingly adopt advanced packaging solutions driven by automation and artificial intelligence. By 2025, the market size for food automation is expected to reach approximately $8.98 billion, with a projected compound annual growth rate (CAGR) of 3.9%, growing further to an estimated $12.2 billion by 2033. This growth reflects the urgent need for enhanced efficiency and productivity on production lines, as businesses seek to streamline their operations and meet consumer demands for faster delivery and better packaging quality.

In addition to the food sector, the sustainable packaging equipment market is set to surpass $157.6 billion by 2024, driven by the increasing importance of sustainability in packaging solutions. The projected CAGR of over 7.3% from 2025 to 2034 highlights how companies are prioritizing eco-friendly practices while leveraging automation technologies. Moreover, the broader packaging machinery market is on an upward trajectory, with a projected growth from $42.13 billion in 2019 to approximately $70.23 billion by 2032, underscoring the critical role that automated packaging innovations play across various industries, including pharmaceuticals and consumer goods. The integration of machine learning and AI techniques further enhances testing systems within the semiconductor landscape, facilitating a more robust and efficient approach to production line management.

Types of Automated Packaging Machines Available for Various Industries

Automated packaging machines have become pivotal in transforming production lines across various industries. These machines come in various types — from manual and semi-automatic to fully automatic, each designed to cater to specific operational needs. For instance, manual machines are often employed in small-scale operations where budget constraints prioritize simplicity, while semi-automatic systems offer increased output for growing businesses. Fully automatic machines, on the other hand, dominate large production lines with their speed and precision, allowing manufacturers to meet high demand while ensuring consistent quality.

The impact of these machines extends beyond mere efficiency. They significantly enhance the sustainability of production processes by using materials more effectively and reducing waste. Furthermore, the integration of smart technology in automated packaging solutions enables real-time monitoring and data collection, fostering a more agile manufacturing environment. As industries adapt to the evolving market demands, the advancement of automated packaging technology underscores a crucial shift towards innovation and competitive edge in today's economy.

Revolutionizing Efficiency: Automated Packaging Machine Types and Their Usage

This chart illustrates the sales figures for various types of automated packaging machines, highlighting their importance in enhancing production line efficiency across different industries.

Impact of Automation on Labor Efficiency and Cost Reduction

Automation is fundamentally transforming production lines, delivering significant impacts on labor efficiency and cost reduction. By incorporating automated packaging machines, companies can achieve higher production rates and better utilization of materials, leading to improved productivity. A recent study highlighted that businesses embracing automation can experience a 30% increase in operational efficiency, minimizing human error, and enhancing consistency in the manufacturing process. Moreover, with labor costs continuing to be a major expense—consuming up to 30% of overall revenue—automation provides a viable solution, driving down costs and improving profit margins.

Automation is fundamentally transforming production lines, delivering significant impacts on labor efficiency and cost reduction. By incorporating automated packaging machines, companies can achieve higher production rates and better utilization of materials, leading to improved productivity. A recent study highlighted that businesses embracing automation can experience a 30% increase in operational efficiency, minimizing human error, and enhancing consistency in the manufacturing process. Moreover, with labor costs continuing to be a major expense—consuming up to 30% of overall revenue—automation provides a viable solution, driving down costs and improving profit margins.

Tips:

- Consider evaluating your current workflow to identify bottlenecks that automation could address.

- Invest in training your workforce to adapt to new technologies, ensuring a smoother transition and maximizing the benefits of automation.

As automation technologies advance, industries such as banking and healthcare are leveraging these systems to streamline operations, reduce processing times, and enhance service delivery. With generative AI expected to contribute trillions in economic value, the potential for automation in the production line cannot be overstated. By embracing these technologies, businesses not only enhance their efficiency but also position themselves for sustainable growth in a competitive landscape.

Future Trends in Automated Packaging Technology and Innovation

The automated packaging industry is undergoing a significant transformation, driven by advancements in technology and increasing consumer demands for efficiency and sustainability. According to recent market reports, the global advanced packaging equipment market is projected to reach approximately $9.81 billion by 2024, with expectations of soaring to around $26.71 billion by 2032. This rapid growth underscores the shift towards smart and sustainable solutions in packaging processes, highlighting innovation as a core trend in the sector.

Future trends indicate a strong focus on integrating artificial intelligence and automation into production lines to enhance efficiency. These technologies not only streamline operations but also facilitate better resource management, crucial in a world increasingly conscious of environmental impacts. As industries adapt to the changing landscape, innovations such as smart logistics and sustainable packaging materials are anticipated to play a pivotal role in shaping the future of automated packaging. Companies are gearing up for this evolution, making investments in cutting-edge technologies that promise to redefine production methodologies and meet the rising expectations of consumers for greener solutions.

Related Posts

-

Transform Your Workspace: The Ultimate Guide to Selecting the Perfect Material Handling Carts

-

Revolutionizing Packaging: How Automatic Bagging Machines Enhance Efficiency and Precision in Industries

-

Innovative Material Handling Carts for Efficient Workplace Organization and Productivity

-

The Essential Guide to Choosing the Best Material Handling Carts for Your Business Needs

-

Revolutionizing the Food Industry How Food Packaging Machines Enhance Freshness and Sustainability

-

Exploring the Future of Conveyor Systems in Automation and Smart Manufacturing