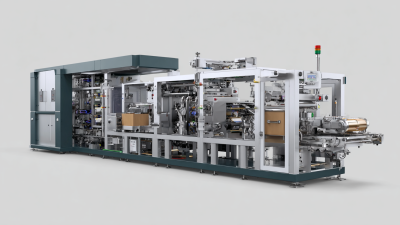

Top 5 Benefits of Using an Automated Packaging Machine for Your Business

As industries continue to evolve in response to market demands, the role of technology in enhancing operational efficiency has never been more critical. An automated packaging machine stands out as a revolutionary advancement in the packaging sector, significantly transforming the way businesses handle their products. According to John Miller, a leading expert in packaging technology, "The integration of automated packaging machines in production lines not only streamlines processes but also ensures consistent quality and reduces labor costs."

As industries continue to evolve in response to market demands, the role of technology in enhancing operational efficiency has never been more critical. An automated packaging machine stands out as a revolutionary advancement in the packaging sector, significantly transforming the way businesses handle their products. According to John Miller, a leading expert in packaging technology, "The integration of automated packaging machines in production lines not only streamlines processes but also ensures consistent quality and reduces labor costs."

With these machines, businesses can automate repetitive tasks, resulting in faster turnaround times and increased output. The shift towards automation is a strategic move embraced by various sectors, from food and beverage to pharmaceuticals, where precision and reliability are paramount. By exploring the top benefits of utilizing automated packaging machines, companies can better understand how this technology can enhance productivity, reduce waste, and ultimately drive profitability. As the demand for efficiency intensifies, investing in an automated packaging machine could very well be a defining factor for success in an increasingly competitive market.

Maximizing Efficiency: How Automated Packaging Machines Save Time and Resources

Automated packaging machines have emerged as game-changers for businesses aiming to maximize efficiency. These machines drastically reduce the time spent on packaging processes, allowing companies to allocate resources more effectively. By minimizing human intervention, operational delays caused by manual labor are significantly reduced, leading to quicker turnaround times and increased throughput. This efficiency not only accelerates production rates but also optimizes the overall workflow, creating a streamlined process that is both cost-effective and waste-reducing.

Furthermore, the integration of automation in packaging aligns with the broader trends observed across various industries, where companies leverage technology to enhance their operations. For instance, advancements in AI and robotics are influencing logistics and rehabilitation sectors, demonstrating a systemic shift towards intelligent, data-driven solutions. As businesses face escalating pressures to enhance productivity while also reducing their environmental footprint, automated packaging machines serve as a critical solution to achieving these dual objectives—efficiency and sustainability.

Enhancing Precision: The Role of Automation in Minimizing Packaging Errors

Automation plays a crucial role in enhancing precision in packaging processes. By integrating automated packaging machines, businesses can significantly reduce the likelihood of human error, ensuring that each package is filled, sealed, and labeled consistently. Automation systems are designed to follow precise measurements and guidelines, thus minimizing variations in product quantity and packaging integrity. This not only leads to more reliable products reaching the consumer but also decreases the costs associated with returns and rework due to packaging mistakes.

Furthermore, automated packaging machines employ advanced technologies such as sensors and cameras to monitor the packaging process in real-time. These features enable immediate detection of errors, allowing for quick corrections before products leave the production line. As a result, businesses can ensure high levels of accuracy, which is essential for maintaining brand reputation and customer satisfaction. The enhancement in precision brought by automation ultimately contributes to more efficient operations, as companies can focus on growth without the constant worry of packaging discrepancies affecting their bottom line.

Top 5 Benefits of Using an Automated Packaging Machine for Your Business - Enhancing Precision: The Role of Automation in Minimizing Packaging Errors

| Benefit | Description | Impact on Business |

|---|---|---|

| Increased Efficiency | Automated machines streamline the packaging process, reducing operation time. | Higher throughput and reduced labor costs. |

| Enhanced Precision | Automation minimizes human errors in packaging, ensuring consistent quality. | Improved product integrity and reduced waste due to errors. |

| Cost Reduction | Investment in machinery can lead to lower long-term operational costs. | Increased margins and savings can be reinvested into the business. |

| Scalability | Automated packaging processes can be easily scaled up to meet demand. | Flexibility in production planning and ability to handle large volumes. |

| Improved Workplace Safety | Reduces the need for manual handling, thus decreasing injury risk. | Healthier workforce and lower insurance costs. |

Cost Reduction Strategies: Lower Labor and Material Costs with Automation

Automated packaging machines are revolutionizing the industry by significantly reducing labor and material costs. According to a report by the International Society of Automation, companies that implement automation in their packaging processes can save up to 30% on labor costs. This is primarily due to the decreased need for manual labor, allowing businesses to reallocate their workforce to more value-added tasks. For instance, a manufacturer that previously relied on a team of ten employees for packaging can now optimize with just three operators overseeing automated machinery, resulting in substantial savings.

In addition to labor savings, automation also enhances material usage efficiency. A study by the Packaging Machinery Manufacturers Institute shows that automated systems can lead to a 20% reduction in packaging material waste. This is achieved through precise application techniques and optimized sizing of packaging materials tailored to the products being shipped. As a result, companies not only cut costs associated with raw materials but also contribute to sustainability efforts by minimizing excess waste. Together, these benefits make a compelling case for businesses looking to enhance their bottom line through automated packaging solutions.

Improving Product Consistency: Uniform Packaging for Better Brand Image

Automated packaging machines play a pivotal role in enhancing product consistency, which is crucial for establishing and maintaining a strong brand image. By utilizing these machines, businesses can ensure that each package is uniformly filled, sealed, and labeled. This not only meets customer expectations but also reinforces the brand’s commitment to quality and precision. A uniform appearance in packaging can elevate the perceived value of the product, making it more appealing on the shelves or in online listings.

To maintain consistency, businesses should invest in high-quality automated packaging machines that are tailored to fit their unique product specifications. Regular maintenance and calibration of these machines are essential to avoid discrepancies in package sizes or seal integrity. Additionally, implementing strict quality checks during the packaging process can help catch any irregularities before products reach consumers.

Another effective tip is to standardize packaging materials and designs. Using the same type of materials and adhering to brand guidelines in design ensures that every package will look and feel the same, regardless of the production batch. This fosters customer trust and loyalty, as they know what to expect with every purchase. Investing in automated packaging not only saves time and labor costs but also plays a crucial role in establishing a consistent and professional brand image.

Top 5 Benefits of Using an Automated Packaging Machine

Boosting Scalability: Adapting Automated Solutions for Growing Business Needs

As businesses expand, the need for scalable solutions becomes increasingly evident.

Automated packaging machines are a game-changer, providing the

flexibility and efficiency required to keep pace with growing demands. According to a report by Smithers Pira,

the global market for automated packaging machinery is expected to reach $70 billion by 2025,

with a compound annual growth rate (CAGR) of 4.4%. This growth underscores

the need for businesses to rethink their packaging processes to enhance productivity without compromising quality.

Automated packaging machines are a game-changer, providing the

flexibility and efficiency required to keep pace with growing demands. According to a report by Smithers Pira,

the global market for automated packaging machinery is expected to reach $70 billion by 2025,

with a compound annual growth rate (CAGR) of 4.4%. This growth underscores

the need for businesses to rethink their packaging processes to enhance productivity without compromising quality.

Automated solutions adapt seamlessly to fluctuations in production volume, making them ideal for companies experiencing rapid growth. By leveraging automation, businesses can reduce labor costs by up to 50% and improve packaging speed by 25% or more, as noted by a study from the Packaging Automation Market. Additionally, with advancements like machine learning and IoT integration, these machines can be customized to meet specific packaging requirements, ensuring that businesses can scale their operations effectively while responding to market changes swiftly. Ultimately, investing in automated packaging not only streamlines operations but also positions companies to thrive in an increasingly competitive landscape.

Related Posts

-

Top 10 Custom Packaging Machines to Boost Your Business Efficiency in 2023

-

Revolutionizing the Food Industry How Food Packaging Machines Enhance Freshness and Sustainability

-

Revolutionizing Supply Chains: The Future of Industrial Packaging Equipment Explained

-

Revolutionizing Packaging: How Automatic Bagging Machines Enhance Efficiency and Precision in Industries

-

Mastering Efficiency: How VFFS Machines Revolutionize Packaging Processes for Modern Businesses

-

Innovative Material Handling Carts for Efficient Workplace Organization and Productivity