Top 10 Benefits of Using a Vertical Form Fill Seal Machine for Your Business

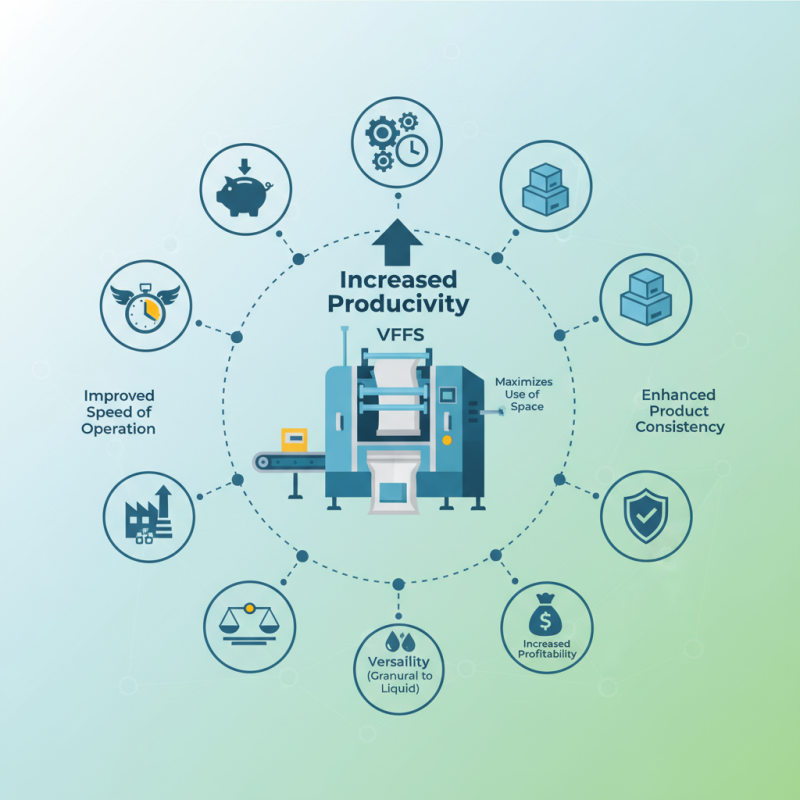

In the fast-paced world of production and packaging, businesses are continually seeking innovative solutions to enhance efficiency and reduce costs. One of the most significant advancements in this realm is the vertical form fill seal machine. According to industry expert Dr. Emily Carter, “The vertical form fill seal machine revolutionizes packaging by streamlining processes and ensuring precise product filling, leading to increased productivity.” This technology not only maximizes the use of space but also offers versatility in handling a wide array of products, from granular substances to liquids.

Utilizing a vertical form fill seal machine can yield numerous advantages for manufacturers, including reduced labor costs, improved speed of operation, and enhanced product consistency. As businesses aim to meet the growing demands of consumers while maintaining profitability, adopting this advanced machinery offers a competitive edge. In this article, we will delve into the top ten benefits of using a vertical form fill seal machine, demonstrating how it can transform packaging operations and drive success in today's dynamic market landscape.

Overview of Vertical Form Fill Seal Machines

Vertical Form Fill Seal (VFFS) machines are essential tools in modern packaging processes, known for their efficiency and versatility. These machines operate by forming a flat film into a tube, filling it with the desired product, and then sealing it all in one seamless operation. This streamlining of the packaging process significantly reduces labor costs and increases productivity, making it an ideal solution for businesses looking to optimize their production lines.

One of the key advantages of VFFS machines is their adaptability to various packaging materials and product types. They can handle liquids, solids, and even powders, which makes them suitable for a wide range of industries, from food and beverages to pharmaceuticals and pet care. Additionally, VFFS machines can be customized with different sealing technologies and film materials, allowing businesses to meet specific packaging requirements while maintaining high standards of quality and efficiency. Their compact design also saves valuable floor space, making them an attractive option for operations of all sizes.

Increased Efficiency in Packaging Processes

A vertical form fill seal (VFFS) machine significantly enhances efficiency in packaging processes, making it an invaluable asset for businesses aiming to streamline operations. This advanced technology automates the entire packaging cycle, from forming the bag to filling it with the product and sealing it in a single motion. By eliminating the need for manual interventions, businesses can reduce labor costs and minimize human errors, leading to a more reliable packaging system.

The speed at which VFFS machines operate further contributes to increased productivity. These machines can pack products at a rapid pace, allowing companies to meet high demand without compromising on quality. Additionally, the compact design of VFFS machines helps optimize floor space within production facilities. This not only increases operational efficiency but also enhances the overall workflow, enabling manufacturers to allocate resources more effectively. Ultimately, the integration of a vertical form fill seal machine can transform packaging operations, making them faster, more efficient, and more adaptable to changing market needs.

Cost Savings Associated with Automation

The integration of a vertical form fill seal (VFFS) machine into your business operations can lead to significant cost savings, primarily through automation. Traditional packaging methods often involve extensive manual labor and time-consuming processes that can inflate operational expenses. By automating these packaging tasks, a VFFS machine allows businesses to reduce labor costs, minimize human error, and enhance overall efficiency. This direct transition to a more automated system often results in lower wage costs and less need for overtime, which can substantially ease the strain on a company's budget.

Moreover, the operational efficiency brought about by VFFS machines translates into reduced production time. This machine can swiftly handle a variety of packaging tasks with minimal downtime, allowing for higher output and faster turnover. Consequently, businesses can respond more quickly to demand fluctuations, reducing the costs associated with stocking and storage of products. The ability to streamline operations also optimizes resource utilization, ensuring that materials and energy are used more effectively. In effect, implementing a vertical form fill seal machine not only cuts direct labor costs but also enhances the overall production process, leading to substantial savings and increased profitability in the long run.

Enhanced Product Freshness and Shelf Life

The use of a vertical form fill seal (VFFS) machine is revolutionizing the packaging industry by enhancing product freshness and extending shelf life. One of the primary advantages of this technology is its ability to create airtight seals that protect products from external contaminants. By minimizing exposure to air, moisture, and light, VFFS machines ensure that perishable items, such as snacks, powders, and liquids, maintain their quality for a longer period. This is particularly beneficial for businesses that prioritize delivering fresh products to consumers, as it enhances customer satisfaction and reduces wastage.

Additionally, VFFS machines contribute to consistent packaging that helps maintain product integrity over time. The precision engineering of these machines allows for uniform packaging sizes, ensuring that each item is securely sealed without excess air trapped inside. This uniformity not only aids in extending the shelf life but also facilitates easier inventory management and reduces packing errors. By employing VFFS technology, businesses can effectively safeguard their products while promoting an image of quality and reliability in the marketplace, making it an indispensable asset for maintaining product freshness in a competitive environment.

Versatility for Various Packaging Needs

Vertical Form Fill Seal (VFFS) machines have revolutionized the packaging industry by offering unmatched versatility for various packaging needs. The adaptability of VFFS systems allows businesses to efficiently package a wide range of products, from granules and powders to liquids and snacks. According to a report by MarketsandMarkets, the global packaging machinery market is projected to reach $45 billion by 2025, with VFFS machines playing a crucial role due to their efficiency and flexibility. This versatility enables companies to respond quickly to changing consumer demands and market trends, making them a strategic investment in an increasingly competitive landscape.

Furthermore, VFFS machines support different packaging materials, including films, laminated materials, and biodegradable options, catering to the growing demand for sustainable solutions. A study by the Flexible Packaging Association indicates that the flexible packaging market is expected to grow annually by 4.1% over the next few years, driven by consumer preferences for lightweight and sustainable packaging. This flexibility in packaging options not only meets diverse product requirements but also enhances shelf appeal and reduces packaging waste, aligning with the sustainability goals of many businesses today. Overall, the VFFS technology empowers enterprises to maintain operational efficiency while adapting to the ever-evolving market needs.

Top 10 Benefits of Using a Vertical Form Fill Seal Machine for Your Business - Versatility for Various Packaging Needs

| Benefit | Description | Applicable Industries | Cost Efficiency |

|---|---|---|---|

| High Speed | Increased production rates, saving time. | Food, Pharmaceuticals | Reduces labor costs |

| Versatility | Can package different types of products. | Beverages, Snacks | Minimizes equipment investment |

| Consistent Quality | Uniform packaging that meets standards. | Cosmetics, Chemicals | Less waste |

| Space Efficiency | Compact design suitable for small areas. | Grocery, Retail | Lower overhead costs |

| Reduced Labor | Automation decreases dependency on manual labor. | Food Processing, Electronics | Cost savings on salaries |

| Ease of Use | User-friendly interfaces for quick setup. | Healthcare, E-commerce | Fewer training costs |

| Customizable | Flexibility to adjust for various products. | Pet Food, Industrial | Optimal resource allocation |

| Improved Safety | Minimized handling reduces risk of injury. | Construction, Agriculture | Potential for lower insurance costs |

| Environmentally Friendly | Use of recyclable materials reduces waste. | Food Service, Cosmetics | Saves resources in the long term |

Related Posts

-

Revolutionizing the Food Industry How Food Packaging Machines Enhance Freshness and Sustainability

-

Top 10 Packaging Automation Equipment for Streamlining Your Production Process

-

Revolutionizing Supply Chains: The Future of Industrial Packaging Equipment Explained

-

Revolutionizing Packaging: How Automatic Bagging Machines Enhance Efficiency and Precision in Industries

-

Exploring the Future of Conveyor Systems in Automation and Smart Manufacturing

-

Mastering Efficiency: How VFFS Machines Revolutionize Packaging Processes for Modern Businesses