2026 How to Choose the Best Automatic Packaging Machines for Your Business?

In today's fast-paced market, businesses increasingly rely on automatic packaging machines. These machines streamline processes and enhance efficiency. Choosing the right model is crucial for success. Each type of machine offers distinct features and capabilities. Understanding your specific needs can be challenging.

Consider factors like speed, size, and product type. Some packaging machines cater to liquid products. Others work best with solids or powders. This variety can lead to confusion. Also, maintenance requirements vary widely between models. A reliable machine should fit seamlessly into your workflow.

Reflect on your budget as well. High-quality automatic packaging machines may demand a higher initial investment. However, the long-term savings often justify the cost. Pay attention to user reviews and case studies. Real-world performance provides valuable insights into each machine's effectiveness. Ultimately, making an informed choice can significantly impact your company's operational success.

Understanding Different Types of Automatic Packaging Machines Available

When selecting automatic packaging machines, understanding the various types available is crucial. Each type serves different needs and industries. For instance, horizontal flow wrappers are ideal for packing food products. This machine maintains product integrity while offering high-speed output.

Vertical form-fill-seal machines, on the other hand, are versatile and can handle liquids, powders, and granules effectively.

According to industry experts, the global automatic packaging market is projected to reach $50 billion by 2028, indicating a strong demand for efficient packaging solutions. However, businesses often overlook the importance of machine compatibility with their production line. This can lead to operational hiccups. Evaluating the space you have and the volume you need is critical.

Tips: Consider trial runs before making a purchase. This allows you to assess machine performance without a full commitment. Another point is that long-term maintenance costs are often neglected, but they can significantly affect your budget. Always seek machines that come with robust support and have a reputation for reliability.

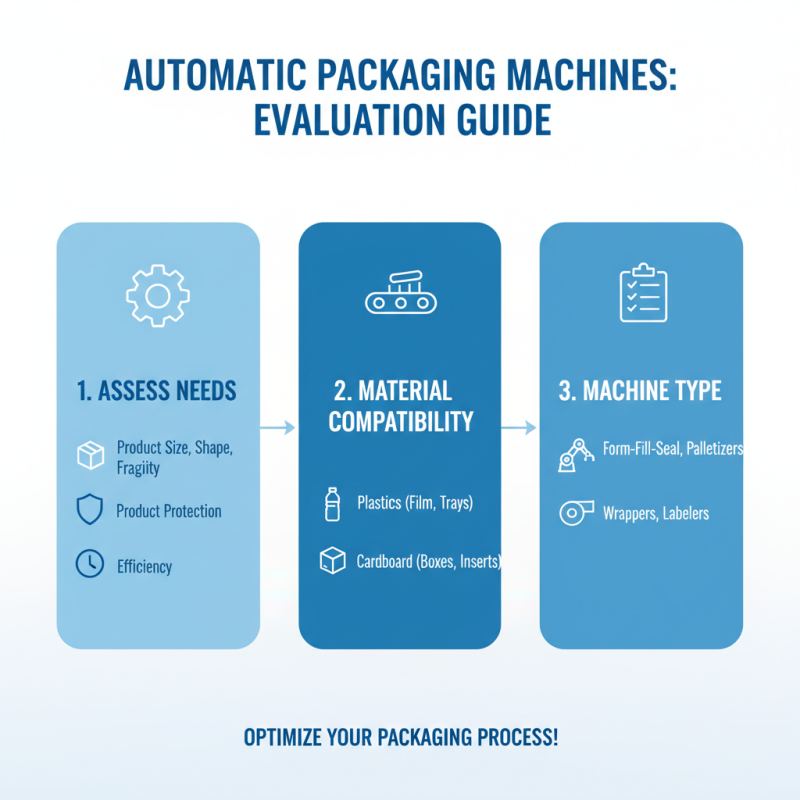

Assessing Your Business Needs for Packaging Solutions

When evaluating automatic packaging machines for your business, begin by assessing your specific needs. Consider factors like product size, shape, and fragility. Your packaging solution should protect the product while being efficient. Look at the types of materials you plan to use. Different machines accommodate various packaging materials, from plastic to cardboard.

**Tips:** Always request samples from suppliers. Testing a machine on your actual products can reveal potential issues early. Don’t overlook the importance of speed. It affects your production line and ultimately your bottom line.

Think about the future as well. Will your production volume increase? Can the machine adapt to changes in product design? Reflect on maintenance needs too. A machine with complex maintenance requirements may cause unexpected downtime. Prioritize durability and reliability in your long-term investment. This careful consideration now will pay off later.

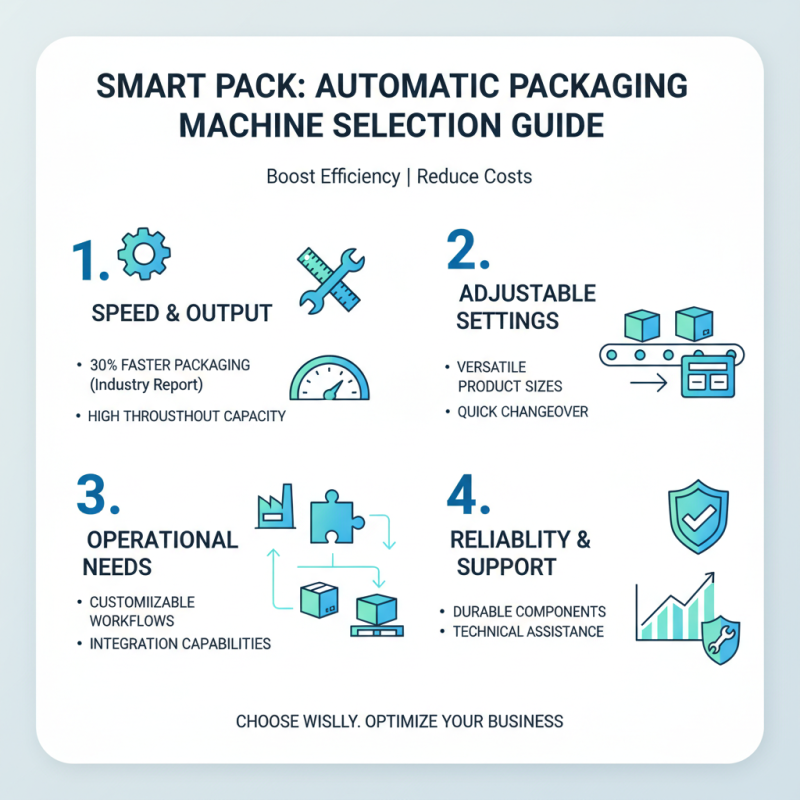

Key Features to Look for in Automatic Packaging Machines

When selecting automatic packaging machines for your business, it’s vital to consider key features that enhance efficiency. According to a recent industry report, businesses can improve their packaging speed by nearly 30% with the right equipment. Targeting your operational needs is crucial. Look for machines with adjustable settings to handle a variety of product sizes. Versatility can save time and reduce costs.

Another important feature is the quality of the sealing mechanism. A secure seal prevents product spoilage. Research shows that improper sealing can lead to a 5% increase in returns. Implement machines that provide consistent seal integrity. This ensures product safety and customer satisfaction.

**Tip: Always test the machine with your products before purchase.** This helps identify any potential issues. Consider the machine’s ease of maintenance too. A complex system can lead to long downtimes. Simplified maintenance can lower operational risk.

Automation is not just about speed. Customization options are also pivotal. Machines that allow custom programming cater to specific packaging requirements. However, don’t overlook the learning curve involved with advanced technology. Analyze your team's capacity to adapt. Balancing innovation with practicality is essential for successful deployment.

Evaluating Reliability and Maintenance Needs of Packaging Equipment

When selecting automatic packaging machines, reliability is a crucial consideration. Reliable equipment minimizes downtime and increases productivity. To check reliability, investigate the machine’s operating history and seek online reviews. Understanding how often a machine needs repairs can save your business time and money.

Maintenance needs also play a vital role. Some machines require regular servicing, which can be resource-intensive. Others might demand minimal upkeep. Assess your team’s capacity to perform maintenance. Are your staff trained? Or will you need to hire specialists? Consider these factors seriously when making your choice.

Tips: Regular maintenance schedules keep machines running smoothly. Train your staff to spot early warning signs of wear. Investing in a machine with user-friendly designs may reduce future training costs and downtime.

Cost Considerations and ROI Analysis for Packaging Machines

When choosing automatic packaging machines, cost considerations are paramount. Start by evaluating the initial investment. Machines vary widely in price. A basic model may cost less, but advanced options provide more features. Think about your production scale. Larger operations may justify a higher upfront cost.

Return on Investment (ROI) is crucial. Calculate potential savings in labor costs. Automated systems often reduce workforce expenses. Consider efficiency improvements too. Faster machines can increase output. Examine how much time you save daily. A thorough analysis reveals true value.

Tips: Always factor in maintenance costs. Some machines require more upkeep than others. Watch for hidden fees, like installation and training. Assess your needs before committing. Are you prepared for changes in workflow? Reflect on your business’s future needs. This decision impacts long-term success.

Cost Considerations and ROI Analysis for Automatic Packaging Machines

Related Posts

-

Why Industrial Packaging Equipment is Essential for Modern Business Success?

-

What is Packaging Equipment and How Does it Work?

-

Top Tips for Choosing Packaging Equipment Systems for Your Business?

-

Top 10 Automated Packaging Machines You Need to Know About in 2023

-

2026 How to Choose the Right Industrial Packaging Machines for Your Business?

-

Revolutionizing Efficiency: How Automated Packaging Machines Transform Your Production Line