Best Butterfly Valves for Sale What You Need to Know

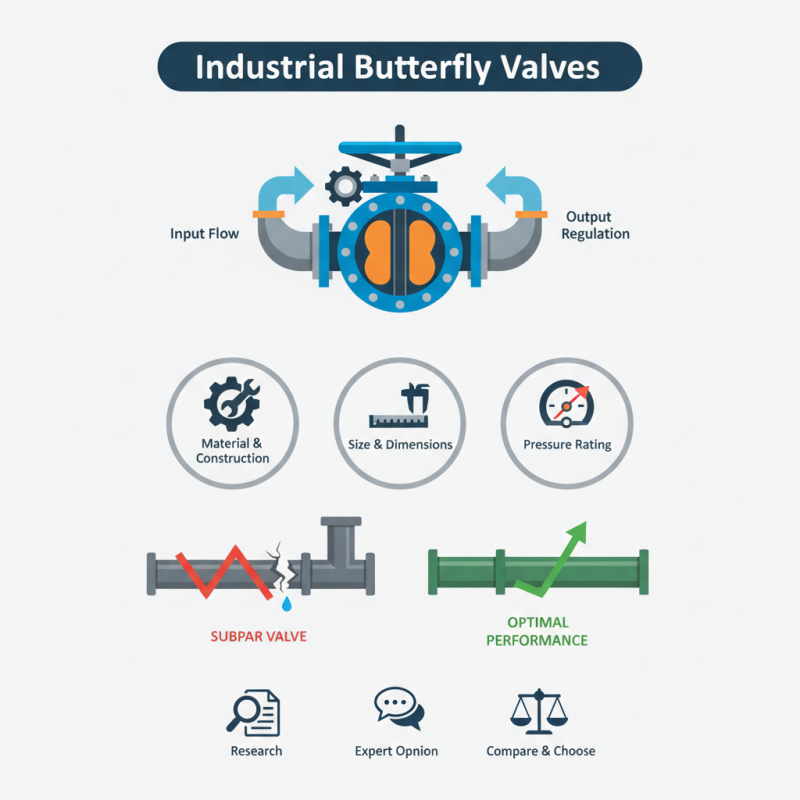

When it comes to industrial applications, finding the right butterfly valves for sale is crucial. These valves play a key role in regulating flow. They are well-known for their durability and efficiency. However, not every option on the market meets the required standards.

Choosing the right butterfly valve can be daunting. Factors like material, size, and pressure ratings all come into play. It's essential to consider these elements before making a purchase. Remember, quality matters. A subpar valve may lead to leaks or failures over time.

Many buyers rush into decisions, overlooking vital details. This could lead to costly consequences. It’s wise to conduct thorough research. Seek opinions from those experienced in the field. Compare different products and manufacturers. The right choice will ensure optimal performance and longevity.

Understanding Butterfly Valves: Types and Applications

Butterfly valves are essential components in various industries. They offer control over airflow and liquid flow. Understanding their types is critical for effective application. There are several types of butterfly valves, including concentric, double-eccentric, and triple-eccentric designs. Each serves unique purposes and has specific advantages.

For instance, concentric butterfly valves are mainly used in water systems. They provide good sealing at low-pressure applications. According to industry data, they deliver effective performance in situations where pressure does not exceed 150 psi. In contrast, double-eccentric and triple-eccentric valves excel in high-pressure applications, boasting superior sealing capabilities and durability. They can withstand operating pressures over 300 psi, making them ideal for gas and steam services.

**Tip:** Always consider the medium you intend to handle. This affects the material selection of the valve. Use valves made from corrosion-resistant materials for aggressive fluids. It's crucial to evaluate the operating environment. Temperature fluctuations can impact valve performance and longevity.

Understanding these variations ensures you make informed choices. Many users overlook maintenance. Regular checks and services are vital for longevity. Inadequate maintenance can lead to valve failure, which may lead to costly repairs. Always be realistic about your application needs. Sometimes, the best choice is not the most expensive option but the one that fits your specific requirements.

Best Butterfly Valves Types and Their Applications

This chart illustrates the different types of butterfly valves and their corresponding applications measured by the number of use cases. Understanding these types can help in selecting the best butterfly valve for various industrial applications.

Key Features to Consider When Choosing Butterfly Valves

When choosing butterfly valves, several key features stand out. The seat material is crucial. Common options include EPDM, NBR, and PTFE. Each material offers different temperature and chemical resistance. Research shows that the wrong material can lead to failures. For instance, using NBR in a high-temperature application could compromise the valve's integrity.

Another important aspect is the valve size and pressure rating. Manufacturers report that improper sizing results in inefficiencies. A valve too small can restrict flow. Conversely, one too large may not seal properly. It is essential to match the valve with the specific system requirements.

Installation and maintenance practices also deserve attention. A study highlighted that improper installation can reduce a valve’s lifespan significantly. Regular checks and maintenance should be a priority. They ensure optimal performance and reduce the likelihood of unexpected failures. Attention to these details can enhance reliability and avoid costly replacements.

Benefits of Using Butterfly Valves in Industrial Systems

Butterfly valves are essential in many industrial systems. They offer great flow control capabilities. Their design allows quick opening and closing. This feature is particularly useful in processes needing rapid adjustments. Additionally, they require less space than other valve types. This can be a significant advantage in cramped environments.

One major benefit of butterfly valves is their energy efficiency. They create lower pressure drops compared to other valves. This efficiency can lead to reduced operating costs over time. In applications like water treatment and chemical processing, these savings can be substantial. However, ensuring proper installation is crucial. Incorrect setups can lead to leaks or inefficient operation.

Tips: Regular maintenance checks are vital. Inspect for signs of wear or damage. Adjust tightly to avoid flow issues. Remember, a small oversight can lead to bigger problems down the line. Keeping records of maintenance can help in identifying recurring issues. Regular training for staff on valve operation can enhance overall efficiency.

Guide to Selecting the Right Butterfly Valve Size and Material

When selecting a butterfly valve, size and material are crucial. The right size ensures optimal flow and pressure control. According to industry reports, improper sizing can lead to a 20-30% drop in efficiency. Start by analyzing the pipeline's diameter and flow rate. A valve that’s too small restricts flow, while an oversized valve can create turbulence.

Material selection is equally important. Common materials include cast iron, stainless steel, and PVC. Each material has unique properties. For example, stainless steel offers corrosion resistance. However, it’s often more expensive. Reports indicate that 15% of valve failures stem from incorrect material choice. Always consider your application environment before making a decision.

Tips: Always check compatibility with fluids. Validate pressure ratings. When in doubt, consult a professional. Understanding your needs is key. Remember, a small error in sizing or material can lead to significant changes in performance. Reflect on your project requirements carefully to avoid costly mistakes.

Top Manufacturers and Brands of Butterfly Valves on the Market

When considering butterfly valves, it's essential to know the top manufacturers and brands available. These companies often specialize in different areas, producing valves suited for various applications. Look for designs that emphasize durability and performance, especially in critical projects. The range of materials, such as PVC, stainless steel, and cast iron, can greatly affect the valve's longevity and effectiveness.

Quality varies among manufacturers, and not all meet industry standards. Some may cut corners with cheaper materials, which can lead to early failures. It's crucial to research each brand reputation thoroughly. Read reviews and check certifications. Finding a valve that balances cost and quality can be challenging. In some instances, you might have to compromise on features to stay within budget.

Consider the specific requirements of your project. Different applications may require different valve features. Some might need a soft-seated option for better sealing, while others may demand a more robust design. Evaluating your needs critically can help you choose wisely. The market is vast, and not every product will suit your purpose perfectly. A little reflection on your choices can go a long way.

Best Butterfly Valves for Sale What You Need to Know

| Valve Size (inches) | Body Material | Disc Material | Pressure Rating (PSI) | Temperature Range (°F) | End Connection Type |

|---|---|---|---|---|---|

| 2" | Cast Iron | EPDM | 150 | -20 to 300 | Flanged |

| 4" | Stainless Steel | PTFE | 200 | -20 to 400 | Wafer |

| 6" | Aluminum | NBR | 150 | -40 to 250 | Butt Weld |

| 8" | PVC | PVC | 100 | -20 to 140 | Socket Weld |