10 Best Conveyor Parts for Efficient Material Handling in Warehouses?

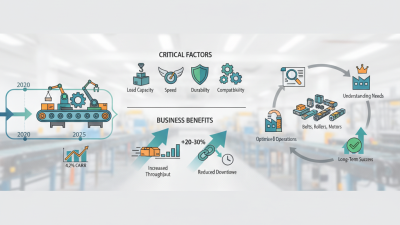

In the fast-paced world of warehouse operations, efficient material handling is essential. Conveyor parts play a vital role in this process. According to John Smith, an expert in conveyor systems, "The right conveyor parts can drastically improve productivity." This statement underlines the importance of choosing the best components for any material handling system.

When selecting conveyor parts, one must consider various factors. Factors include durability, compatibility, and cost-effectiveness. Each component, from belts to rollers, must work seamlessly together. Neglecting to do so can lead to inefficiencies. It's not just about having the latest technology; understanding how parts interact is crucial.

Many warehouses suffer from outdated or mismatched conveyor parts. Such issues can cause delays and increase operational costs. Embracing modern solutions means investing in high-quality conveyor parts. Failing to adapt may lead to falling behind competitors. Ultimately, the right choices can lead to smoother operations and a more productive warehouse environment.

Top Conveyor Belt Types for Streamlined Material Movement

In warehouses, conveyor belts play a crucial role in efficient material handling. Various types of conveyor belts help streamline processes. For instance, roller bed conveyors reduce friction, allowing heavier items to move smoothly. According to a report by the Material Handling Industry of America, 70% of U.S. warehouses utilize some form of conveyor system.

Flexible conveyor systems are also effective. They adapt to different warehouse layouts. This versatility helps in optimizing space usage. An internal study on warehouse efficiency revealed that automation can increase productivity by 30%. However, not all warehouses implement these systems effectively. Some still stick with outdated methods.

Understanding the different types of conveyor belts is essential. Modular belts, for instance, can handle diverse material shapes. Yet, they require regular maintenance. A survey indicated that 25% of warehouses face downtime due to improper handling. Total costs can rise without proper planning. Investing in the right type of conveyor can significantly impact operations.

10 Best Conveyor Parts for Efficient Material Handling

Essential Conveyor Rollers for Enhanced Durability and Efficiency

Conveyor rollers are vital for efficient material handling in warehouses. They ensure smooth movement of products along conveyor systems. Durable rollers reduce maintenance needs and improve productivity. A well-maintained roller can last years. But, how do you choose the right one?

Material choice matters. Steel rollers offer strength but may corrode. Plastic rollers resist corrosion but are less durable. Think about the load capacity. Too heavy a load on the wrong roller can cause failure. Roller diameter impacts performance too. A larger diameter roller moves goods more efficiently.

Regular inspections are crucial. Wear and tear can sneak up on you. A worn roller can lead to delays. It’s easy to overlook this part, yet its importance is undeniable. Investing in quality rollers pays off. They enhance your system's efficiency. However, it's important to remember that no roller is perfect. Regularly reassess your choices. Adapt to changes in your inventory. Maintaining efficiency is an ongoing process.

10 Best Conveyor Parts for Efficient Material Handling in Warehouses

| Part Name | Material Type | Load Capacity (lbs) | Durability Rating | Efficiency Factor |

|---|---|---|---|---|

| Roller Conveyor | Steel | 500 | High | 95% |

| Chain Drive | Plastic | 300 | Medium | 85% |

| Belt Conveyor | Rubber | 400 | High | 90% |

| Inclined Roller | Aluminum | 350 | Medium | 88% |

| Gravity Roller | Galvanized Steel | 450 | High | 92% |

| Powered Roller | Steel | 600 | High | 94% |

| Modular Conveyor | Plastic | 250 | Low | 80% |

| Flexible Conveyor | Steel | 300 | Medium | 87% |

| Food Grade Conveyor | Stainless Steel | 350 | High | 93% |

| Screw Conveyor | Carbon Steel | 400 | High | 91% |

Effective Conveyor Pulleys: Key Components for Smooth Operations

Effective conveyor pulleys play a crucial role in warehouse operations. They facilitate the movement of materials efficiently. A well-designed pulley system allows for seamless transitions between different conveyor sections. This ensures that operations run smoothly without frequent disruptions.

Different types of pulleys serve various purposes. For instance, drive pulleys are essential for powering the conveyor belt. They provide the necessary force to move materials. However, if improperly aligned, they can cause belt wear. This often leads to costly maintenance. Take the time to inspect and realign pulleys regularly.

Moreover, tensioning pulleys maintain the correct tension on the conveyor belt. Insufficient tension can result in slippage. This can halt operations and frustrate workers. It’s vital to monitor tension levels closely. Utilize a simple tension indicator to track any changes. Regular feedback and adjustments can prevent larger issues. Actively managing these components ensures the conveyor system remains efficient and reliable.

Must-Have Conveyor Chains for Reliable and Continuous Transport

Conveyor chains play a crucial role in efficient material handling. They ensure reliable and continuous transport of goods in warehouses. Choosing the right chains can improve productivity. However, selection can be tricky with so many options available. It’s essential to consider factors like load capacity, speed, and maintenance requirements.

Material handling is not without challenges. Some chains may wear quicker than expected. Regular inspections are necessary to avoid unexpected breakdowns. A worn chain can lead to delays and reduced efficiency. Operators must be vigilant about signs of wear, like unusual noise or slipping. These issues can often indicate deeper problems.

In addition to reliability, durability is key. Chains should withstand various environmental conditions. In humid or dusty settings, resistance to corrosion becomes vital. Warehouse operators must balance cost and quality. Sometimes it's tempting to save money, but investing in quality can prevent future headaches. Always reassess the performance of your chosen chains. It’s important to remain open to adjustments for continuous improvement in operations.

Innovative Conveyor Controls for Improved Handling and Automation

Innovative conveyor controls can transform material handling in warehouses. These systems enhance efficiency and precision. They allow for real-time monitoring of product flow. Operators can detect issues quickly, reducing downtime. Automation streamlines operations, but it requires careful planning. A well-designed control system integrates smoothly with existing equipment.

One significant feature is the use of sensors. These devices can detect objects and adjust speeds accordingly. For instance, if a jam occurs, the system can halt conveyor movement instantly. This reduces damage and saves time. However, implementing these solutions isn't without challenges. Staff need training to adapt to new technologies. Resistance to change can create obstacles that slow progress.

Another critical element is data analysis. Gathering and interpreting data can optimize workflows. Yet, interpreting vast data sets requires expertise. Overlooking small details in this process can lead to inefficiencies. Balancing automation with human oversight is key. While technology improves handling, it shouldn't replace skilled workers entirely. A hybrid approach often yields the best results.

Related Posts

-

2025 How to Choose the Right Conveyor Parts for Your Business Needs

-

Top 5 Benefits of Using an Automated Packaging Machine for Your Business

-

Top 10 Best Material Handling Equipment for Efficient Warehouse Operations

-

10 Best Filling Machines for Efficient Packaging Solutions?

-

Revolutionizing the Food Industry How Food Packaging Machines Enhance Freshness and Sustainability

-

Top 10 Best Material Handling Carts for Efficient Warehouse Solutions