Top 10 Best Material Handling Equipment for Efficient Warehouse Operations

In the increasingly competitive landscape of warehouse operations, the importance of efficient material handling equipment cannot be overstated. According to a recent report by the Material Handling Industry of America (MHIA), the material handling equipment market is projected to grow at a compound annual growth rate of 6.4% from 2021 to 2026, driven by the rising demand for automation in warehouses and distribution centers. As operations become more complex, the right selection of material handling equipment becomes critical to optimize workflow, reduce costs, and enhance overall productivity.

Industry expert Dr. John McHugh, a renowned figure in material handling, emphasizes that “the evolution of material handling equipment is shaping the future of warehouse management.” His insights illuminate the need for businesses to adopt cutting-edge solutions that not only streamline processes but also accommodate the growing demands of e-commerce and supply chain operations. By leveraging advanced material handling equipment, companies can achieve higher efficiency levels and adapt to the ever-changing market dynamics.

By exploring the top 10 best material handling equipment options, this article aims to provide warehouse managers and operators with valuable insights into how they can enhance their operations. From automated guided vehicles (AGVs) to inventory management software, the right choices can make a significant difference in achieving operational excellence in today’s fast-paced environment.

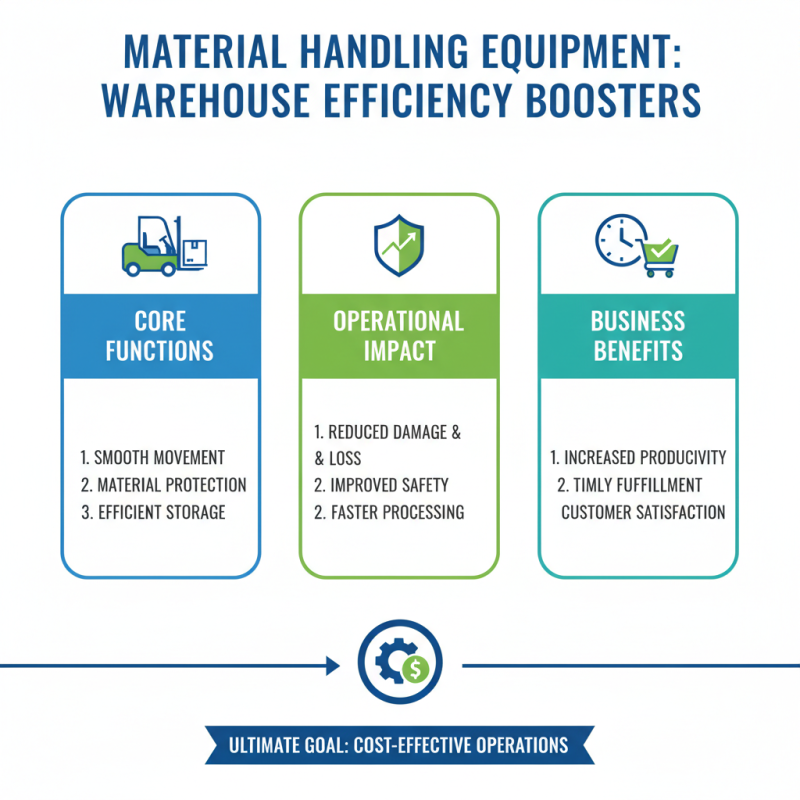

Importance of Material Handling Equipment in Warehousing Efficiency

Material handling equipment plays a crucial role in enhancing the operational efficiency of warehouses. By facilitating the smooth movement, protection, and storage of materials, this equipment minimizes the risk of damage and loss while improving safety during operations. In a fast-paced warehouse environment, the right tools enable workers to handle goods more effectively, reducing the time and labor needed for loading, unloading, and transporting items. This streamlining of procedures not only boosts productivity but also contributes to timely order fulfillment, a key factor in customer satisfaction.

Moreover, the integration of modern material handling solutions fosters adaptability for future challenges. As warehouses evolve to accommodate new technologies and increasing volumes of inventory, the flexibility provided by innovative equipment allows facilities to respond to changing demands swiftly. Automatic systems, ergonomic designs, and modular equipment formats enhance worker ergonomics and reduce fatigue, further ensuring a more efficient workflow. The significance of material handling equipment, therefore, extends beyond mere functionality; it is central to building a resilient and efficient warehouse operation that can keep pace with the dynamic landscape of supply chain and logistics management.

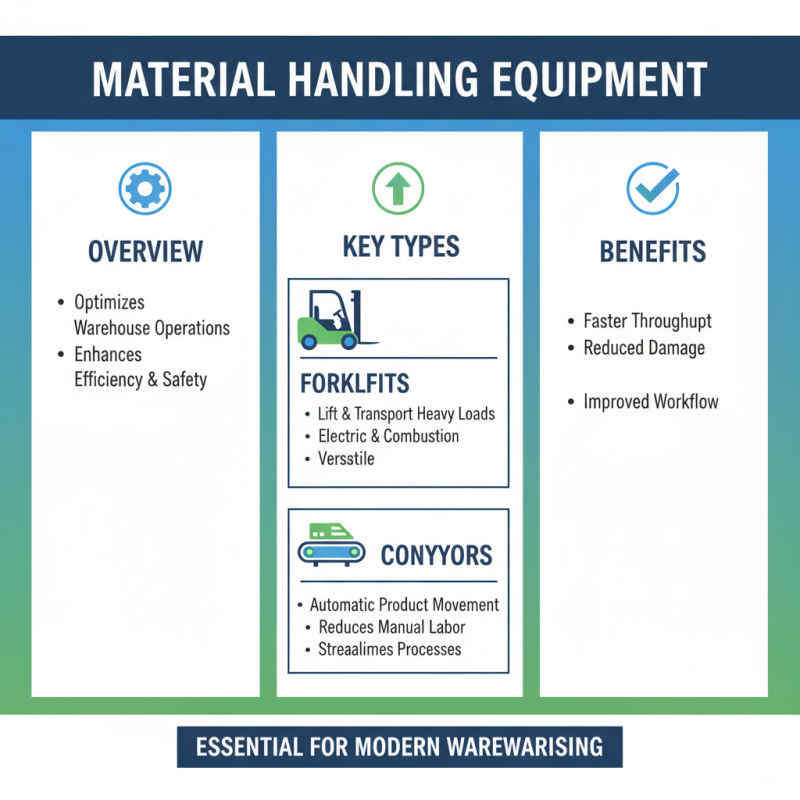

Types of Material Handling Equipment and Their Applications

Material handling equipment is essential for optimizing warehouse operations, enhancing efficiency, and ensuring the safe movement of goods. Among the various types of material handling equipment, forklifts are one of the most commonly used tools, designed to lift and transport heavy loads. They come in different configurations, including electric and internal combustion options, making them versatile for various warehouse environments. Conveyors, another crucial type, facilitate the automatic movement of products across different areas of the warehouse, significantly reducing manual labor and streamlining processes.

In addition to forklifts and conveyors, pallet jacks are vital for handling pallets of goods in tight spaces, allowing employees to easily transport items without the need for a larger vehicle. Furthermore, shelving and racking systems provide efficient storage solutions, maximizing vertical space in warehouses and enabling better organization of inventory. Automated guided vehicles (AGVs) are becoming increasingly popular, as they enhance the precision of material transport while reducing the need for human intervention. By understanding the different types of material handling equipment and their specific applications, warehouse operators can select the right tools to enhance productivity and safety in their operations.

Key Features to Consider When Selecting Equipment for Warehouses

When selecting material handling equipment for warehouses, it's essential to consider several key features that can significantly enhance operational efficiency. A recent industry report highlights that nearly 75% of warehouses are focusing on automation as a crucial aspect of their equipment selection (B2B Research, 2023). Automation not only reduces labor costs but also minimizes errors during inventory management and order fulfillment. Therefore, prioritizing equipment that integrates seamlessly with automated systems can lead to improved throughput and productivity.

Another critical feature is the equipment's load capacity and ergonomic design. According to the Ergonomics and Human Factors Division of the American Society of Mechanical Engineers, ergonomically designed equipment can reduce worker injuries by up to 50% (ASME, 2023). This is vital in warehouses where repetitive tasks can lead to strains and sprains among employees. Ensuring that the selected equipment has adjustable settings and can accommodate various load sizes can help maintain a safer and more efficient working environment.

In addition to load capacity and ergonomic design, considerations such as maintenance requirements and energy efficiency play a pivotal role in the long-term viability of material handling equipment. A report from the Material Handling Industry of America states that energy-efficient equipment can lead to a 30% reduction in operational costs over time (MHIA, 2023). Investing in equipment that is not only effective but also easy to maintain can ensure that a warehouse operates smoothly without incurring unexpected downtime and repair costs.

Top 10 Best Material Handling Equipment for Efficient Warehouse Operations

This chart illustrates the efficiency ratings of various material handling equipment used in warehouse operations. A higher rating indicates better performance and effectiveness in handling materials efficiently.

Top 10 Material Handling Equipment for Streamlined Operations

Efficient warehouse operations hinge on the right material handling equipment. Streamlined operations not only enhance productivity but also improve safety and reduce operational costs. Among the most essential equipment are pallet jacks and forklifts, which facilitate the easy transportation of heavy goods. Additionally, conveyor systems play a pivotal role in automating the movement of items, significantly minimizing manual labor and the potential for injuries.

When selecting material handling equipment, consider the layout of your warehouse and the types of products being moved. One tip is to maintain clear pathways to avoid congestion; this ensures smooth operations and faster processing times. Another essential tip is to regularly train staff on equipment usage and safety practices to prevent accidents and injuries. Implementing routine maintenance schedules for your equipment can further enhance operational efficiency and extend the lifespan of your tools, ultimately supporting a seamless warehousing process.

Top 10 Best Material Handling Equipment for Efficient Warehouse Operations

| Equipment | Type | Max Load Capacity | Key Features | Ideal For |

|---|---|---|---|---|

| Forklift | Powered | 5,000 lbs | Maneuverable, effective for lifting | Heavy-duty warehouses |

| Pallet Jack | Manual | 4,500 lbs | Compact, easy to use | Small to medium warehouses |

| Conveyor System | Automated | Variable | Continuous movement of goods | High-volume operations |

| Stackers | Powered/Manual | 3,000 lbs | Compact design for tight spaces | Narrow aisles |

| Forklift Attachments | Accessory | - | Versatile for various loads | Multi-purpose use |

| Carts | Manual | 1,000 lbs | Lightweight, easy to maneuver | Small item transport |

| Shelving Units | Storage | - | Adjustable storage options | Organizing items |

| Hoists | Powered/Manual | 2,000 lbs | Lifting heavy items | Heavy-duty lifting |

| Order Pickers | Powered | 3,500 lbs | Ergonomic design for operators | Order fulfillment |

| Trolleys | Manual | 500 lbs | Simple transportation | General handling |

Best Practices for Maintenance and Safety in Material Handling Equipment

Maintaining the efficiency of material handling equipment is crucial for any warehouse operation. According to industry reports, properly maintained equipment can reduce operational downtime by up to 40%, significantly enhancing productivity. Regular maintenance practices not only extend the lifespan of equipment but also mitigate safety risks. Implementing scheduled inspections and adhering to manufacturer guidelines are fundamental aspects of a robust maintenance strategy. Moreover, keeping a detailed maintenance log can help in identifying patterns that may indicate deeper issues, thus allowing for timely interventions.

Safety in material handling environments is paramount, with the Occupational Safety and Health Administration (OSHA) reporting that improper equipment handling is a leading cause of workplace injuries. To promote safety, training staff on the proper use of equipment is essential. This includes understanding load limits, the importance of using personal protective equipment, and recognizing hazards. Furthermore, creating clear signage around equipment can serve as constant reminders of safety protocols.

Tips:

1. Incorporate regular training sessions for employees to ensure they are up to date with the latest safety practices and equipment usage.

2. Establish a maintenance calendar that highlights when inspections and servicing should be carried out to prevent unexpected equipment failures.

3. Use color-coded tags or labels on equipment to indicate maintenance status and safety compliance, enhancing visibility and awareness in the warehouse environment.

Related Posts

-

2025 Top Filling Machine Innovations Enhancing Efficiency and Precision in Manufacturing

-

10 Best Industrial Packaging Equipment for Maximum Efficiency

-

Revolutionizing Supply Chains: The Future of Industrial Packaging Equipment Explained

-

2025 How to Choose the Best Automatic Packaging Machines for Your Business

-

Transform Your Workspace: The Ultimate Guide to Selecting the Perfect Material Handling Carts

-

10 Best Custom Packaging Machines for Your Business Needs