How to Choose the Right Automated Packaging Equipment for Your Business?

Choosing the right automated packaging equipment can be daunting. The options are numerous and the decisions critical. "An optimal packaging line can transform productivity," says John Smith, a leading expert in automated packaging solutions. He emphasizes that selecting the right equipment is not just about technology; it's about aligning with business needs.

Investing in automated packaging equipment requires careful evaluation. Businesses must consider factors like product type, production speed, and budget constraints. Every detail matters. A small mistake in this choice can lead to inefficiencies and increased costs. It's not just about purchasing; it’s about integrating with existing processes.

Moreover, many companies rush into decisions without comprehensive research. They often overlook the importance of future scalability. Solutions that may seem sufficient now could quickly become obsolete. Reflection on these aspects can guide a smarter purchase. The right automated packaging equipment will not only maximize output but also improve overall operational efficiency.

Understanding Your Business Needs for Automated Packaging

Choosing the right automated packaging equipment begins with a clear understanding of your business needs. Consider your product type and volume. Different products require different packaging methods. Are you dealing with fragile items, liquids, or bulk goods? Each category has unique requirements that dictate equipment selection.

Evaluate your production speed. If your business is growing, you need equipment that can scale with your demands. It’s essential to discuss future growth with your team. Sometimes, companies underestimate growth projections. This can lead to overworked machines and delays.

Think about the space available in your facility. Compact equipment fits snugly where needed. However, it might not offer optimal performance. Room to maneuver is crucial for operator safety and efficiency. Don't rush this decision; a small miscalculation can create stress down the line.

Evaluating Different Types of Automated Packaging Equipment

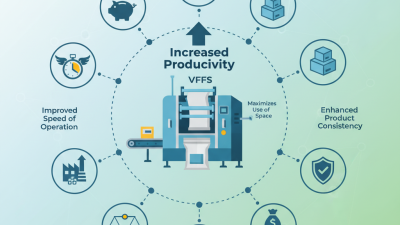

Choosing the right automated packaging equipment is crucial for efficiency. Various types exist, each serving different functions. Consider case sealers, labelers, and stretch wrappers.

Case sealers are great for securing boxes quickly. Labelers automate product identification and branding. Stretch wrappers are key for securing loads on pallets. Each type has unique strengths.

Think about your specific needs. Volume, product size, and packaging materials are essential factors. For example, high-volume businesses may require faster machines. Smaller operations might benefit from tabletop equipment. Sometimes, investing in a more versatile machine pays off. However, it’s important to avoid over-complicating processes. Over-engineered solutions can lead to confusion and inefficiency.

Evaluate your space and workflow. Size limitations may restrict equipment options. A well-organized layout can improve productivity. Additionally, consider maintenance needs. Some machines require more frequent servicing. A reliable, low-maintenance unit can save money long-term. Be mindful of staff training as well. Equipment that is easy to use minimizes errors and boosts efficiency.

Key Features to Look for in Packaging Machinery

When selecting automated packaging equipment, focus on the key features that matter most. Efficiency plays a crucial role in productivity. According to a recent industry report, businesses can boost output by 25% with the right machinery. Look for systems that offer high speed and adaptability. Machines with quick changeover capabilities can minimize downtime.

Consider user-friendly interfaces. Equipment should be easy for staff to operate. Training time can be reduced, allowing your team to focus on production. A study from the Packaging Machinery Manufacturers Institute indicated that user-centric designs lead to a 15% reduction in operational errors. Compatibility with existing processes is also essential.

Durability cannot be overlooked. Equipment must withstand heavy use and varied environments. Regular maintenance schedules are vital to ensure long-term performance. A strong warranty can show a manufacturer’s confidence in their product, yet it’s critical to read the fine print. Often, equipment that appears cost-effective may lead to higher costs due to repairs or replacements. The choice of materials used in machinery also influences longevity and hygiene in packaging.

Assessing Your Budget and ROI for Packaging Solutions

When choosing automated packaging equipment, assessing your budget is crucial. A clear understanding of your financial resources can help narrow down options. Look at both initial costs and ongoing maintenance fees. Equipment can vary significantly in price. You want to avoid overspending on features you may not need.

ROI is another essential factor. Consider how the equipment will improve efficiency and reduce labor costs. Calculate potential savings over time. It may be tempting to go for the cheapest option, but that could lead to higher costs in the long run. Think about reliability and longevity, as these can impact overall returns.

Keep track of hidden expenses too. Sometimes, installation and training costs are overlooked. They can add up quickly. Reflect on these aspects before making a decision. Your choice should align with both current needs and future growth.

Future-Proofing Your Investment in Packaging Technology

Investing in automated packaging equipment is more than just a purchase. It's a commitment to future-proofing your operations. In today's fast-paced market, adaptability is crucial. Studies show that 61% of companies are looking to upgrade their packaging technology within the next few years. Choosing the right equipment translates to a competitive edge.

One key consideration is scalability. Your business may grow. The equipment should accommodate increased production without significant investment. Reports indicate that flexible systems reduce downtime by 30%. A machine that can adapt to various product types will also be valuable. However, it’s easy to get overwhelmed. Evaluating available options can lead to indecision.

Another aspect is integration. New technologies must sync with existing systems. Research shows that nearly 70% of packaging failures tie back to integration issues. Therefore, a comprehensive assessment of your current setup is essential. Choosing equipment that aligns with your long-term strategy minimizes obsolescence. It's a balancing act between immediate needs and future growth. Investing in technology means considering your operational vision today and tomorrow.

Related Posts

-

Revolutionizing Efficiency: How Automated Packaging Machines Transform Your Production Line

-

Top 10 Packaging Automation Equipment for Streamlining Your Production Process

-

Top Packaging Equipment Trends You Need to Know for Your Business

-

10 Best Industrial Packaging Equipment for Maximum Efficiency

-

Top 10 Benefits of Using a Vertical Form Fill Seal Machine for Your Business

-

How to Choose the Right Food Packaging Machine for Your Business Needs