How to Choose the Right Food Packaging Machine for Your Business Needs

In today's fast-paced food industry, selecting the appropriate food packaging machine can significantly influence the success of a business. According to John Smith, a leading expert in food packaging technology, "The right packaging machine not only ensures product safety but also enhances branding and efficiency." With the multitude of options available in the market, it becomes imperative for businesses to understand their unique needs and the capabilities of various machines.

Food packaging machines come in different types, each designed to cater to specific requirements such as automation level, packaging material, and production volume. Therefore, business owners must conduct thorough research to identify the machine that aligns with their operational goals. Considerations such as the type of food products, shelf life, and packaging aesthetics play critical roles in making an informed decision.

Finding the right food packaging machine can lead to improved operational workflow, reduced downtime, and enhanced consumer satisfaction. As the industry continues to evolve, understanding the nuances of each packaging solution will empower businesses to make choices that not only meet regulatory standards but also resonate with their target audience.

Understanding Different Types of Food Packaging Machines

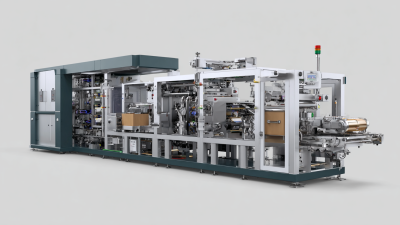

When selecting the right food packaging machine for your business, understanding the different types available is crucial. The market offers a variety of machines, including vertical form-fill-seal (VFFS), horizontal form-fill-seal (HFFS), and vacuum packaging machines. According to a recent industry report from Markets and Markets, the global food packaging machinery market is projected to reach $41.45 billion by 2025, driven by the increasing demand for processed and packaged foods. Each type of machine serves distinct purposes; for instance, VFFS machines are ideal for granulated products like rice or sugar, while HFFS machines are better for flexible packaging solutions.

Tips: Always assess your production needs before purchasing a machine. Consider factors such as the types of products you plan to package, desired speed, and shelf-life requirements. Additionally, evaluate the space available in your facility, as some machines have larger footprints than others.

Moreover, automation is increasingly becoming a priority in food packaging. Advanced machines incorporate features like automatic bagging and labeling, which can significantly enhance efficiency and reduce labor costs. According to another study by Grand View Research, the automated food packaging machine market is expected to grow at a CAGR of 4.9% from 2021 to 2028, illustrating the shift toward more tech-driven solutions. Understanding these trends can help you make a more informed decision when investing in packaging technology that aligns with your business goals.

Tips: Research the long-term costs associated with different machines, including maintenance and operational expenses, to ensure a sustainable investment.

Food Packaging Machine Types and Their Popularity

Assessing Your Business Requirements for Packaging

When selecting a food packaging machine, the first and most crucial step is to assess your specific business requirements. This involves evaluating the type of food products you deal with, their sizes, and the suitable packaging format. For instance, if your business focuses on perishable goods, you might require a machine that offers extended shelf-life packaging options. Additionally, understanding the volume of production plays a significant role; high-output demands may necessitate advanced machinery with faster packaging speeds, while smaller operations might benefit from more compact and versatile machines.

Another important factor to consider is the type of packaging materials you intend to use. Different machines cater to various materials, such as plastic, cardboard, or biodegradable options. Analyzing your commitment to sustainability can influence your choice, as many businesses are shifting towards eco-friendly materials. Furthermore, consider the future scalability of your operation; opting for a machine that can adapt or expand its capabilities will be beneficial as your business grows. Taking the time to thoroughly assess these requirements will lead to more informed and effective decisions, ultimately enhancing your production efficiency and product quality.

Evaluating Key Features of Packaging Machines

When selecting a food packaging machine, it's essential to evaluate key features that align with your business needs. According to market research by Grand View Research, the global food packaging machinery market size is expected to reach $50.38 billion by 2025, illustrating the increasing importance of effective packaging solutions. Key features to consider include the type of packaging (e.g., flexible vs. rigid), machine speed, and production capacity. Machines that can handle various packaging formats can provide greater flexibility, catering to dynamic market demands and reducing downtime when switching between different products.

Another critical consideration is automation level. A report by MarketsandMarkets indicates that automated packaging machinery can reduce labor costs by up to 30% while increasing efficiency. Companies should assess whether they need fully automated lines or semi-automated systems, depending on their scale and workforce capabilities. It's also important to evaluate ease of use and maintenance, as user-friendly interfaces and reliable service support can impact long-term operational efficiency.

Tips for choosing the right machine include conducting a thorough cost-benefit analysis that considers not only the initial investment but also potential savings in labor and waste reduction. Additionally, consult with suppliers or industry experts to ensure the selected machine meets your specific regulatory requirements, especially regarding food safety standards. Investing time in evaluating these features will ultimately lead to a more suitable packaging solution that enhances product preservation and visual appeal.

Comparing Costs and Budget Considerations

When choosing a food packaging machine for your business, understanding the costs and budget considerations is crucial. According to a report by Research and Markets, the global food packaging machinery market is projected to reach $45 billion by 2028, driven by innovations and consumer demands for efficient packaging solutions. However, determining the right machine involves more than just analyzing initial costs. Long-term budgets must account for maintenance, operating expenses, and potential upgrades as your business evolves.

Investing in a machine that fits your operational needs can yield substantial savings over time. For instance, semi-automated machines generally offer lower upfront costs but may require more labor, while fully automated systems, though pricier, can significantly boost productivity and reduce manual labor costs. According to a study by Grand View Research, businesses can expect a 30-50% increase in efficiency through automation. Evaluating the total cost of ownership, rather than the initial price alone, will help you make a more informed decision regarding your budget.

**Tips:**

1. Consider the scalability of the packaging machine to align with your future business growth.

2. Look for machines that offer energy-efficient options to decrease operational costs.

3. Always factor in potential packaging material costs as they can significantly impact your overall budget.

How to Choose the Right Food Packaging Machine for Your Business Needs - Comparing Costs and Budget Considerations

| Machine Type | Average Cost (USD) | Maintenance Cost (Annual) | Production Speed (items/min) | Suitable for |

|---|---|---|---|---|

| Vertical Form Fill Seal | $25,000 | $1,500 | 50 | Snacks, Powders |

| Horizontal Flow Wrapper | $30,000 | $2,000 | 70 | Bakery, Confectionery |

| Pallet Wrapper | $15,000 | $800 | N/A | Bulk Products |

| Shrink Wrap Machine | $20,000 | $1,200 | 40 | Beverages, Cans |

| Cartoning Machine | $50,000 | $3,000 | 80 | Frozen Foods, Packaged Goods |

Researching Manufacturers and Supplier Options

When it comes to selecting the right food packaging machine, researching manufacturers and supplier options is a critical step. Begin by identifying potential manufacturers who specialize in food packaging machinery. It's essential to compare their offerings, such as the types of machines available, customization options, and the technology they employ.

Look for manufacturers who have a proven track record in producing reliable and efficient machines that cater specifically to the food industry.

Once you have a list of potential suppliers, delve deeper into their reputations by reading customer reviews and testimonials. Engaging with other businesses in your industry can also provide valuable insights into their experiences with various manufacturers. This peer feedback can highlight key strengths or weaknesses in specific machinery, helping you make an informed choice. Additionally, consider reaching out to suppliers directly to inquire about their support services, warranty policies, and availability of parts for maintenance. This proactive approach will ensure that you select a manufacturer whose offerings align with your business's operational needs and long-term goals.

Related Posts

-

2025 Top 5 Food Packaging Machines Transforming the Industry

-

Top 10 Packaging Automation Equipment for Streamlining Your Production Process

-

Why Your Business Needs an Industrial Packing Machine for Efficiency and Growth

-

Revolutionizing Efficiency: How Automated Packaging Machines Transform Your Production Line

-

10 Best Custom Packaging Machines for Your Business Needs

-

Top 10 Custom Packaging Machines to Boost Your Business Efficiency in 2023