2026 How to Choose the Right Types of Packaging Machines for Your Business?

Choosing the right types of packaging machines is crucial for any business looking to enhance efficiency and maintain quality. According to packaging industry expert John Smith, "The right packaging machinery can transform your production line and save time." In today’s fast-paced market, a business must assess its specific needs before making a decision.

Different types of packaging machines cater to various products and industries. For instance, some machines are designed for liquids while others focus on solids. The choice can significantly impact productivity and costs. It's not just about automation; it’s about finding the right fit for your product type. Often, businesses overlook the importance of scalability. A machine that works today may not meet future demands.

Moreover, many companies underestimate the learning curve attached to new machinery. Operators may need training to maximize efficiency. Businesses must also consider maintenance and support options. A machine may seem perfect, but if parts are hard to replace, the long-term costs could rise. Understanding the types of packaging machines and their capabilities can lead to more thoughtful decisions and ultimately better business outcomes.

Understanding the Different Types of Packaging Machines Available

When selecting packaging machines, it’s crucial to understand the various types available. Each machine serves a unique purpose, designed for different products. For instance, vertical form-fill-seal machines are great for snacks. They ensure speed and accuracy, handling up to 200 bags per minute, according to industry reports. This type of machine maximizes efficiency and is ideal for bulk production.

Another popular choice is the labeling machine. Reports indicate that proper labeling increases consumer trust. An efficient labeling machine can apply up to 1000 labels per hour. This is essential for compliance in food and beverage sectors. However, improper setup can lead to mislabeling, costing businesses time and resources.

In addition, flow wrappers offer flexibility for packaging various products. They provide excellent protection and freshness, which attracts consumers. Yet, many companies overlook the importance of selecting the right film material. The wrong choice can compromise product integrity. Businesses need to carefully assess their needs before committing to a packaging solution, even after thorough research.

Assessing Your Business Needs for Packaging Solutions

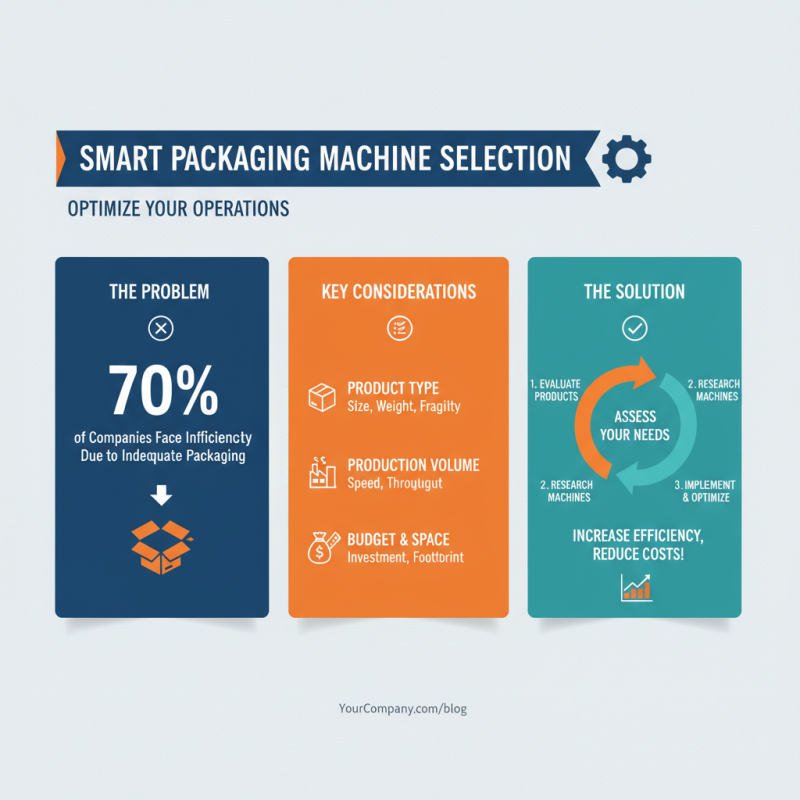

When considering the right packaging machines for your business, assessing specific needs is crucial. According to industry reports, 70% of companies experience inefficiencies due to inadequate packaging solutions. Every product has unique demands. Factors like size, weight, and fragility must be evaluated closely, as they impact machine selection dramatically.

More than just selecting a machine, understanding production volume is vital. A business packaging 500 units a day requires different machinery than one handling 5,000. Data shows that companies with tailored solutions report 30% higher productivity. Yet, even with the best plans, unforeseen challenges can arise. Equipment may not always meet expectations, leading to additional costs and time delays.

Innovative features might appear appealing. However, assessing return on investment should be prioritized. A flashy machine doesn't guarantee efficiency. Reports indicate up to 25% of businesses regret their equipment choices within a year. It's essential to align packaging solutions with long-term goals while remaining adaptable to changing market demands.

Evaluating Key Features of Packaging Machines

When choosing packaging machines, understanding key features is essential. You need to evaluate the type of products you are packing. Look for machines that match the size and weight of your items. Some machines work best for liquids, while others are suited for solids or powders. Tailoring your choice helps optimize efficiency.

Automation is another important aspect. A fully automated line can save time and labor costs. However, initial setup may require significant resources. Assess whether your production volume justifies this investment. Also, consider maintenance needs. Some machines might seem ideal but can become a burden without reliable support.

Don’t forget about flexibility. Your business may grow or shift focus. Choose machines that can adapt to different packaging styles. For example, a machine that handles various materials provides room for change. Engage with your team to gather input on these features. Their hands-on experience can guide you toward a more suitable solution.

2026 Packaging Machine Features Evaluation

This chart evaluates the key features of different packaging machines based on speed, flexibility, ease of use, maintenance frequency, and cost. It provides a comparative analysis to help you choose the right packaging machine for your business.

Comparing Costs and Budget Considerations for Packaging Equipment

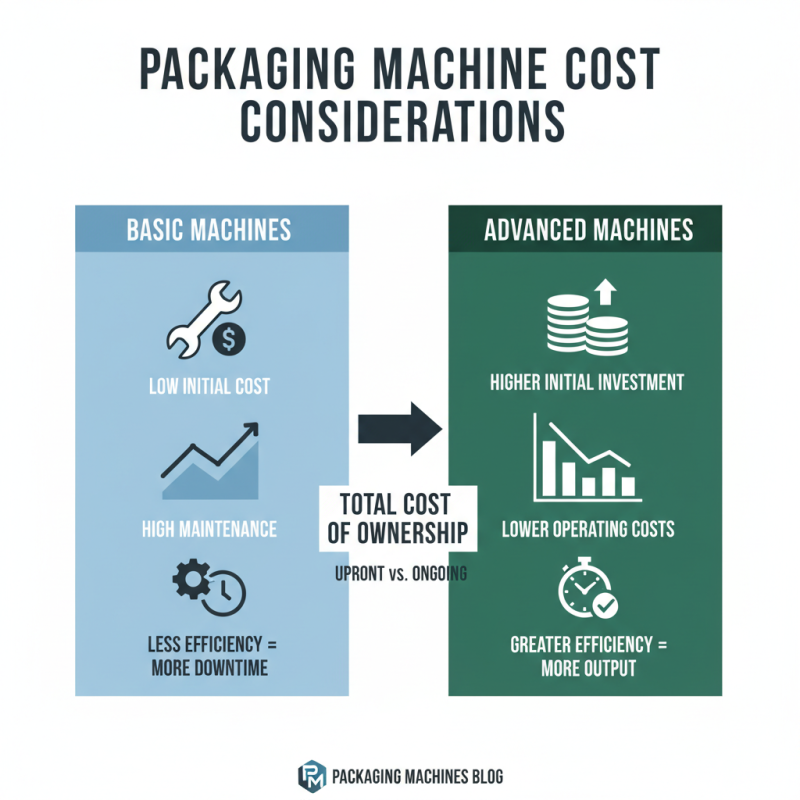

When selecting packaging machines, cost plays a critical role. The initial investment can vary greatly. Basic machines might seem cheap, but they could lead to high maintenance costs. Advanced machines often come with better efficiency but require a larger budget. It’s essential to assess both upfront and ongoing expenses.

Tips: Always factor in maintenance costs early. Basic models might save money upfront but can be more expensive in the long run. Research industry averages for potential costs.

Understanding your budget also involves considering space and personnel. A larger machine might need more room and could require extra operators. It’s crucial to calculate total costs, including installation and training. Don’t forget to include potential upscaling costs in your plans.

Tips: Analyze your workspace before making a decision. A small area could limit your options. Create a budget that incorporates all variables, not just equipment price. Revisit your budget frequently to ensure it aligns with your actual needs.

Exploring Maintenance and Support Options for Packaging Machines

Maintenance and support options for packaging machines are vital considerations for any business. Regular maintenance helps avoid breakdowns. It’s crucial to have a planned maintenance schedule. This schedule keeps machines running efficiently. A well-maintained machine improves output and quality. Unexpected downtime can severely affect productivity.

Consider the types of support available. Some machines come with comprehensive service contracts. These contracts can cover parts and labor. However, not all businesses require extensive support. A smaller operation might manage with basic technical assistance. Having access to knowledgeable technicians is important. They can provide quick solutions to problems as they arise.

Evaluate the cost of maintenance versus the benefits. Investing in appropriate support can save money in the long run. Businesses should also consider training staff on operating machines efficiently. Proper training reduces wear and tear. While some companies offer exemplary support, others may fall short. It’s essential to research and find the right fit.

2026 How to Choose the Right Types of Packaging Machines for Your Business? - Exploring Maintenance and Support Options for Packaging Machines

| Machine Type | Best For | Maintenance Frequency | Support Options | Approximate Cost |

|---|---|---|---|---|

| Vertical Form Fill Seal | Snacks, Granules | Weekly | On-site, Remote | $15,000 - $50,000 |

| Horizontal Flow Wrapper | Confectionery, Bakery | Monthly | Telephonic, Online | $25,000 - $70,000 |

| Bottle Filling Machine | Liquids | Quarterly | On-site, Remote | $30,000 - $80,000 |

| Pouch Packing Machine | Powders, Granules | Bi-annual | Online, Tutorials | $10,000 - $40,000 |

| Case Packing Machine | Bottles, Boxes | Annually | On-site, Remote | $40,000 - $100,000 |

Related Posts

-

How to Choose the Right Food Packaging Machine for Your Business Needs

-

Why Your Business Needs an Industrial Packing Machine for Efficiency and Growth

-

Revolutionizing Efficiency: How Automated Packaging Machines Transform Your Production Line

-

10 Best Custom Packaging Machines for Your Business Needs

-

Top 10 Packaging Automation Equipment for Streamlining Your Production Process

-

Top 5 Custom Packaging Machine Trends Driving Efficiency and Growth in 2023