What is a Conveyor System? Types, Uses, and Benefits Explained

Conveyor systems are an integral part of modern industries, facilitating the efficient movement of materials and products across various production lines and storage areas. These systems come in various types, each designed to serve specific functions and meet the unique demands of different applications. From manufacturing and warehousing to food processing and packaging, the versatility of conveyor systems enhances productivity by streamlining operations and reducing manual handling.

The benefits of implementing conveyor systems extend beyond just transportation. They help minimize labor costs, reduce the risk of workplace injuries, and increase overall operational efficiency. By understanding the different types of conveyor systems available, businesses can select the solutions that best suit their needs, ensure optimal performance, and maintain a smooth workflow. This article will delve deeper into the various types, uses, and benefits of conveyor systems, highlighting their critical role in the modern industrial landscape.

What is a Conveyor System?

A conveyor system is a mechanical apparatus designed to transport materials or products from one point to another within a facility. These systems are widely utilized in various industries, including manufacturing, warehouses, and distribution centers, due to their efficiency in handling bulk materials or high volumes of products. Typically comprising a series of belts, rollers, or chains, conveyor systems enable smooth and continuous movement, reducing manual labor and enhancing productivity.

When considering the implementation of a conveyor system, it’s essential to assess the specific needs of your operation. Factors such as load type, weight, and the distances involved play crucial roles in selecting the most suitable conveyor type. Additionally, integration with existing equipment and the system's ability to handle unique operational conditions should not be overlooked.

Tips: Ensure to conduct regular maintenance checks on your conveyor system to prevent unexpected downtimes. Implementing a preventive maintenance schedule can prolong the life of the system and ensure it operates at peak performance. Moreover, training employees on the proper usage and safety protocols related to conveyor systems is vital in minimizing workplace accidents and optimizing efficiency.

What is a Conveyor System? Types, Uses, and Benefits Explained

| Type of Conveyor | Description | Common Uses | Benefits |

|---|---|---|---|

| Belt Conveyor | A continuous loop of material used to transport items in various industries. | Mining, agriculture, manufacturing | High efficiency, low labor costs, reliable operation |

| Roller Conveyor | A series of rollers used to move materials, allowing for gravity-based transport. | Warehousing, packaging | Flexible, easy to install, scalable |

| Chain Conveyor | Utilizes chains to transport heavy loads and bulk materials. | Automotive, heavy manufacturing | Durable, capable of handling heavy objects, low maintenance |

| Magnetic Conveyor | Uses magnets to hold ferrous materials in place while moving. | Food industry, recycling | Safe for delicate products, reduces handling costs |

| Bucket Conveyor | Uses buckets attached to a belt or chain to transport bulk materials vertically. | Food processing, mining | Efficient vertical transport, minimizes spillage |

Types of Conveyor Systems and Their Applications

Conveyor systems are integral to various industries, enhancing efficiency and productivity. They come in different types, each tailored to meet specific operational needs. One common type is the belt conveyor, which utilizes a continuous loop of material, making it ideal for transporting bulk materials or goods across long distances. This system is widely used in manufacturing and logistics for its versatility and ease of maintenance.

Another popular type is the roller conveyor, often employed in warehouses and distribution centers. This system is designed for moving packages and pallets, allowing for manual or automated handling. The flexibility of roller conveyors makes them suitable for dynamic environments where goods need to be transported and sorted efficiently.

Additionally, modular conveyors provide customizable solutions, enabling businesses to create a layout that fits their unique operational flow, enhancing overall productivity while minimizing downtime. These various conveyor systems are essential tools in modern industry, each serving specific functions that contribute to streamlined processes and improved operational efficiency.

Key Components of Conveyor Systems Explained

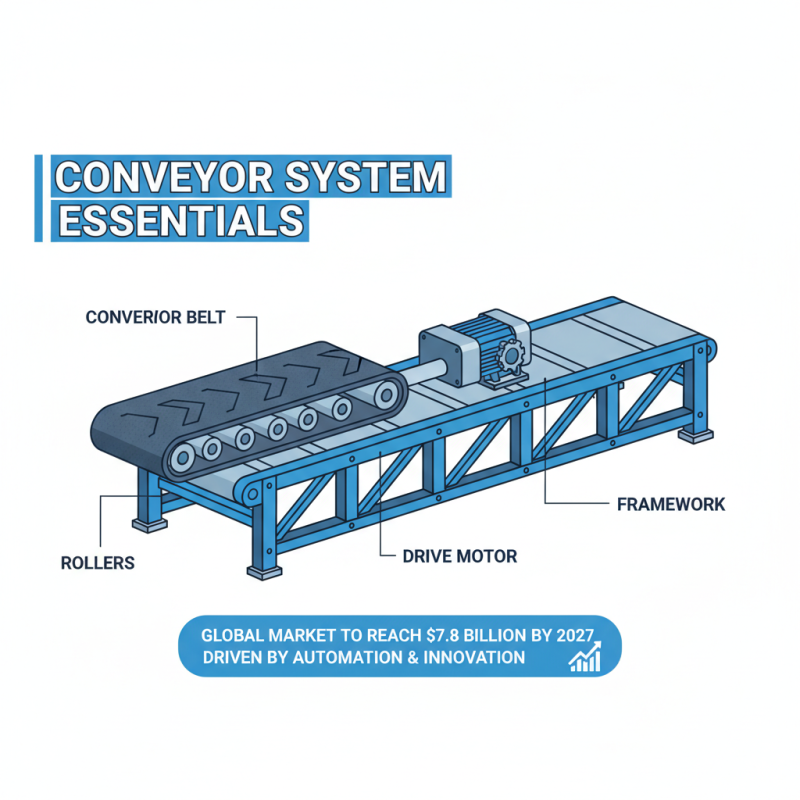

A conveyor system is a crucial component in many industrial operations, facilitating the efficient movement of materials and products throughout a facility. Understanding its key components is essential for optimizing productivity. The primary elements of a conveyor system include the conveyor belt, rollers, drive motor, and framework. The conveyor belt, which transports goods, can come in various materials such as rubber, plastic, or metal, depending on the specific needs of the operation. According to industry reports, the global conveyor systems market is expected to reach $7.8 billion by 2027, driven by innovations in automation and material handling processes.

The rollers, often found beneath the belt, play a vital role in supporting the load and reducing friction, enabling smoother operation. The drive motor powers the system, determining the speed and efficiency of material transport. Furthermore, the framework supports the entire structure, ensuring safety and stability. Proper maintenance of these components is crucial; a study indicates that regular inspections can enhance system longevity by up to 30%.

**Tip:** When designing a conveyor system, consider the type of materials being transported and their weight to choose appropriate belt and roller materials. Additionally, investing in quality motors can significantly improve energy efficiency, potentially reducing operational costs by a notable margin over time.

Benefits of Using Conveyor Systems in Various Industries

Conveyor systems are vital in various industries due to their ability to enhance productivity and streamline operations. One of the primary benefits of using these systems is their efficiency in transporting materials over long distances and complex paths. Whether in manufacturing, warehousing, or food processing, conveyor systems minimize manual handling, reducing labor costs and the risk of injuries associated with moving heavy items. This not only speeds up production but also ensures consistency in the flow of materials.

Another key advantage is the adaptability of conveyor systems to different environments and products. They can be designed to handle a wide array of materials, from fragile items like glass to bulk goods like gravel. This versatility allows businesses to optimize their workflows, making it easier to scale operations according to demand. Additionally, conveyor systems help in maintaining product quality by minimizing the chances of damage during transit.

Tips: When considering the implementation of a conveyor system, assess the layout of your workspace to maximize efficiency. Regular maintenance is crucial to ensure smooth operation and prolong the lifespan of the system. Lastly, training staff on the proper use of conveyor systems can further enhance safety and productivity in the workplace.

Maintenance and Safety Considerations for Conveyor Systems

Maintenance and safety are critical aspects of conveyor system operation. Regular inspections are essential to ensure that all components are functioning correctly and to identify any potential issues before they lead to serious problems. Routine maintenance tasks may include checking for wear and tear on belts, ensuring that pulleys and rollers are aligned, and lubricating moving parts to reduce friction. Keeping accurate maintenance records can help predict when parts may need to be replaced, thereby minimizing downtime and increasing the longevity of the system.

In addition to maintenance, safety considerations must be a priority in the workplace. Proper training for employees who operate or work near conveyor systems is vital to prevent accidents. Safety measures such as emergency stop buttons, guards to prevent contact with moving parts, and clear signage can help create a safer environment. Furthermore, implementing a comprehensive safety program that includes regular safety audits and employee feedback can enhance awareness and adherence to safety protocols, ultimately reducing the risk of accidents and injuries associated with conveyor systems.

Conveyor System Types and Their Usage Statistics

Related Posts

-

10 Essential Tips for Choosing the Right Automatic Bagging Machine

-

Innovative Material Handling Carts for Efficient Workplace Organization and Productivity

-

Top 10 Benefits of Using a Vertical Form Fill Seal Machine for Your Business

-

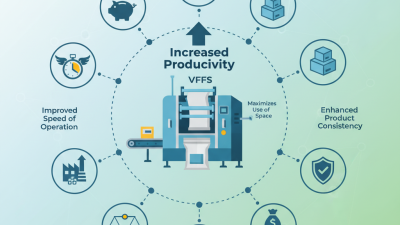

Mastering Efficiency: How VFFS Machines Revolutionize Packaging Processes for Modern Businesses

-

Top 10 Automated Packaging Machines You Need to Know About in 2023

-

Revolutionizing the Food Industry How Food Packaging Machines Enhance Freshness and Sustainability