What are Conveyor Systems and How Do They Work?

Conveyor systems are essential in modern industries. They simplify the movement of goods from one point to another. These systems save time and reduce labor costs effectively.

At their core, conveyor systems consist of belts, rollers, or chains. They transport products in a continuous loop. Different designs fit various applications, from manufacturing to logistics. However, improper setup or maintenance can lead to inefficiencies. Regular inspections are crucial for optimal performance.

Over time, these systems have evolved. Innovations in technology improve speed and reliability. Still, challenges remain. For example, understanding the specific needs of an operation is vital. Without this insight, even the best conveyor systems might underperform. The potential for improvement is always there, urging us to evaluate our choices continuously.

Understanding Conveyor Systems: Definition and Overview

Conveyor systems play a vital role in various industries, from manufacturing to logistics. They are mechanical devices that transport materials efficiently across a workspace. Understanding their function can lead to improved productivity. According to a report by Research and Markets, the global conveyor systems market is projected to reach $7.4 billion by 2025, indicating significant growth in automation.

These systems consist of belts, rollers, or chains. They move items over short or long distances. Commonly, conveyor belts are used to carry bulk materials. Automation reduces labor costs and increases safety. Yet, many companies struggle with maintenance. It's crucial to regularly inspect these systems to prevent downtimes. Ignoring small issues can lead to expensive repairs later on.

Tip: Implement a routine maintenance schedule. This approach keeps conveyor systems running smoothly. Additionally, train operators to identify early signs of wear and tear. Education often leads to better problem-solving. Adopting these practices can enhance operational efficiency significantly. Companies should always look for ways to innovate and improve their conveyor setups.

Types of Conveyor Systems: An Exploration of Various Designs

Conveyor systems play a crucial role in industries like manufacturing and logistics. Various designs exist to meet specific needs. Belt conveyors are among the most common types. They transport items over distances efficiently. According to a recent industry report, belt conveyors account for about 30% of the global market for conveyor systems. Their simplicity and effectiveness make them popular.

Roller conveyors are another type often used for heavy items. They are robust and durable. A study indicates that roller conveyors can handle loads up to 300 kg. However, the initial setup costs can be high. Companies must weigh long-term benefits against upfront investments. Modular conveyors also deserve mention. They offer flexibility and can be easily reconfigured. However, improper installation can lead to system inefficiencies.

Overhead conveyors are unique as they maximize floor space. They save room while transporting goods above work areas. Despite this, they can create accessibility challenges. Not every warehouse can adapt to overhead systems easily. Understanding these various designs can improve operational efficiency. Ultimately, the choice of a conveyor system depends on specific industrial needs. Each design has its advantages and drawbacks.

What are Conveyor Systems and How Do They Work? - Types of Conveyor Systems: An Exploration of Various Designs

| Type of Conveyor System | Description | Common Applications |

|---|---|---|

| Belt Conveyor | Uses a continuous belt to transport materials. | Mining, agriculture, manufacturing |

| Roller Conveyor | Transport products using rollers. | Warehousing, package handling |

| Chain Conveyor | Utilizes a chain to transport heavy materials. | Automotive, heavy industries |

| Screw Conveyor | Moves materials by means of a rotating screw. | Agriculture, food processing |

| Pneumatic Conveyor | Transport materials using air pressure. | Food industry, pharmaceuticals |

Key Components of Conveyor Systems: Machinery and Mechanisms Explained

Conveyor systems play a crucial role in various industries, providing efficient transport of goods. These systems consist of several key components that work seamlessly together. **Rollers** serve as the backbone, allowing items to glide smoothly. **Belts** provide a flexible surface for various load types. **Drives** enhance movement, ensuring consistent speed.

According to a report by the Conveyor Equipment Manufacturers Association (CEMA), the global conveyor system market is expected to grow significantly, reaching over $7 billion by 2026. This growth is driven by the demand for automation in manufacturing processes.

**Tip:** Regular maintenance of these components can prevent costly downtime. Inspect belts for wear and tear monthly. Ensure rollers are clean and free-moving to maintain efficiency.

The **pulleys** are essential as well, helping to change the direction of the belt. They can be a source of friction and must be monitored. An alarming statistic shows that nearly 40% of conveyor failures are pulley-related.

**Tip:** Implement a tracking system for your components. Doing so helps you spot issues before they escalate. A small investment in monitoring can save large repair costs in the future.

Conveyor System Components Usage

How Conveyor Systems Operate: Principles and Processes

Conveyor systems are vital in various industries, including manufacturing and logistics. Understanding how they operate is key to optimizing their efficiency. These systems utilize a combination of pulleys, belts, and rollers to transport materials. They operate on the principle of continuous movement, maintaining a steady flow of goods. A study from the International Conveyor Association indicates that 70% of material handling systems in warehouses incorporate conveyor technology.

The operation of conveyor systems involves several processes. Typically, materials are placed on the conveyor belt, which is driven by electric motors. Sensors can help detect blockages or malfunctions. According to industry reports, nearly 50% of unplanned downtime stems from equipment failure. Regular maintenance is crucial to prevent such issues. However, maintenance practices can sometimes be inconsistent, leading to inefficiencies.

While conveyor systems are efficient, they aren't without flaws. Systems can be slow to adapt to changes in demand. Overloading can lead to breakdowns and delays. Furthermore, employees must be trained to operate these systems properly, a step often overlooked. A report shows that proper training can reduce accidents by 30%. Investing in training and system upgrades can enhance overall performance and safety in operations.

Applications of Conveyor Systems: Industries and Use Cases

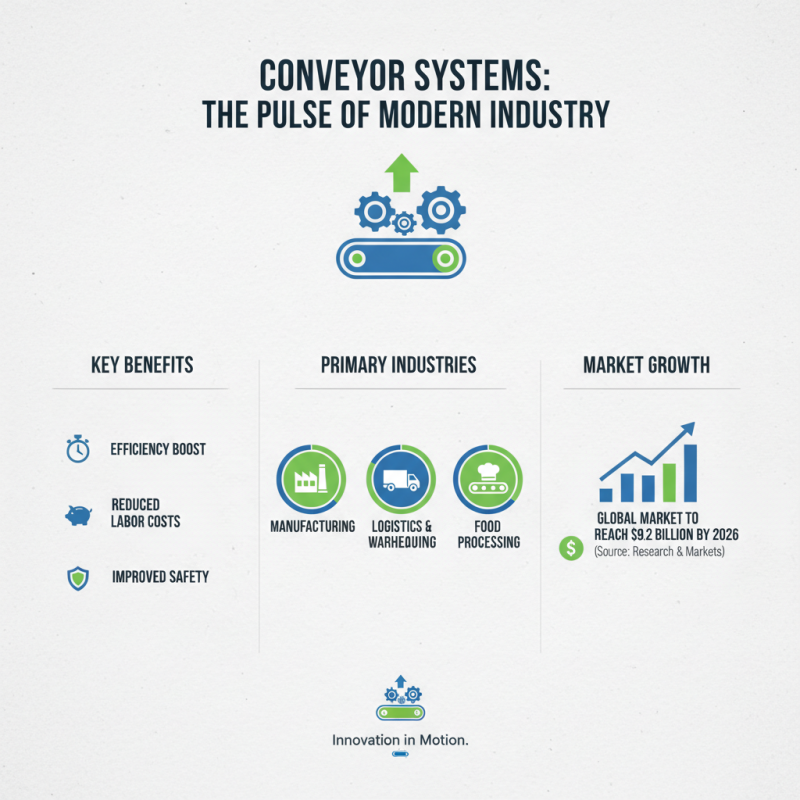

Conveyor systems play a vital role in various industries. They enhance efficiency, reduce labor costs, and improve safety. These systems are crucial in manufacturing, logistics, and even food processing. According to a report by Research and Markets, the global conveyor system market is expected to reach $9.2 billion by 2026, highlighting their growing importance.

In the manufacturing sector, conveyor systems transport materials and products seamlessly. From assembly line operations to warehousing, they minimize manual handling. The automotive industry particularly benefits from automated conveyor solutions. However, reliance on these systems can reveal weaknesses. Unexpected breakdowns may cause delays, leading to significant downtime and productivity loss.

The retail sector leverages conveyor systems for efficient order fulfillment. They aid in sorting and packing products, especially in large distribution centers. The COVID-19 pandemic accelerated the growth of e-commerce, putting pressure on supply chains. Analysis shows that efficient conveyor systems can reduce delivery times by up to 30%. Still, businesses must regularly evaluate their systems. Maintaining and upgrading conveyor technology can prevent obsolescence and ensure long-term success.

Related Posts

-

Exploring the Future of Conveyor Systems in Automation and Smart Manufacturing

-

How to Choose the Right Food Packaging Machine for Your Business Needs

-

Revolutionizing the Food Industry How Food Packaging Machines Enhance Freshness and Sustainability

-

Top Packaging Equipment Trends You Need to Know for Your Business

-

Top 10 Automated Packaging Machines You Need to Know About in 2023

-

What is a Food Packaging Machine and How Does It Enhance Product Freshness