What is a custom packaging machine and how does it work?

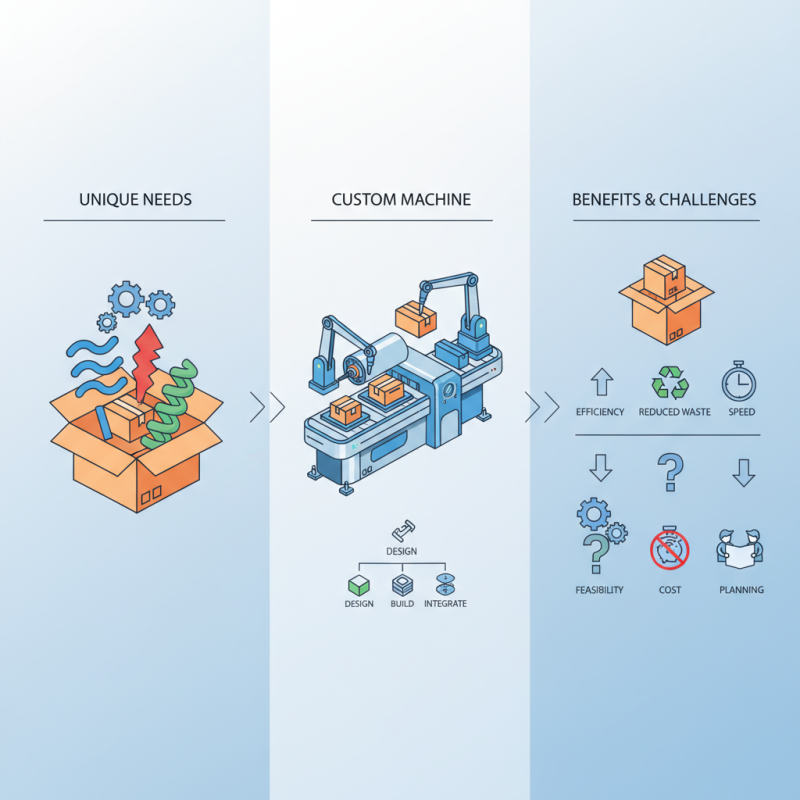

A custom packaging machine is a specialized tool designed to meet unique packaging needs. These machines create custom solutions tailored for various products. They streamline the packaging process, making it efficient and adaptable.

In the world of manufacturing, the significance of a custom packaging machine cannot be overlooked. For businesses, it means enhanced efficiency and reduced material waste. However, challenges exist. Not every design is feasible, and customization can be costly. It requires careful planning and creativity.

Understanding how a custom packaging machine works is essential for maximizing its benefits. These machines integrate advanced technology to deliver precision and speed. The right machine can revolutionize packaging, but poor choices can lead to operational issues. Engaging with experts can help navigate these complexities.

What is a Custom Packaging Machine? An Overview of Its Features

A custom packaging machine is designed to meet specific product needs. It can adapt to various sizes, shapes, and materials. This flexibility allows businesses to create unique packaging solutions, enhancing brand identity. Features often include adjustable components, user-friendly interfaces, and high-speed operation. These machines cater to different industries, from food to electronics.

The working principle of these machines is quite fascinating. They use sensors and automated systems to ensure precision. Products are fed into the machine, where they receive customized packaging. This might include wraps, boxes, or bags, depending on requirements. Many machines incorporate technology to minimize waste, though achieving perfect efficiency can be challenging. Users may encounter occasional technical issues, requiring adjustments.

Customization is a double-edged sword. While it enhances productivity, it can complicate operations. Operators need to be well-trained to maximize the machine's potential. Sometimes, setups may take longer than expected. Yet, the result often justifies the effort, offering a tailored solution that stands out in the market.

Custom Packaging Machines Usage Analysis

Key Components of Custom Packaging Machines and Their Functions

Custom packaging machines play a vital role in industries requiring tailored solutions. Understanding their key components helps illuminate their operation. One crucial element is the feed system. It ensures that materials are supplied consistently. A smooth feed minimizes downtime. Attention to detail in this area can significantly enhance efficiency.

Another important component is the forming system. It creates packages from raw materials. This might involve cutting, folding, or sealing. Precision is key here. A small misalignment can lead to waste. Operators need to regularly check the forming tools for wear and accuracy.

Additionally, the sealing system secures the package. It may use various methods, such as heat sealing or adhesive bonding. A reliable seal protects the product. However, achieving a perfect seal can be challenging. Variations in material can affect performance. Continuous monitoring can help address these issues effectively.

How Custom Packaging Machines Improve Efficiency in Production Lines

Custom packaging machines are essential in modern production lines. They enhance productivity by automating packing processes. This reduces manual labor, allowing workers to focus on other tasks. Custom machines adapt to different products. They accommodate various shapes and sizes effectively.

Efficiency is a significant advantage after implementing these machines. They minimize packaging errors that often lead to waste. Additionally, speed increases. A machine can work much faster than human hands. Mistakes are less frequent, but occasionally, they happen. It’s vital to monitor the machine closely.

Tips:

Regular maintenance keeps custom packaging machines running smoothly. Address any minor issues before they escalate. Always train staff to understand the machines. A knowledgeable operator can troubleshoot effectively. Also, evaluate the packaging materials. The right choice increases efficiency and reduces costs.

What is a custom packaging machine and how does it work? - How Custom Packaging Machines Improve Efficiency in Production Lines

| Dimension | Description | Impact on Efficiency |

|---|---|---|

| Speed | The rate at which a machine can package products. | Increased speed reduces production time and costs. |

| Flexibility | Ability to accommodate different packaging sizes and types. | Allows for quick changeovers between products, enhancing productivity. |

| Automation | Integration of automated processes in packaging operations. | Reduces manual labor, minimizing errors and increasing throughput. |

| Precision | Accuracy in packing weights and quantities. | Ensures compliance with regulations and reduces material waste. |

| Cost-effectiveness | Overall cost of the packaging process versus product output. | Lower costs per unit lead to better profit margins. |

Industry Applications: Where Custom Packaging Machines Are Utilized

Custom packaging machines play a crucial role across various industries. In food and beverage, these machines help package products efficiently. They ensure freshness and extend shelf life. For pharmaceuticals, precise packaging is essential. It guarantees dosage accuracy and prevents contamination. Additionally, cosmetic companies benefit from custom solutions that enhance product presentation.

In the e-commerce sector, custom machines streamline packaging processes. They can adapt to different product shapes and sizes. This flexibility can lead to reduced material waste. However, the initial investment in technology can be high. Some companies may struggle to justify the expense. Adjusting workflows to integrate these machines requires careful planning. In smaller operations, there could also be a learning curve for employees.

Consumer electronics is another field where custom packaging shines. It protects delicate devices during shipping. Yet, striking a balance between protection and sustainability is a challenge. Often, packaging ends up being excessively bulky. Companies must evaluate their environmental footprint while maintaining product safety. Addressing these issues can lead to long-term benefits.

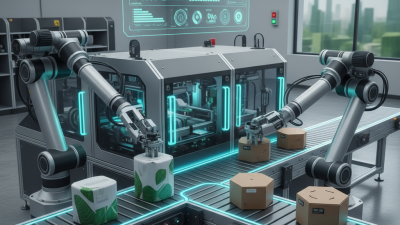

Understanding the Technology Behind Custom Packaging Machine Operations

Custom packaging machines are innovative tools designed to meet specific packaging needs. These machines can handle various materials like plastic, paper, and metal. They create tailored packaging solutions that fit products perfectly. Understanding the technology behind these machines reveals their sophistication and efficiency.

At the heart of custom packaging machines is advanced automation. Sensors monitor the packaging process, ensuring precision. The controls allow for quick adjustments based on product size. This flexibility is crucial for businesses with diverse product lines. However, machine calibration can be tricky. Small miscalculations may lead to waste or poor packaging quality.

These machines also incorporate software that streamlines operations. Users can program different packaging styles with ease. Yet, the learning curve for new users can be steep. Training is essential to minimize mistakes. Regular maintenance is also necessary to keep machines running smoothly. Skipping maintenance can affect performance. Thus, operators must remain vigilant.

Related Posts

-

Revolutionizing the Food Industry How Food Packaging Machines Enhance Freshness and Sustainability

-

Top 5 Custom Packaging Machine Trends Driving Efficiency and Growth in 2023

-

2025 How to Choose the Best Automatic Packaging Machines for Your Business

-

Top 10 Automated Packaging Machines You Need to Know About in 2023

-

10 Essential Tips for Choosing the Right Automatic Bagging Machine

-

10 Best Filling Machines for Efficient Packaging Solutions?