Top 5 Custom Packaging Machine Trends Driving Efficiency and Growth in 2023

In the fast-evolving landscape of manufacturing and distribution, the importance of leveraging advanced technology to enhance operational efficiency cannot be overstated. Custom packaging machines have emerged as a crucial component in this transformation, adapting to the unique requirements of various industries while streamlining production processes. As businesses strive to optimize their supply chains and reduce overhead costs, these machines offer tailored solutions that significantly improve accuracy, speed, and flexibility.

In 2023, several key trends are shaping the development and implementation of custom packaging machines, driving both efficiency and growth. From increased automation to the integration of smart technologies, these advancements are enabling companies to meet consumer demands while maintaining sustainability practices. By examining these trends, we gain insight into how custom packaging machines can not only enhance production capabilities but also foster innovation and adaptability in an increasingly competitive marketplace.

As organizations continue to prioritize customization and efficiency, understanding the trends surrounding custom packaging machines becomes imperative for those looking to stay ahead in the industry. Embracing these advancements can lead to sustainable growth and a more tailored approach to packaging solutions, ensuring businesses remain resilient in the face of changing market dynamics.

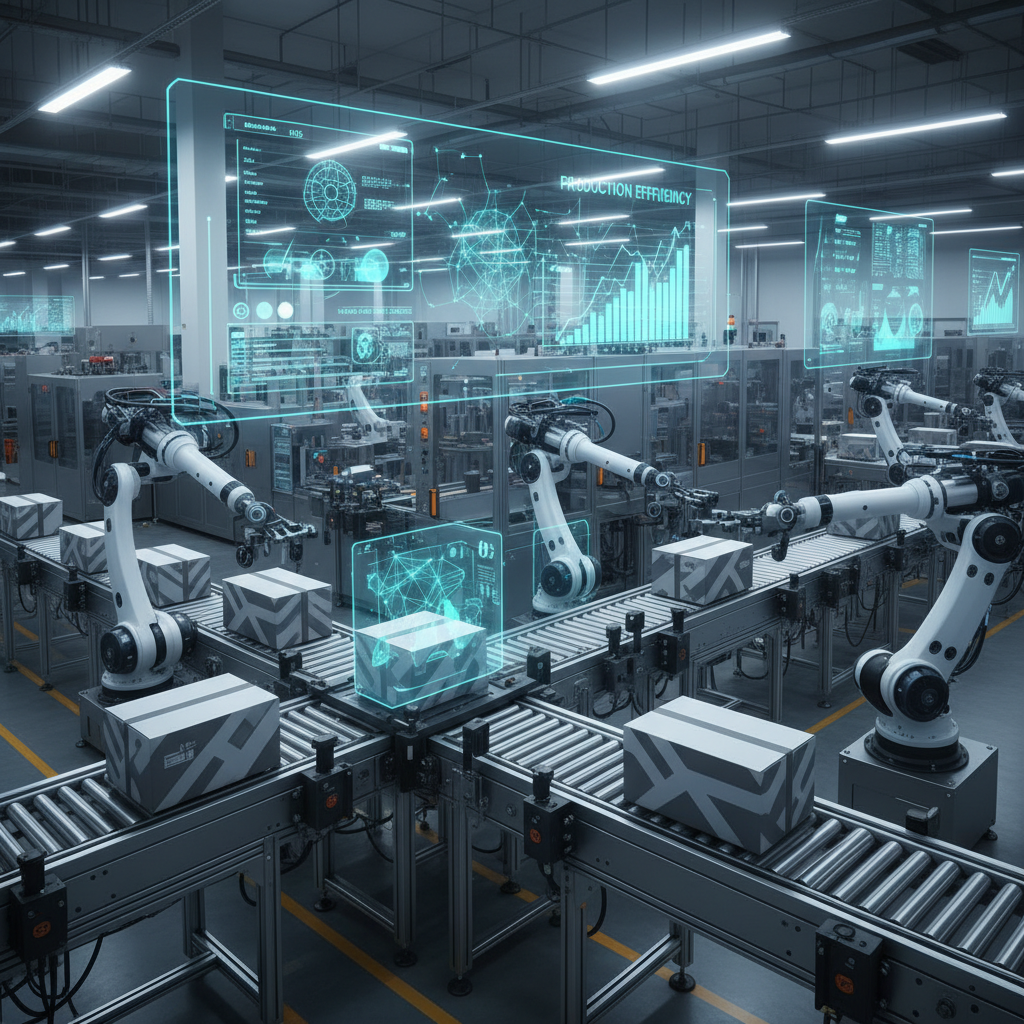

Emergence of AI-Driven Custom Packaging Solutions Enhancing Production Line Efficiency

The integration of artificial intelligence (AI) in custom packaging solutions is transforming the landscape of production line efficiency in 2023. According to a report by Smithers, the global smart packaging market is projected to reach $31.63 billion by 2027, reflecting a growing demand for automation and intelligent solutions within the packaging industry. These AI-driven systems optimize production by analyzing data in real time, which enhances decision-making and reduces downtime, ultimately increasing throughput and lowering operational costs.

Moreover, AI technologies, such as machine learning and computer vision, enable packaging machines to adapt to various product specifications with minimal human intervention. A recent survey by the Packaging Machinery Manufacturers Institute (PMMI) found that approximately 58% of manufacturers have already implemented some form of AI technology in their operations, noting a remarkable improvement in production rates by up to 30%. This trend highlights how AI-driven custom packaging is not just a technological advancement but a necessity for companies striving for efficiency and growth in an increasingly competitive market. As businesses continue to embrace these innovations, the potential for enhanced production and sustainability will shape the future of packaging.

Rise of Eco-Friendly Materials in Custom Packaging Supporting Sustainability Goals

In 2023, the packaging industry is witnessing a significant shift towards

eco-friendly materials that align with global sustainability goals. This trend is not merely a response to consumer demand for greener options, but a fundamental change in how brands approach their packaging strategies. Companies are increasingly adopting biodegradable, recyclable, and compostable materials to reduce their environmental footprint, reflecting a broader commitment to

corporate social responsibility.

The rise of eco-friendly materials in custom packaging also enhances

brand loyalty among environmentally conscious consumers. By choosing sustainable options, brands not only demonstrate their commitment to the planet but also differentiate themselves in a crowded marketplace. This strategic alignment with sustainability helps businesses attract and retain customers who prioritize

ethical consumption. As manufacturers innovate in this space, the potential for reducing waste and optimizing resource use becomes more pronounced, driving both efficiency and growth across various sectors in 2023.

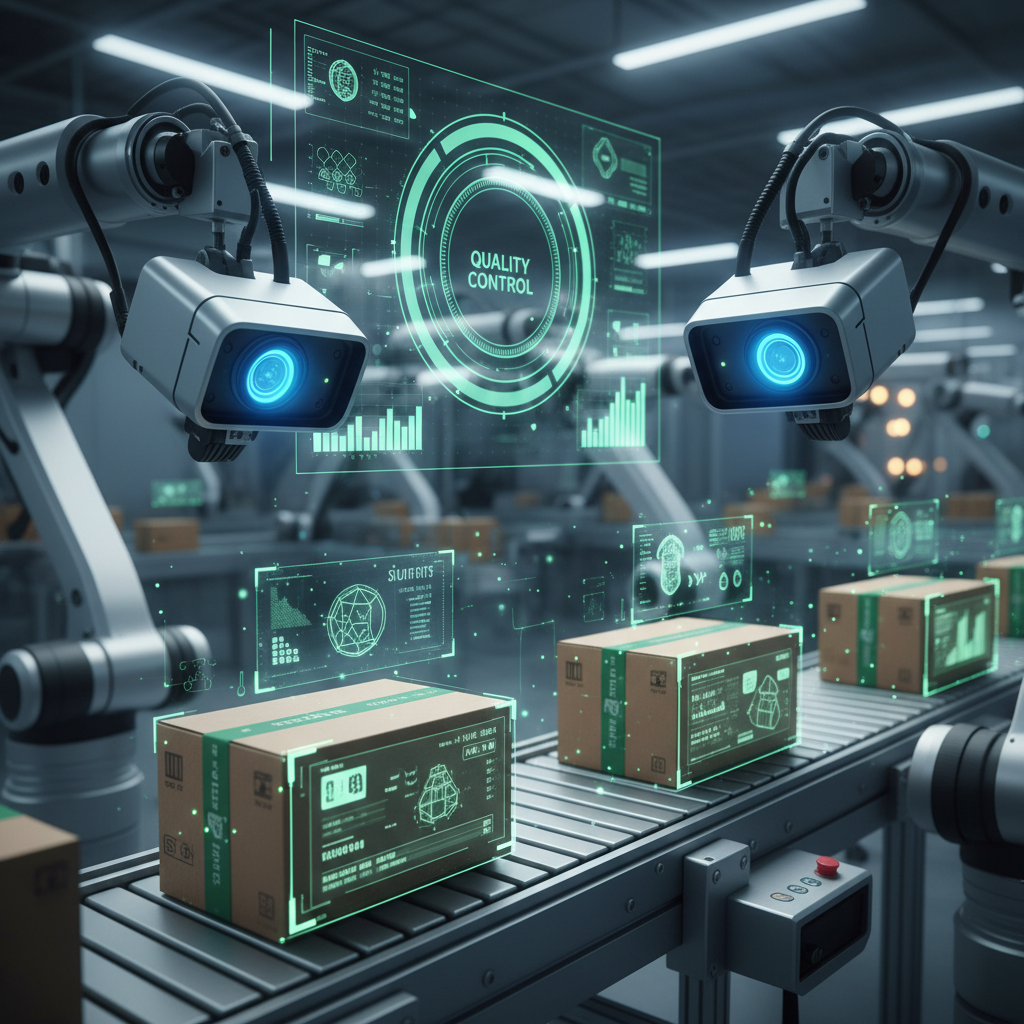

Integration of Smart Technology for Enhanced Tracking and Quality Control in Packaging

The integration of smart technology into packaging is revolutionizing the industry, especially in enhancing tracking and quality control. By leveraging AI-powered machine vision, manufacturers can now detect defects in real-time, significantly reducing waste and optimizing production processes. This approach not only improves product quality but also ensures compliance with safety standards, ultimately leading to enhanced consumer trust.

Moreover, smart packaging solutions are becoming increasingly crucial, as they enable the monitoring of product conditions throughout the supply chain. Technologies like surface-enhanced Raman scattering sensors embedded in packaging can actively sense and preserve food quality, extending shelf life and enhancing customer safety. As the demand for more efficient and reliable packaging solutions grows, the incorporation of these advanced technologies not only drives operational efficiency but also positions companies for sustained growth in a competitive market.

Customization Trends in Packaging Design Driving Consumer Engagement and Brand Loyalty

In 2023, customization trends in packaging design have emerged as a pivotal strategy for enhancing consumer engagement and fostering brand loyalty. According to a recent report by Smithers Pira, 72% of consumers express a stronger connection to brands that offer personalized packaging. This is a significant increase from previous years, highlighting the growing importance of tailored solutions in a crowded marketplace. Brands that incorporate unique designs, sustainable materials, and interactive elements in their packaging can create a memorable unboxing experience, further solidifying customer relationships.

**Tip:** To effectively engage consumers, consider incorporating QR codes on your packaging, leading to exclusive content or loyalty programs. This innovative approach not only enhances the customer experience but also provides valuable data insights into consumer behavior.

Furthermore, sustainability has become a cornerstone of modern packaging trends. According to a study by Nielsen, 66% of global consumers are willing to pay more for products from sustainable brands. By integrating eco-friendly packaging solutions, companies can resonate with environmentally conscious consumers and improve brand perception. Tailoring your brand’s packaging to reflect sustainability can capture attention and drive loyalty among an increasingly aware customer base.

**Tip:** If you are adopting sustainable materials, clearly communicate your efforts on the packaging itself. Transparent messaging about your commitment to sustainability can significantly impact purchasing decisions.

Top 5 Custom Packaging Machine Trends Driving Efficiency and Growth in 2023

Innovations in Automated Packaging Systems Reducing Labor Costs and Increasing Throughput

The landscape of packaging technology is evolving rapidly in 2023, with innovations in automated packaging systems leading the charge. These advanced systems are not only streamlining processes but also significantly reducing labor costs, making them vital for companies aiming for efficiency. Automation minimizes human error, enhances precision, and allows for 24/7 operations, which directly contributes to increased throughput. As businesses scale their operations, the ability to produce packaging solutions quickly and reliably becomes a competitive advantage.

When considering the implementation of automated packaging systems, it’s essential to assess your production needs carefully. **Tips:** Start by evaluating the current bottlenecks in your packaging process. Identifying areas where automation can have the most impact will help you prioritize investment and maximize returns. Additionally, ensure that your workforce is adequately trained to operate these technologies, promoting a smooth transition and greater effectiveness.

Investing in a custom packaging machine that can adapt to various product types is another key trend in 2023. This adaptability enhances operational flexibility, allowing businesses to respond swiftly to market changes and customer demands. **Tips:** Explore modular packaging solutions that can be easily reconfigured. This not only future-proofs your operations but can also lead to significant cost savings over time as production needs evolve.

Top 5 Custom Packaging Machine Trends Driving Efficiency and Growth in 2023

| Trend | Description | Impact on Efficiency | Growth Potential (%) |

|---|---|---|---|

| Increased Automation | Utilizing AI and robotics to automate packaging processes. | Reduces labor costs by up to 30%. | 20% |

| Eco-Friendly Materials | Adopting sustainable packaging solutions that minimize environmental impact. | Improves brand image while optimizing operational costs. | 15% |

| Smart Packaging Technologies | Integrating IoT devices for real-time monitoring and tracking. | Enhances inventory management leading to 25% faster fulfillment. | 30% |

| Customizable Packaging Solutions | Offering tailored solutions for diverse product requirements. | Increases customer satisfaction by allowing flexibility. | 18% |

| Enhanced Safety Features | Introducing advanced safety mechanisms in packaging machinery. | Reduces workplace accidents, thereby lowering insurance costs. | 10% |

Related Posts

-

Revolutionizing Efficiency: How Automated Packaging Machines Transform Your Production Line

-

10 Best Custom Packaging Machines for Your Business Needs

-

Top 10 Packaging Automation Equipment for Streamlining Your Production Process

-

2025 Top Filling Machine Innovations Enhancing Efficiency and Precision in Manufacturing

-

Top 10 Custom Packaging Machines to Boost Your Business Efficiency in 2023

-

10 Best Industrial Packaging Equipment for Maximum Efficiency