10 Essential Tips for Choosing the Right Automatic Bagging Machine

When it comes to enhancing operational efficiency in packaging processes, selecting the right automatic bagging machine is crucial for businesses across various industries. With advancements in technology, these machines have become essential tools for streamlining production, minimizing manual labor, and ensuring consistent quality in packaging. However, given the wide variety of options available, choosing the most suitable automatic bagging machine can be a daunting task.

In this guide, we will outline ten essential tips to help you navigate the selection process effectively. From considering the specific needs of your operation, such as the types of products being bagged and the desired speed of production, to evaluating the machine's features and compatibility with existing systems, these insights will empower you to make informed decisions. Additionally, understanding the importance of after-sales support and maintenance can contribute significantly to maximizing your investment in an automatic bagging machine. By carefully analyzing these factors, you can ensure that your choice aligns perfectly with your business goals and operational requirements.

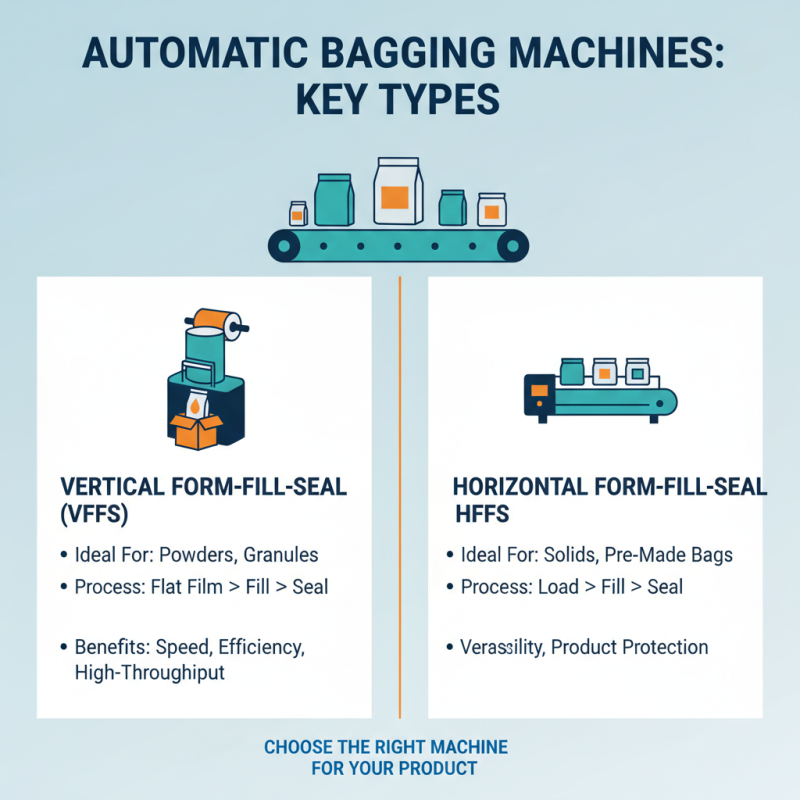

Understanding the Different Types of Automatic Bagging Machines

When selecting an automatic bagging machine, understanding the different types available is crucial. There are several models designed for specific applications, such as vertical form-fill-seal machines, which are ideal for packaging powders and granular products. These machines create bags from flat rolls of film, filling and sealing them simultaneously. They are known for their speed and efficiency, making them suitable for high-throughput environments.

Another type to consider is the horizontal form-fill-seal machine, often used for larger items like food products or industrial goods. This machine functions similarly but operates in a horizontal plane, allowing for a wider range of product sizes and shapes. Additionally, there are automatic bagging systems designed for specific materials like pre-made bags, which offer great flexibility in terms of bag design and material selection. Each type of machine has its unique strengths, so it’s essential to evaluate your specific packaging needs, product characteristics, and production capabilities before making a choice.

Evaluating Production Speed and Efficiency Requirements

When selecting the right automatic bagging machine, evaluating production speed and efficiency requirements is key to ensuring optimal performance in your packaging operations. First, consider the volume of products you need to bag within a specific timeframe. A machine that aligns with your production goals will help reduce bottlenecks and maintain a steady workflow. It is essential to analyze your current production rates and identify any potential growth in demand. This foresight will help you choose a machine that not only meets current needs but can also accommodate future increases in volume without sacrificing performance.

Next, assess the operational efficiency of the machine. Look for features that streamline the bagging process, such as automatic adjustments based on product size, quick changeover capabilities, and minimal downtime for maintenance. Pay attention to the machine's speed ratings, as some models may provide high throughput but require additional time for setup and adjustments. A balanced approach that prioritizes both speed and reliability will ultimately provide a more sustainable solution for your packaging line. By carefully evaluating these factors, you can ensure that your choice of an automatic bagging machine maximizes productivity and efficiency in your operations.

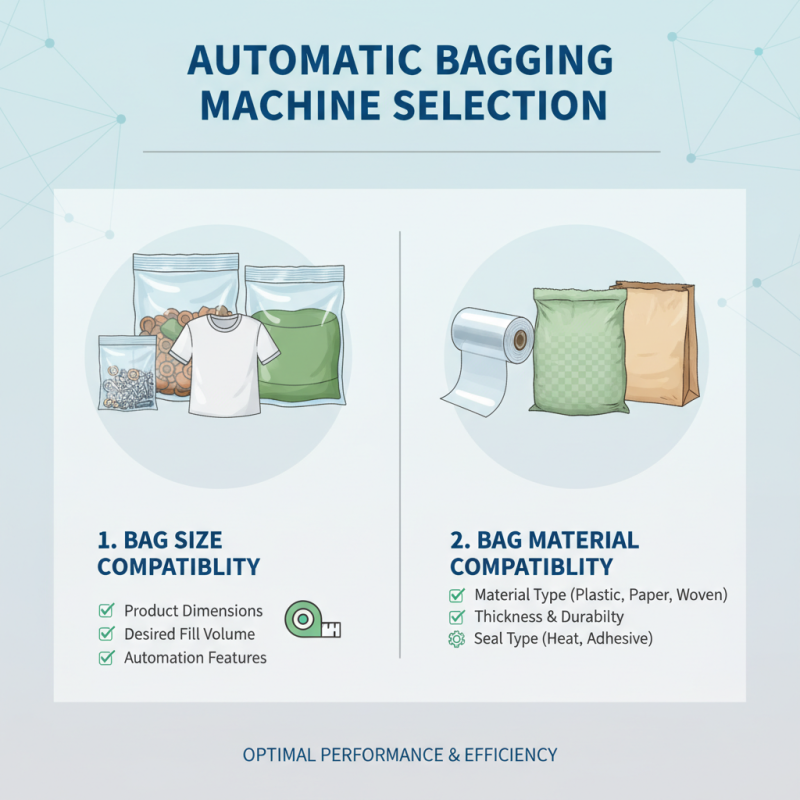

Assessing Bag Size and Material Compatibility

When selecting an automatic bagging machine, assessing bag size and material compatibility is crucial for ensuring optimal performance and efficiency. First, it’s important to determine the size of the bags you plan to use. Different machines are designed to accommodate specific bag dimensions, meaning choosing the right machine involves aligning its capabilities with your packaging requirements. Consider factors such as the dimensions of the products being packaged, the desired fill volume, and any automation features that might require specific bag sizes.

Material compatibility is equally important, as the bagging machine must be capable of handling various materials, whether they are plastic, paper, or biodegradable options. Each material behaves differently during the packaging process, influencing factors like sealing, durability, and ease of handling. Understanding the properties of the materials you intend to use will help you select a machine that not only meets your speed and efficiency needs but also maintains the integrity of the bags throughout the packaging cycle. Ensuring that both bag size and material are compatible with your chosen machine can significantly enhance productivity and reduce operational challenges.

Exploring Automation Features and Control Systems

When selecting the right automatic bagging machine, understanding the automation features and control systems is paramount for optimizing production efficiency.

According to a report by MarketsandMarkets, the global market for automatic bagging machines is projected to reach $4.23 billion by 2026, reflecting a growing trend towards automation in packaging processes.

A sophisticated control system allows for real-time monitoring and adjustments, improving accuracy and reducing waste, which is crucial in maximizing operational throughput.

Automation features such as programmable logic controllers (PLCs) and user-friendly interfaces enhance the usability of bagging systems.

These advanced control systems enable operators to set parameters quickly, facilitating rapid product changes and minimizing downtime.

Data from a recent study by PMMI indicates that manufacturers switching to automated bagging reported a 30% increase in production rates, showcasing the significant advantages of integrating automated controls.

With the right machine, businesses not only streamline their packaging processes but also ensure that they keep pace with the demands of an increasingly competitive market.

Considering Budget and Long-Term Maintenance Costs

When selecting an automatic bagging machine, understanding your budget and long-term maintenance costs is crucial. The initial purchase price of the machine is only one aspect; it’s essential to consider how much you’ll spend on maintaining and operating the equipment over time. This includes replacement parts, service fees, and unexpected repairs, which can add up quickly.

One key tip is to factor in the cost of consumables and spare parts when calculating your overall expenses. Look for machines that offer readily available parts and have a solid reputation for reliability and durability. This not only eases the maintenance process but also minimizes downtime, which can have a significant impact on productivity.

Another important consideration is the machine's energy efficiency and ease of use. Opt for models designed with energy-saving features that can lower utility costs, and ensure they are user-friendly to reduce training time and potential operator errors. An efficient machine will not only save you money in the long run but also enhance the overall efficiency of your packing operations.

Cost Analysis of Automatic Bagging Machines

This bar chart illustrates the estimated costs associated with different types of automatic bagging machines, focusing on initial investment and long-term maintenance costs. The data highlights the importance of considering both factors when making a purchasing decision.

Related Posts

-

2025 How to Choose the Best Automatic Packaging Machines for Your Business

-

Top 10 Automated Packaging Machines You Need to Know About in 2023

-

10 Best Industrial Packaging Equipment for Maximum Efficiency

-

Revolutionizing Supply Chains: The Future of Industrial Packaging Equipment Explained

-

Top 5 Custom Packaging Machine Trends Driving Efficiency and Growth in 2023

-

Top 10 Packaging Automation Equipment for Streamlining Your Production Process