What is a Food Packaging Machine and How Does It Enhance Product Freshness

In the fast-paced world of food production and distribution, maintaining product freshness is paramount. A food packaging machine plays a crucial role in this process, ensuring that perishable items are protected from environmental factors that can compromise their quality. By utilizing advanced packaging technology, these machines provide an effective barrier against moisture, oxygen, and contaminants, significantly extending the shelf life of food products.

The significance of a food packaging machine cannot be overstated, as it not only enhances the longevity of food items but also contributes to food safety. In an era where consumers are increasingly concerned about the quality and safety of their meals, the implementation of sophisticated packaging solutions allows manufacturers to meet these demands. Furthermore, the automation and efficiency provided by food packaging machines streamline production processes, reducing waste and improving overall operational effectiveness.

In this article, we will explore the various functions of food packaging machines and their impact on preserving freshness, ensuring that quality food products reach consumers while maintaining their intended taste, texture, and nutritional value. Through an in-depth examination, we will highlight why investing in modern food packaging technology is essential for food businesses aiming to thrive in a competitive marketplace.

What is a Food Packaging Machine: Definition and Purpose

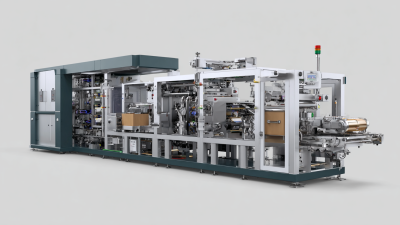

A food packaging machine is a specialized device designed to package food products in a manner that preserves their freshness, extends shelf life, and enhances safety for consumers. These machines utilize various methods including vacuum sealing, heat sealing, and modified atmosphere packaging to minimize exposure to air, moisture, and contaminants. By creating a protective barrier around the food, these machines play a crucial role in maintaining the quality and integrity of the products throughout their distribution and storage lifecycle.

The primary purpose of a food packaging machine is to ensure that food items remain fresh and safe for consumption for as long as possible. This is particularly important in a market where consumers demand high-quality and fresh products. Effective packaging not only prevents spoilage and contamination but also helps in preserving the nutritional value and flavor of the food. Additionally, packaging machines can enhance the efficiency of food processing operations, allowing for faster packaging and reduced labor costs, which ultimately benefits producers and retailers alike.

Impact of Food Packaging on Product Freshness

Types of Food Packaging Machines: An Overview of Common Varieties

Food packaging machines play a crucial role in the food industry by helping to maintain product freshness and extending shelf life. There are several types of food packaging machines, each tailored to specific packaging needs. Common varieties include vacuum sealers, which remove air from packages to inhibit oxidation and microbial growth; modified atmosphere packaging (MAP) machines that replace the atmosphere inside the package with a protective gas mixture; and heat sealers, which use heat to fuse materials together for secure sealing. According to a recent industry report, the global food packaging machinery market is projected to grow at a CAGR of 4.4% from 2021 to 2028, highlighting the increasing demand for efficient packaging solutions.

When selecting a food packaging machine, it's essential to consider the type of food being packaged. For instance, perishable items like meat may benefit most from vacuum packaging to prolong freshness, while dry goods like grains could utilize heat sealing for robust packaging.

**Tips:** Ensure that the selected packaging method aligns with the product's unique shelf-life requirements and distribution channels. Additionally, keep up with advancements in technology, as innovations in packaging can further enhance freshness while also improving sustainability. By investing in the right machinery, food businesses can significantly reduce waste and meet consumer demands for fresh, high-quality products.

How Food Packaging Machines Work: The Technology Behind Freshness

Food packaging machines play a crucial role in preserving the freshness of products through innovative technologies designed to extend shelf life. These machines utilize various methods, including vacuum sealing, modified atmosphere packaging (MAP), and heat sealing, to create an optimal protective environment for food items. For instance, vacuum sealing removes excess air from the packaging, significantly slowing down the degradation process caused by oxidation. This method is particularly effective for perishable goods, helping to maintain flavor and nutritional value over time.

Moreover, the technology behind modified atmosphere packaging involves altering the composition of gases inside the package, replacing oxygen with nitrogen or carbon dioxide. This controlled environment inhibits the growth of aerobic bacteria and molds, further ensuring that the food remains fresh. Heat sealing machines, on the other hand, provide a reliable barrier against moisture and contaminants, which are key factors that can lead to spoilage. Together, these advanced packaging technologies not only enhance product freshness but also contribute to reducing food waste, making them an essential component of modern food preservation strategies.

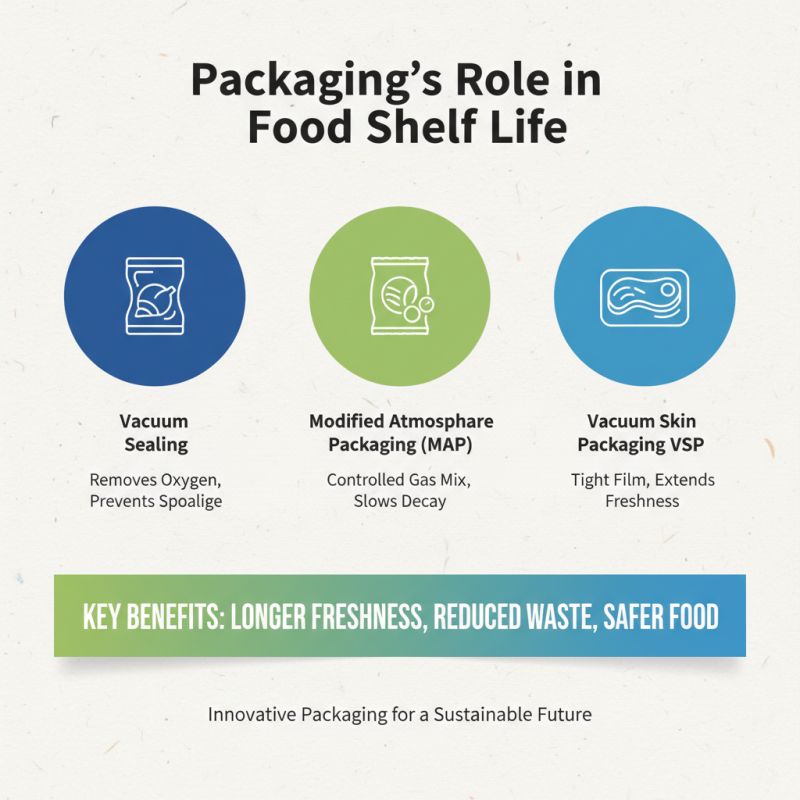

Impact of Packaging Techniques on Food Shelf Life: Industry Insights

The impact of packaging techniques on food shelf life is a critical consideration in the food industry. Innovative packaging solutions are designed to create an optimal environment for food preservation, significantly extending the period during which products remain fresh and safe for consumption. Techniques such as vacuum sealing, modified atmosphere packaging (MAP), and the use of vacuum skin packaging (VSP) can effectively slow down the degradation processes caused by exposure to oxygen, moisture, and light. By minimizing these detrimental factors, these advanced methods reduce spoilage and retain the quality of food products for longer durations.

Moreover, the choice of materials plays a pivotal role in maintaining food freshness. Barrier films that prevent the ingress of gases and moisture, along with biodegradable options that lessen environmental impact, are gaining traction in the market. The industry is increasingly recognizing the importance of balancing food safety with sustainability, leading to the development of eco-friendly packaging that meets consumer demands without compromising on the shelf life of products. With these advancements, food packaging machines are not just tools but essential components in the quest to enhance food longevity and quality, ultimately benefiting both manufacturers and consumers alike.

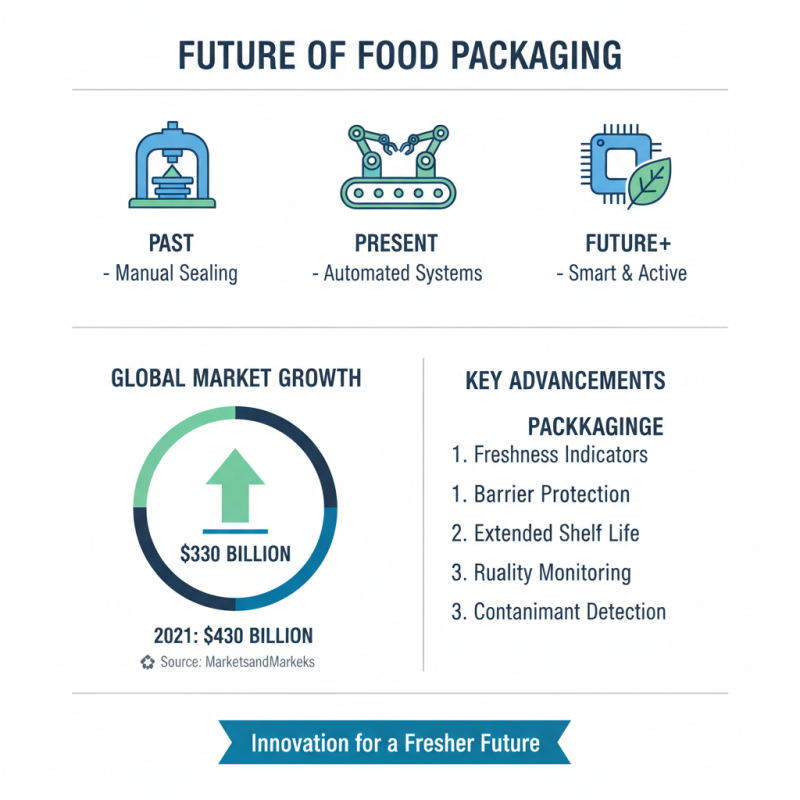

Future Trends in Food Packaging Machines: Innovations for Preservation

The evolution of food packaging machines has significantly impacted the preservation of food products, with future trends focusing on advanced technologies that ensure freshness and extend shelf life. According to a report by MarketsandMarkets, the global food packaging market is expected to grow from USD 330 billion in 2021 to USD 450 billion by 2026, showcasing the increasing demand for innovative packaging solutions. These advancements involve the integration of smart packaging technologies that not only provide a barrier to external contaminants but also include indicators that monitor freshness and quality over time.

One of the most promising trends in food packaging machines is the development of biodegradable and compostable materials. Research indicates that 51% of consumers are willing to pay more for environmentally friendly packaging, reflecting a shift towards sustainability in the food industry. Additionally, companies are investing in vacuum packaging and modified atmosphere packaging (MAP) technology, which have been shown to reduce spoilage rates by up to 30%. These innovations not only help in maintaining food quality but also align with consumer expectations for eco-conscious practices, driving the market towards more sustainable production and packaging methods.

Related Posts

-

Top 10 Custom Packaging Machines to Boost Your Business Efficiency in 2023

-

Innovative Material Handling Carts for Efficient Workplace Organization and Productivity

-

Revolutionizing Packaging: How Automatic Bagging Machines Enhance Efficiency and Precision in Industries

-

Mastering Efficiency: How VFFS Machines Revolutionize Packaging Processes for Modern Businesses

-

Transform Your Workspace: The Ultimate Guide to Selecting the Perfect Material Handling Carts

-

Top 5 Custom Packaging Machine Trends Driving Efficiency and Growth in 2023