2025 How to Choose the Best Automatic Packaging Machines for Your Business

In the fast-evolving landscape of modern manufacturing, the selection of the right automatic packaging machines plays a pivotal role in enhancing operational efficiency and ensuring product integrity. Industry expert Dr. Emily Carter, a renowned figure in packaging technology, emphasizes this point by stating, "The right automatic packaging machine can not only streamline production processes but also significantly reduce waste and improve product shelf life." As competition intensifies, businesses must carefully evaluate their options to find machines that cater to their unique needs and scaling requirements.

The decision-making process surrounding automatic packaging machines can be overwhelming, given the myriad of choices available. Factors such as machinery durability, compatibility with existing production lines, and the ability to adapt to future demands are critical considerations that can impact overall productivity and profitability. Understanding the features and benefits of various machines will empower business owners to make informed decisions that align with their long-term growth strategies.

Investing in high-quality automatic packaging machines is no longer a luxury but a necessity for companies aiming to maintain a competitive edge. By leveraging expert insights and understanding the latest trends in packaging technology, businesses can optimize their operations, enhance their brand’s appeal, and ultimately ensure customer satisfaction.

Understanding the Basics of Automatic Packaging Machines

Automatic packaging machines play a crucial role in modern manufacturing and logistics, significantly enhancing efficiency and reducing labor costs. The global automatic packaging market is expected to reach a value of approximately $50 billion by 2025, driven by increasing demand for efficient packaging solutions across various industries. Understanding the basic types of automatic packaging machines—such as form-fill-seal, vertical and horizontal form-fill-seal machines, and tray sealers—will enable businesses to make informed decisions tailored to their operational needs.

When selecting an automatic packaging machine, factors such as production speed, machine size, and compatibility with existing production lines are essential considerations. For instance, the average output for high-speed packaging machines can range from 100 to 300 packages per minute, which significantly impacts overall productivity. Additionally, industry reports indicate that over 60% of manufacturers prioritize automation to improve packaging consistency and reduce waste, demonstrating the importance of investing in the right technology that aligns with both budget and scalability. By assessing these fundamental aspects, businesses can ensure they choose an automatic packaging solution that not only meets current demands but is also adaptable to future growth.

Identifying Your Business Needs for Packaging Solutions

When considering the selection of automatic packaging machines for your business, the first step is to clearly identify your specific needs. Understanding the nature of your product is crucial; different items may require varied packaging techniques, materials, and protective features.

For instance, delicate products might need cushioned packaging to prevent damage, while items intended for long-distance shipping may require more rugged solutions to withstand transit conditions. Additionally, consider the volume of production—high-output operations may benefit from faster packing speeds and automation levels, while smaller operations might focus on flexibility and ease of use.

Once you have a clear understanding of your product characteristics, the next step involves evaluating your operational requirements. This includes analyzing your production space, labor resources, and budget constraints. Knowing whether you need a standalone machine or a fully integrated system can significantly streamline your decision-making process.

Take the time to assess the layout of your production area, as well as how the equipment will fit into your existing workflow. A well-chosen packaging machine not only enhances efficiency but also reduces labor costs, so ensure that your choice aligns with both your current operations and future growth plans.

Key Features to Consider When Selecting Packaging Equipment

When selecting automatic packaging machines for your business, there are several key features that should not be overlooked. First and foremost, consider the machine's speed and efficiency. High-speed machines can significantly enhance productivity, but it is crucial to match the machine’s capabilities with your production volume to ensure an effective workflow. Look for models that offer adjustable speed settings, enabling you to customize operations based on varying production demands.

Another essential factor is the versatility of the machine. As market trends evolve, your packaging requirements may change. Opt for machines that can handle different types of packaging materials and sizes. This flexibility allows for easier adaptation to new product lines without the need for a costly investment in new equipment. Additionally, prioritize machines equipped with easy changeover features, which can save valuable time and resources during production shifts.

Tips: Always request a demonstration or trial period before finalizing your purchase. This can help ensure the machine meets your specific needs. Don't hesitate to ask about maintenance and support options, as reliability is a critical aspect of minimizing downtime and keeping your operations running smoothly. Finally, consider investing in machines that include advanced technology, such as smart sensors or integration with inventory management systems, to enhance overall efficiency.

Comparing Different Types of Automatic Packaging Machines

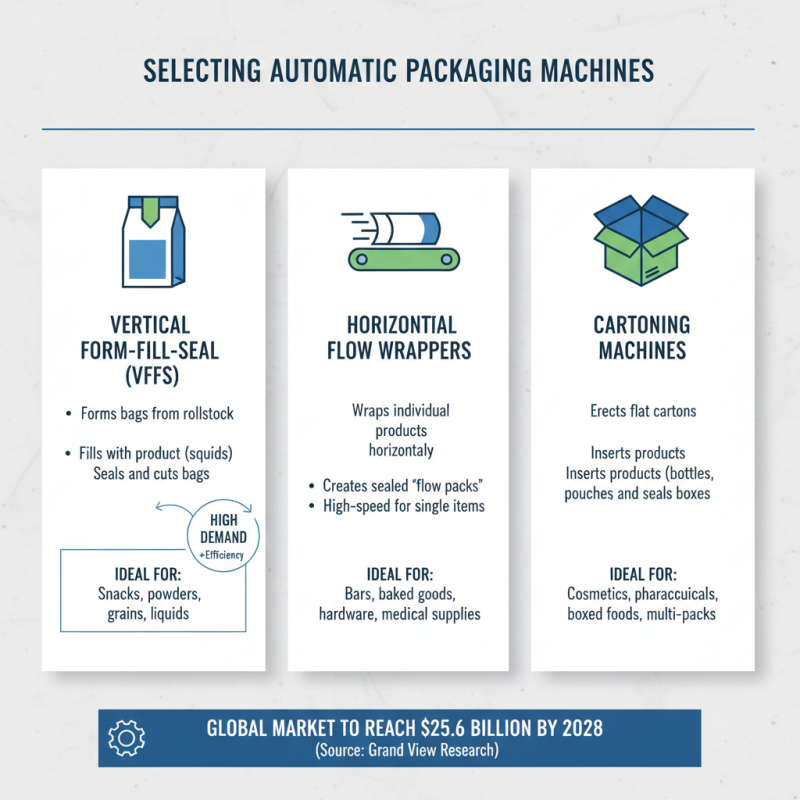

When selecting the best automatic packaging machines for your business, it's essential to compare the different types available on the market. The main categories of automatic packaging machines include vertical form-fill-seal (VFFS) machines, horizontal flow wrappers, and cartoning machines. According to a report by Grand View Research, the global automatic packaging market size is expected to reach $25.6 billion by 2028, with a significant rise in demand for VFFS machines due to their efficiency in packaging food and consumer goods.

Vertical form-fill-seal machines are popular for their ability to package products in various shapes and sizes quickly. They allow businesses to reduce material waste while maintaining product integrity and shelf life. A study from Allied Market Research indicates that the VFFS segment accounted for over 35% of the total market share in 2020, showcasing its effectiveness in high-speed packaging lines. Conversely, horizontal flow wrappers are ideal for packaging items like snacks and confectioneries. They excel in flexibility and ease of use, making them a preferred choice for businesses looking to streamline their packaging process.

When choosing an automatic packaging machine, it's crucial to consider the specific needs of your products, including size, volume, and packaging format. Additionally, efficiency and operational costs are vital factors; automating your packaging can lead to a reduction in labor costs and increase productivity. According to the Packaging Machinery Manufacturers Institute (PMMI), companies that have successfully integrated automatic packaging systems reported efficiency improvements of up to 30%. By carefully evaluating these various types of machines, businesses can enhance their packaging operations and stay competitive in an ever-evolving market.

Evaluating Costs and ROI for Packaging Machinery Investments

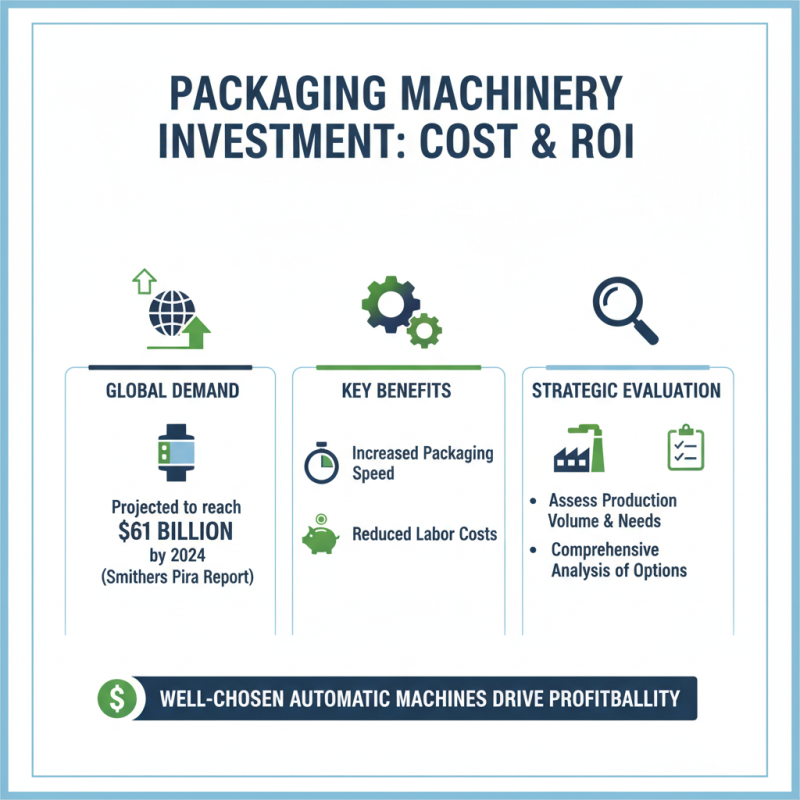

When evaluating costs and ROI for packaging machinery investments, businesses must consider various factors that contribute to overall efficiency and profitability. According to a report by Smithers Pira, the global demand for packaging machinery is expected to reach $61 billion by 2024, which highlights the growing importance of investing in advanced technology. A well-chosen automatic packaging machine not only increases packaging speed but also significantly reduces labor costs. As businesses assess their packaging needs, they should conduct a comprehensive analysis of potential machinery options to identify those that align with production volume and specific requirements.

Evaluating ROI requires businesses to consider both direct and indirect costs associated with new machinery. Direct costs include initial purchase, installation, and maintenance expenses, while indirect costs encompass labor savings, increased production efficiency, and potential reductions in waste. For instance, a study published in Packaging World highlighted that optimizing packaging processes could lead to savings of up to 30% in operational costs. Furthermore, the ability to scale operations with automated solutions can enhance a company’s adaptability to changing market demands, ultimately improving long-term profitability. This holistic approach to assessing costs and ROI ensures that businesses make informed decisions that support their growth objectives.

Related Posts

-

Top 5 Benefits of Using an Automated Packaging Machine for Your Business

-

Top 10 Custom Packaging Machines to Boost Your Business Efficiency in 2023

-

Why Your Business Needs an Industrial Packing Machine for Efficiency and Growth

-

Revolutionizing the Food Industry How Food Packaging Machines Enhance Freshness and Sustainability

-

Top Packaging Equipment Trends You Need to Know for Your Business

-

10 Best Custom Packaging Machines for Your Business Needs