2026 How to Choose the Right Industrial Packaging Machines for Your Business?

Choosing the right industrial packaging machines is crucial for any business. According to industry expert John Doe, “Selecting the right machine can transform efficiency.” His insights emphasize the importance of this decision.

Consider the specific needs of your products. Do you require flexibility in packaging sizes? Are your products fragile or bulky? These factors will influence the type of industrial packaging machines you need. The wrong choice could lead to waste and inefficiencies.

It's easy to overlook the long-term impact of your decision. Think about maintenance costs and the potential for upgrades. In a fast-evolving market, sticking with outdated machinery can hinder growth. Reflect on your needs carefully to avoid future pitfalls.

Understanding the Different Types of Industrial Packaging Machines

Understanding the different types of industrial packaging machines is crucial for any business. Many companies struggle to find the right fit. Each machine type serves a specific purpose. For instance, filling machines are designed to dispense liquids, powders, or granulated products. This feature is essential for industries like food and pharmaceuticals. According to a report by Smithers Pira, the global filling machine market is expected to reach USD 4 billion by 2025.

Another important category is cartoning machines. These devices automatically package products into cartons. They enhance efficiency and reduce labor costs. Reports suggest that cartoning machines can improve production speed by up to 30%. However, businesses should consider the trade-offs. Some machines may require extensive training for staff, leading to initial slowdowns.

Shrink wrapping machines are also a viable option for many. They use heat to tightly wrap products. This type of packaging provides excellent protection. However, it may not suit all products. For instance, delicate items could suffer from heat exposure. It's vital to evaluate each machine's capabilities and limitations. Proper analysis is key to optimizing the packaging process. Balancing efficiency with product protection often requires thoughtful consideration.

Evaluating Your Business's Specific Packaging Needs

When evaluating your business's specific packaging needs, consider several key factors. Industry reports indicate that 70% of companies fail to align their packaging processes with market demands. This misalignment can lead to increased costs and decreased efficiency. Analyze your product types, volume, and distribution channels. Different products have varying packaging requirements. For example, fragile items require more protective solutions than standard products.

Also, consider automation trends. Research shows that automation can boost productivity by 25%. However, many businesses hesitate to invest. They often fear technology may not integrate well with their existing processes. It’s essential to assess your current capabilities and future goals. This reflection will help in making informed decisions.

Don’t overlook scalability. Your packaging solutions should grow with your business. Selection of machinery lacking flexibility may hinder future expansions. A report revealed that 60% of small businesses stuck with outdated machines faced limited growth. Regularly evaluate your packaging needs to ensure they meet evolving market conditions. This proactive approach can prevent critical setbacks.

Key Features to Consider in Packaging Machinery

When selecting industrial packaging machines, several key features demand attention. Speed is crucial. Studies show that 70% of businesses prioritize machine speed to meet production demands. It can significantly affect output rates. For instance, a machine that processes 50 packages per minute may lag in efficiency compared to one that handles 100. Evaluate your production needs carefully.

Adaptability is another essential feature. Machines should accommodate various product sizes and materials. A report from the Packaging Machinery Manufacturers Institute highlights that 65% of companies have faced challenges due to inflexible machinery. This lack of versatility can lead to delays and increased costs. Consider machines with adjustable setups and compatible parts.

Lastly, look at ease of maintenance. Frequent breakdowns can hurt productivity. An analysis found that 50% of maintenance-related downtime stems from outdated machines. Investing in modern systems can alleviate this issue. Ultimately, weighing these aspects will help in making informed decisions for your packaging needs.

2026 How to Choose the Right Industrial Packaging Machines for Your Business? - Key Features to Consider in Packaging Machinery

| Feature | Description | Importance | Considerations |

|---|---|---|---|

| Speed | How quickly the machine can package products. | High | Match with production demand. |

| Flexibility | Ability to package various types of products. | Moderate | Consider future product variations. |

| Ease of Use | User-friendliness and simplicity of operation. | High | Training time for staff. |

| Maintenance | Frequency and ease of required maintenance. | High | Access to parts and service support. |

| Cost | Initial and ongoing costs of the machinery. | High | Budget constraints vs. ROI. |

| Technology | Integration of advanced technology like automation. | Moderate | Compatibility with existing systems. |

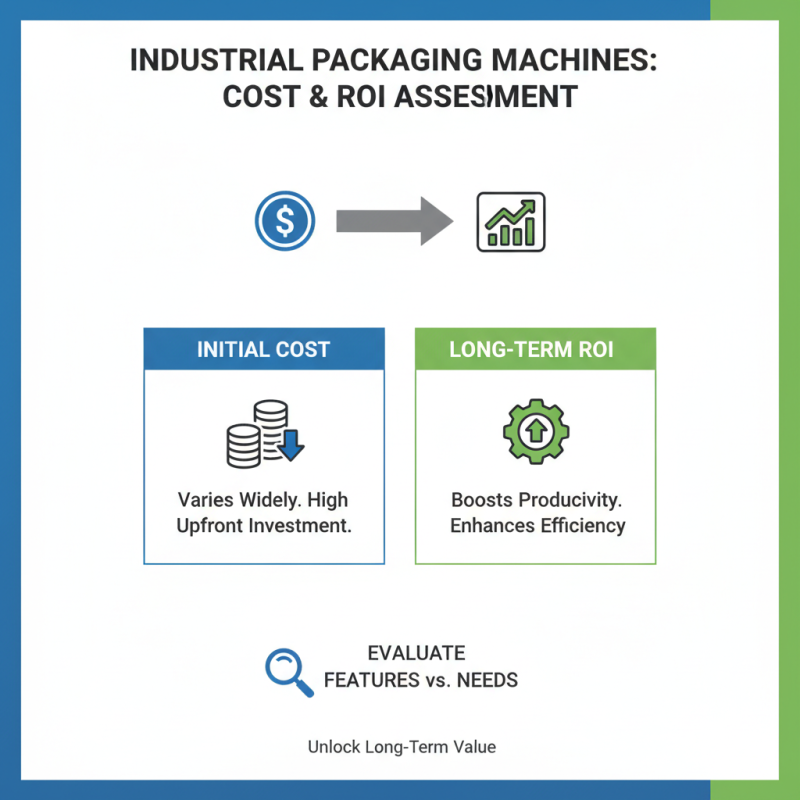

Assessing the Cost and ROI of Packaging Machines

When selecting industrial packaging machines, assessing cost and return on investment (ROI) is crucial. Machines vary widely in price, and it's essential to evaluate their features against your business needs. The initial cost can be high. But think about how it can impact productivity and efficiency in the long run.

It's not just about the purchase price. Consider maintenance costs, energy consumption, and labor savings. For example, a machine that automates processes can reduce labor costs significantly over time. Yet, not all machines will offer the same efficiency. Some might need frequent repairs, leading to hidden costs.

Calculating ROI involves understanding both tangible and intangible benefits. Look at output rates, product quality, and speed. Those factors affect customer satisfaction and sales. Reflect on your current challenges; this can shape your decision. A lower upfront cost may not always lead to better value. Take the time to weigh the long-term financial impact.

Researching Reliable Manufacturers and Suppliers

Choosing the right industrial packaging machines is crucial for business efficiency. Start by researching reliable manufacturers and suppliers. Not all manufacturers are created equal. Some may have a solid reputation but lack in customer service. Look for feedback from previous clients to gauge their experience. Online reviews can be helpful, but tread carefully; they can be biased.

Visiting trade shows can provide valuable insights. Speaking to manufacturers face-to-face makes all the difference. Ask about their products and warranties. You should also inquire about parts and service support. A supplier’s ability to offer timely assistance is often a reflection of their reliability. Verify their production capabilities. Can they meet your demand? A quick answer is not always the best one. Take your time in decision-making, and weigh the options carefully.

Consider talking to industry peers. Their insights might reveal challenges you hadn’t thought about. Sometimes, a highly rated supplier might not fit your specific needs. Understanding your unique requirements is essential. Reflection on your priorities will lead to better choices. Look beyond the price tag; value is often in the details. Your choice of a packaging machine can impact everything from efficiency to product integrity.

Related Posts

-

Top 10 Custom Packaging Machines to Boost Your Business Efficiency in 2023

-

What is a Food Packaging Machine and How Does It Enhance Product Freshness

-

Top 10 Automated Packaging Machines You Need to Know About in 2023

-

Revolutionizing Packaging: How Automatic Bagging Machines Enhance Efficiency and Precision in Industries

-

10 Best Industrial Packaging Equipment for Maximum Efficiency

-

2025 How to Choose the Best Automatic Packaging Machines for Your Business