Why Industrial Packaging Equipment is Essential for Modern Business Success?

In today's competitive market, the importance of industrial packaging equipment cannot be overstated. Experts like John Smith, a renowned leader in packaging solutions, emphasize, "Efficient packaging is vital for logistics and customer satisfaction." This underscores a growing recognition within the business community.

Industrial packaging equipment plays a crucial role in streamlining operations. It enhances efficiency, reduces waste, and ultimately lowers costs. Many businesses overlook the impact of outdated equipment on their productivity. Without the right tools, companies may struggle to meet deadlines or exceed customer expectations.

Yet, the adoption of advanced industrial packaging systems can be challenging. The initial investment may deter some enterprises. However, the long-term benefits often outweigh these concerns. As the market evolves, businesses must adapt or risk falling behind. Embracing modern industrial packaging equipment is not just a choice; it is a necessity for thriving in today’s economy.

The Role of Industrial Packaging Equipment in Supply Chain Efficiency

In today's fast-paced market, industrial packaging equipment plays a crucial role. It enhances supply chain efficiency by ensuring products are well-protected during transit. This equipment helps in minimizing damages and losses, which can disrupt the flow of goods. Effective packaging reduces the likelihood of returns, ensuring customer satisfaction.

A good example is automated packaging machines. They speed up the packing process and minimize human error. However, relying solely on automation can lead to concerns. There could be breakdowns or errors in programming. This requires constant monitoring and adjustments.

Another aspect to consider is the use of sustainable materials. Many companies are shifting toward eco-friendly packaging. While this is admirable, it can complicate logistics. Some biodegradable materials may not hold up as well during shipping. Balancing efficiency and sustainability is essential, yet it can be challenging. Addressing these complexities is a step towards better supply chain management.

Why Industrial Packaging Equipment is Essential for Modern Business Success? - The Role of Industrial Packaging Equipment in Supply Chain Efficiency

| Aspect | Description | Importance |

|---|---|---|

| Cost Efficiency | Reduces packaging and shipping costs through optimized design. | High impact on overall operational costs. |

| Protection | Prevents damage during transportation and storage. | Crucial for maintaining product quality. |

| Sustainability | Uses recyclable and eco-friendly materials. | Meets consumer demand for sustainable practices. |

| Automation | Incorporates technology for faster packing processes. | Increases efficiency and reduces labor costs. |

| Customization | Allows tailored solutions for specific products. | Enhances customer satisfaction and branding. |

Impact of Industrial Packaging on Product Safety and Quality Assurance

Industrial packaging plays a critical role in product safety and quality assurance. The right packaging prevents damage during transportation and storage. It also protects against environmental factors like moisture and contamination. Ensuring that products arrive in perfect condition is vital for customer satisfaction.

However, not all packaging solutions are effective. Some materials may not provide adequate protection. This can lead to increased return rates and loss of trust. Businesses must regularly evaluate their packaging choices. It is crucial to balance cost with performance. Simple changes can significantly improve product integrity.

Additionally, innovative designs can enhance safety. Custom packaging molds cater to specific products. This minimizes movement and potential harm. Yet, companies often overlook proper testing. Relying on assumptions can lead to underwhelming results. Continuous improvement and adaptation are necessary for achieving optimal outcomes in packaging.

Cost-Effectiveness of Investing in Industrial Packaging Solutions

Investing in industrial packaging solutions offers notable cost-effectiveness for modern businesses. According to recent industry reports, companies that optimize their packaging can reduce costs by up to 30%. This is crucial in a competitive market where every dollar counts. Efficient packaging minimizes waste, protects products, and often reduces shipping costs.

Automation in packaging helps streamline operations, increasing productivity. Businesses that utilize packaging technology experience an average of 20% lower labor costs. However, many companies fail to adopt these solutions. They hold onto outdated manual processes, which can lead to higher operational costs in the long run. This reluctance can be detrimental as competitors leverage more efficient methods.

Sustainability is another aspect of cost-effectiveness. Eco-friendly packaging solutions not only appeal to consumers but can also lead to tax incentives. A survey found that 74% of consumers are willing to pay more for sustainable options. Yet, companies often struggle to balance costs with sustainability. Finding the right balance requires thoughtful consideration. The truth is, the right industrial packaging can transform a business's bottom line, yet many overlook this opportunity.

Technological Advancements in Industrial Packaging Equipment

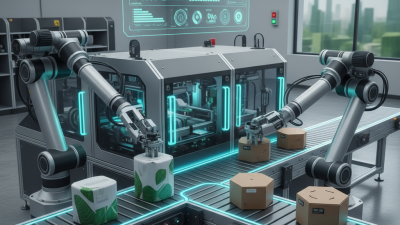

Technological advancements in industrial packaging equipment have dramatically transformed modern businesses. It’s not just about wrapping products anymore. It includes automation, smart technology, and eco-friendly materials. According to a recent industry report, the global industrial packaging market is expected to grow by 5.3% annually by 2026. This growth is largely driven by the need for efficiency and product safety.

One major trend is the integration of IoT technology. Sensors in packaging equipment can track real-time data, ensuring optimal performance. However, many companies struggle to keep up with these innovations. Staying informed and adapting can be challenging but crucial.

Tips: Regularly evaluate your packaging processes to identify areas for improvement. Investing in training for your team can enhance productivity.

Sustainability is also a key focus. Businesses are shifting to biodegradable materials, appealing to eco-conscious consumers. Yet, this transition can be complicated. Balancing sustainability with cost-effectiveness requires thoughtful planning. Companies often underestimate the necessary adjustments in production.

Why Industrial Packaging Equipment is Essential for Modern Business Success

This chart illustrates the impact of technological advancements in industrial packaging equipment on operational efficiency, cost reduction, and sustainability in modern businesses.

Sustainability Trends Influencing Industrial Packaging Practices

Sustainability trends are reshaping industrial packaging practices. Businesses are under pressure to reduce their environmental impact. Eco-friendly materials are gaining favor. This shift is not merely a trend; it is pivotal for success.

Packaging made from recycled materials can enhance brand image. Consumers care about sustainability. They expect businesses to act responsibly. Companies that ignore this trend risk losing market share. Recycled content improves waste management and reduces material costs.

Tips: Consider using biodegradable packaging. It's effective for food and consumer goods. Also, explore reusable packaging options. They can cut costs in the long run. Don't overlook the importance of educating staff about sustainable practices. Training programs can foster a culture of responsibility within your organization.

It's essential to evaluate current packaging processes regularly. Companies may discover hidden inefficiencies that contradict sustainability goals. Embracing new technologies can streamline processes, reducing waste. Reflecting on and adjusting packaging strategies is crucial for ongoing relevance.

Related Posts

-

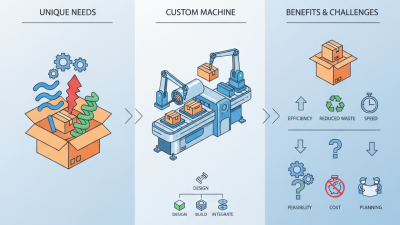

What is a custom packaging machine and how does it work?

-

Revolutionizing Efficiency: How Automated Packaging Machines Transform Your Production Line

-

Revolutionizing Supply Chains: The Future of Industrial Packaging Equipment Explained

-

Top 5 Custom Packaging Machine Trends Driving Efficiency and Growth in 2023

-

2025 How to Choose the Best Automatic Packaging Machines for Your Business

-

Top 10 Automated Packaging Machines You Need to Know About in 2023