Why Your Business Needs an Industrial Packing Machine for Efficiency and Growth

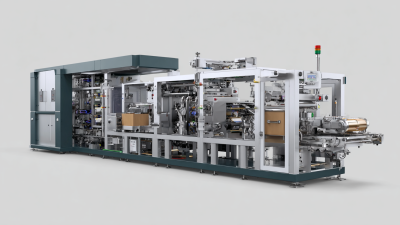

In today's highly competitive business landscape, the efficiency of packaging processes can significantly impact a company's growth trajectory. An industrial packing machine is more than just a piece of equipment; it serves as a crucial investment that can streamline operations, enhance product safety, and improve overall productivity.

According to a report by MarketsandMarkets, the global packaging machinery market is projected to reach USD 55.96 billion by 2025, growing at a CAGR of 3.9%. This growth underscores the importance of modernizing packaging processes to meet evolving consumer demands.

Furthermore, the adoption of industrial packing machines can lead to considerable reductions in labor costs and errors associated with manual packing. The International Society for Automation reported that automating packing processes can reduce labor costs by up to 30% and increase efficiency by up to 50%. By leveraging industrial packing machines, businesses not only improve their operational workflows but also position themselves for sustainable growth in a market that increasingly values speed and reliability. As companies strive to maintain competitive edge, the importance of investing in high-quality industrial packing machines cannot be overstated.

The Role of Industrial Packing Machines in Streamlining Operations

Industrial packing machines play a vital role in streamlining operations within manufacturing environments. As businesses aim for efficiency and growth, these machines help meet the ever-present demands for higher quality products, lower costs, and faster delivery. The injection molding market is projected to reach $1.2 billion globally by 2025 and grow to $1.97 billion by 2035, indicating the increasing reliance on efficient packing solutions to lead industry transformation.

Implementing advanced packing machines, such as automatic shrink wrap machines, enhances productivity significantly. The market for fully automatic shrink packaging machines is expected to grow from $1.44 billion in 2025 to $2.18 billion by 2034, with a compound annual growth rate of 4.7%. This growth reflects the need for packaging solutions that not only protect products but also optimize labor costs and reduce waste.

Tips: To ensure you are maximizing the benefits of an industrial packing machine, regularly assess your operations for bottlenecks that could be alleviated through automation. Additionally, consider investing in machines that can adjust to varying product sizes to enhance flexibility in production. Lastly, always stay informed about the latest technology advancements to keep your packing process ahead of the competition.

Key Advantages of Implementing Industrial Packing Solutions

Implementing industrial packing solutions can significantly enhance operational efficiency and facilitate growth for businesses across various sectors. One of the key advantages lies in the automation capabilities offered by modern packing machines, which streamlines the packing process, reduces manual labor, and minimizes the risk of human error. By automating packing tasks, businesses can optimize their workflow, allowing for faster turnaround times and increased productivity. This efficiency not only helps in meeting consumer demand more effectively but also positions the company to scale operations as needed.

Moreover, the integration of artificial intelligence in packing solutions is reshaping the industry by promoting smarter, data-driven practices. AI technology enhances packing design by analyzing consumer behavior and preferences, leading to innovative packaging materials and structures that cater to specific market needs. This shift towards intelligent packaging not only reduces material waste but also improves sustainability efforts, which are increasingly prioritized by consumers. As the packaging market continues to evolve, embracing these advanced solutions is essential for companies looking to maintain competitiveness and adapt to the changing landscape of consumer demands and environmental considerations.

How to Choose the Right Packing Machine for Your Business Needs

When selecting the right packing machine for your business needs, it is essential to consider several factors that align with your operational goals and the evolving market demands. With the increasing emphasis on eco-friendly packaging solutions, especially in the beverage box packaging sector, choosing a machine that accommodates sustainable practices can give your business a competitive edge. Modern consumers are gravitating towards environmentally friendly options, making it imperative for companies to adopt packaging that not only meets functional requirements but also resonates with eco-conscious values.

Additionally, understanding the different types of packing machines available—ranging from semi-automatic to fully automatic machines—can significantly impact efficiency and scalability. Assessing your production volume, workflow requirements, and space constraints will aid in selecting a machine that optimizes performance. Furthermore, as trends in the food and beverage industry continue to evolve, investing in versatile packing machines that can adapt to various products and packaging types is crucial for growth. By making informed choices based on these considerations, you can ensure that your packaging process supports both current demands and future expansion.

Maximizing Efficiency: Maintenance Tips for Packing Equipment

Proper maintenance of industrial packing machines is crucial for maximizing efficiency and ensuring seamless operations in your business. According to a report by the Freedonia Group, the demand for packaging machinery is projected to reach $25 billion by 2024, highlighting the critical role these machines play in the manufacturing process. Regular maintenance not only minimizes the risk of unexpected breakdowns but also extends the lifespan of the equipment, leading to improved productivity.

To keep your packing equipment running optimally, it’s essential to implement a scheduled maintenance plan. This includes routine inspections, lubrication of moving parts, and prompt repair of any identified issues. A study by PMMI found that businesses that adhere to regular maintenance schedules experience up to a 25% reduction in downtime, translating into significant cost savings and enhanced operational efficiency. Training staff on proper handling and maintenance protocols can also dramatically improve the overall performance of packing machines, ensuring that your business can scale and grow effectively in today’s competitive marketplace.

Future Trends: Innovations in Industrial Packing Technology

In today's fast-paced industrial landscape, the need for efficient packing solutions is more critical than ever. As businesses strive to enhance productivity and sustainability, innovations in industrial packing technology are paving the way for future growth. According to recent reports, the global industrial labeling market is projected to reach a staggering $94.42 billion by 2030, driven by a compound annual growth rate (CAGR) of 7.50%. This expansive growth highlights the demand for advanced packing machinery that can adapt to evolving market trends.

As companies increasingly focus on sustainable practices, the implementation of eco-friendly packaging materials has surged. Recent studies reveal that the focus on sustainable packaging is accelerating, particularly in regions like Southeast Asia, where the paper packaging industry is expected to experience significant growth through 2025. Incorporating these sustainable practices not only aligns with consumer preferences but also enhances a company's operational efficiency.

Tip: Consider investing in industrial packing machines that utilize recyclable materials and optimize packing processes to meet sustainability goals. Additionally, leveraging innovations such as AI and blockchain can enhance quality control and streamline the packing workflow. These steps can help businesses not only stay competitive but also contribute to a greener future.

Related Posts

-

Revolutionizing Efficiency: How Automated Packaging Machines Transform Your Production Line

-

Top 10 Custom Packaging Machines to Boost Your Business Efficiency in 2023

-

Top 5 Benefits of Using an Automated Packaging Machine for Your Business

-

Revolutionizing the Food Industry How Food Packaging Machines Enhance Freshness and Sustainability

-

10 Best Custom Packaging Machines for Your Business Needs

-

Top 10 Packaging Automation Equipment for Streamlining Your Production Process