What is Packaging Equipment and How Does it Work?

Packaging equipment plays a crucial role in various industries. It encompasses machines that package products for distribution and sale. According to a report by MarketsandMarkets, the global packaging equipment market is projected to reach $50 billion by 2026. This growth stems from increasing demand for efficient packaging solutions that ensure product safety.

Experts highlight the importance of innovation in packaging equipment. John Smith, a renowned figure in the packaging industry, stated, "Efficiency and adaptability are key for today’s packaging equipment." His insights underline the need for equipment that can handle diverse products and meet consumer expectations. However, as technology evolves, manufacturers must address challenges such as sustainability and cost-effectiveness.

In the ever-changing landscape of the packaging sector, the implementation of advanced machinery is crucial. Companies are compelled to rethink their strategies for packaging equipment to stay competitive. The pursuit of perfection often leads to unforeseen hurdles. Thus, continuous reflection on both performance and design is necessary to achieve optimal results.

Definition of Packaging Equipment and Its Importance in Industries

Packaging equipment plays a vital role in various industries. It is designed for the efficient packaging of products to ensure protection and improve shelf life. This equipment includes machines for filling, sealing, labeling, and wrapping goods. An industry report indicates that the global packaging machinery market is expected to reach $50 billion by 2026, highlighting its importance.

The efficiency of packaging equipment directly impacts operational costs. Companies seek ways to minimize waste and enhance speed. An effective packaging line can reduce the packing time by 30%. However, it is crucial to choose the right equipment for your products. Mismatched machinery may lead to inefficiencies or product damages.

Tips: Always assess your production volume. Select a machine that fits your specific needs. Regular maintenance also enhances performance and longevity. If the equipment breaks down frequently, it might not be suitable for your operations. Analyze and reflect on your choices.

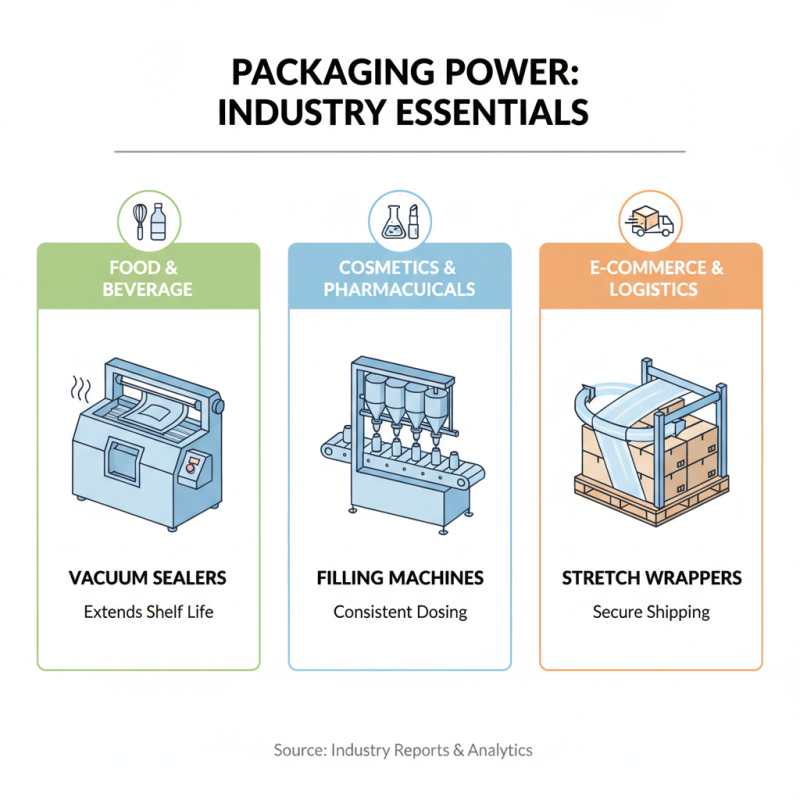

Types of Packaging Equipment Used in Various Sectors

Packaging equipment plays a crucial role in many industries. Different sectors rely on various types of equipment to meet their packaging needs. For example, food manufacturers often use vacuum sealers. These machines extend product shelf life by removing air from bags. In the cosmetic industry, one might find filling machines. They ensure consistent product amounts in every container.

Moreover, packaging for pharmaceuticals demands high precision. Here, blister packaging machines are commonly used. They provide a protective seal that maintains product integrity. E-commerce and retail sectors favor automated packing systems. These systems increase efficiency by rapidly boxing items for shipment. The variety in packaging methods poses challenges too. Companies may struggle with choosing the right machinery. They often must balance cost with efficiency.

Inevitably, not every solution fits every need. Some businesses may invest in equipment that ultimately doesn’t serve their purpose. It’s essential to evaluate the specific requirements of each industry. Understanding how to customize machinery can aid in reducing waste. Packaging equipment should not just meet demand; it should evolve with market trends. Maximizing functionality is a continuous journey for many.

How Packaging Equipment Operates: Basic Principles and Mechanisms

Packaging equipment plays a crucial role in modern manufacturing. It helps in filling, sealing, and labeling products efficiently. Understanding how this equipment operates is essential for optimizing production lines.

At its core, packaging equipment relies on several basic principles. Many machines use sensors to detect product presence. This ensures accurate filling. Motors drive the machinery, moving products along conveyor belts. This movement must be precise. If not, products may jam or get damaged.

Tip: Regular maintenance of packaging equipment is vital. It prevents unexpected downtime. Check belts and gears for wear regularly.

Another critical mechanism is the sealing process. Different methods include heat sealing or pressure sealing. Each method has its pros and cons. Heat sealing is fast but can lead to product spoilage. Pressure sealing, on the other hand, is safer for sensitive items but may be slower.

Tip: Test packaging options before full-scale production. Small trials can reveal flaws in the process. Adjustments save time and resources later.

Always monitor the operation of your equipment. Fluctuations in speed or temperature can indicate issues. Catching problems early can prevent larger breakdowns.

Key Factors to Consider When Selecting Packaging Equipment

When selecting packaging equipment, several key factors should be considered. Efficiency is vital. With studies showing that automated packaging can boost productivity by up to 30%, choosing a system that aligns with your output needs is crucial. A machine must match your production volume and speed. Different products require different packaging methods, so flexibility is essential.

Another aspect is technology. Advanced features like smart sensors and AI integration are transforming the industry. These technologies can reduce waste and improve accuracy. A report from the Packaging Machinery Manufacturers Institute (PMMI) indicates that 80% of manufacturers are investing in automation to enhance their operations.

**Tips:** Always evaluate the learning curve. Complex machines might require extensive training. Cost is also a concern. Initial expenses can be high, but consider long-term savings. Finally, prioritize durability. Equipment that breaks down frequently can lead to unexpected costs and downtime. It's essential to balance initial investments with potential return on investment.

What is Packaging Equipment and How Does it Work? - Key Factors to Consider When Selecting Packaging Equipment

| Packaging Equipment Type | Functionality | Key Features | Considerations for Selection |

|---|---|---|---|

| Filling Machines | Fill containers with products such as liquids, powders, or granules. | Automated filling, adjustable fill volume, accuracy. | Product compatibility, filling speed, ease of cleaning. |

| Labeling Machines | Apply labels to products or packaging. | Speed control, flexibility for different shapes, integration. | Label size, material, automation level. |

| Sealing Machines | Seal packages to ensure product safety and freshness. | Heat sealing, vacuum sealing, integrity checking. | Sealing method, material compatibility, durability. |

| Wrapping Machines | Wrap products in plastic, paper, or other materials. | Stretch wrapping, shrink wrapping, bundling. | Product dimensions, wrapping speed, film type. |

| Cartoning Machines | Package products into cartons. | Automatic folding, packing efficiency, integration. | Carton size, product orientation, automation level. |

Future Trends in Packaging Equipment Technology and Innovation

The packaging equipment industry is evolving rapidly. Recent reports indicate that the market is expected to reach $50 billion by 2026. Automation is a significant trend driving growth. Manufacturers increasingly utilize smart machinery that enhances efficiency and reduces waste. However, many companies face challenges in adopting these advanced technologies. Not all industries have the same readiness for automation.

Sustainability is another focal point. A report by Smithers shows that eco-friendly packaging will grow by 15% annually. Innovative materials are being developed. Yet, not every company is prepared to make the shift. Some are still hesitant to embrace sustainable practices fully. They are cautious about costs and impacts on production lines.

Integrating AI in packaging processes is on the rise. This technology allows for real-time adjustments and predictive maintenance. Still, there is a learning curve. Many workers need retraining to adapt. The changes can create temporary disruptions. Future trends indicate that embracing these innovations will be crucial. However, the path involves complex decisions and potential setbacks.

Related Posts

-

Revolutionizing Supply Chains: The Future of Industrial Packaging Equipment Explained

-

Top 5 Custom Packaging Machine Trends Driving Efficiency and Growth in 2023

-

Top Tips for Choosing Packaging Equipment Systems for Your Business?

-

Revolutionizing the Food Industry How Food Packaging Machines Enhance Freshness and Sustainability

-

Revolutionizing Efficiency: How Automated Packaging Machines Transform Your Production Line

-

10 Best Custom Packaging Machines for Your Business Needs