Revolutionizing Supply Chains: The Future of Industrial Packaging Equipment Explained

In today's rapidly evolving industrial landscape, the role of industrial packaging equipment has never been more critical to supply chain efficiency and sustainability. According to a recent report from MarketsandMarkets, the global industrial packaging market is projected to reach USD 312.5 billion by 2025, growing at a CAGR of 5.2%. This growth is driven by rising demand for safe and efficient transport of goods in industries such as food and beverage, pharmaceuticals, and electronics. As companies strive to optimize their logistics and reduce waste, the integration of advanced packaging technologies has emerged as a key focus area.

From automation to innovative materials, the future of industrial packaging equipment is centered around enhancing supply chain performance while minimizing environmental impact. Industry experts report that automation in packaging processes can lead to a 20-25% increase in productivity. Moreover, the adoption of smart packaging solutions, which utilize IoT and data analytics, allows for real-time monitoring and improved traceability, thereby ensuring compliance and reducing losses. As we delve into the transformative trends shaping the future of industrial packaging equipment, it becomes clear that companies that adapt to these innovations will not only streamline their operations but also gain a competitive edge in the market.

Emerging Technologies Shaping the Future of Industrial Packaging Equipment

The future of industrial packaging equipment is being reshaped significantly by emerging technologies such as artificial intelligence (AI), advanced computing, and automation. According to recent industry studies, AI is revolutionizing various aspects of the packaging process, from design to distribution. It is estimated that AI-driven solutions can reduce material waste by up to 30%, enhancing sustainability efforts across the supply chain. This shift towards data-driven packaging solutions not only optimizes resource usage but also aligns with global trends emphasizing eco-friendliness.

Furthermore, innovations like Flexible Organic Photonic Layer Packaging (FOPLP) and Co-Packaged Optics (CPO) are setting new benchmarks in packaging efficiency. The semiconductor industry's growth, propelled by a demand surge for AI and advanced technologies, is forecasted to reach a valuation of over $500 billion by 2025. This growth is expected to contribute to advancements in back-end packaging and testing processes, highlighting the interdependent relationship between semiconductor technology and packaging innovations. As businesses adapt to these rapidly evolving technologies, the landscape of industrial packaging is poised for transformative changes that prioritize both performance and sustainability.

Revolutionizing Supply Chains: The Future of Industrial Packaging Equipment Explained

| Technology | Description | Impact on Supply Chain | Future Trends |

|---|---|---|---|

| Automation | Use of automated systems for packaging processes. | Increases efficiency and reduces labor costs. | Greater adoption in warehouses and production lines. |

| IoT Integration | Devices connected to the internet for real-time tracking. | Improves visibility across the supply chain. | Enhanced data analytics and predictive maintenance. |

| Sustainable Materials | Use of biodegradable or recyclable packaging materials. | Reduces environmental impact and aligns with consumer preferences. | Increase in regulatory pressures and consumer demand for sustainability. |

| Smart Packaging | Packaging that can communicate information about goods. | Enhances user experience and safety in transit. | Growth in smart labels and sensors for tracking conditions. |

| Robotics | Use of robotic systems for packaging and material handling. | Increases speed and accuracy in packaging processes. | Advances in AI and machine learning improving efficiency. |

Sustainable Practices in Supply Chain and Packaging Solutions

The demand for sustainable practices within supply chains and packaging solutions is shaping the future of the industrial packaging equipment industry. A significant driver for this transformation is the increasing awareness of environmental concerns and the need for eco-friendly materials. In particular, the medical and packaging sectors are experiencing a surge in demand for renewable resources, such as organic cotton, which not only offers health benefits like UV protection but also possesses antibacterial properties, making it an ideal choice for packaging and medical applications.

Recent discussions at industry forums, such as the 2025 China Packaging Innovation Forum, have highlighted the commitment of companies to create sustainable ecosystems. With aims to achieve a zero carbon footprint by 2030, many organizations are adopting low-carbon innovations in their packaging processes. Reports indicate that the sustainable regenerated fiber market is anticipated to reach substantial valuations, driven by the increasing preference for environmentally friendly materials. The transition towards sustainable packaging not only addresses environmental impacts but also enhances brand reputation, offering a dual benefit of profitability and ecological responsibility.

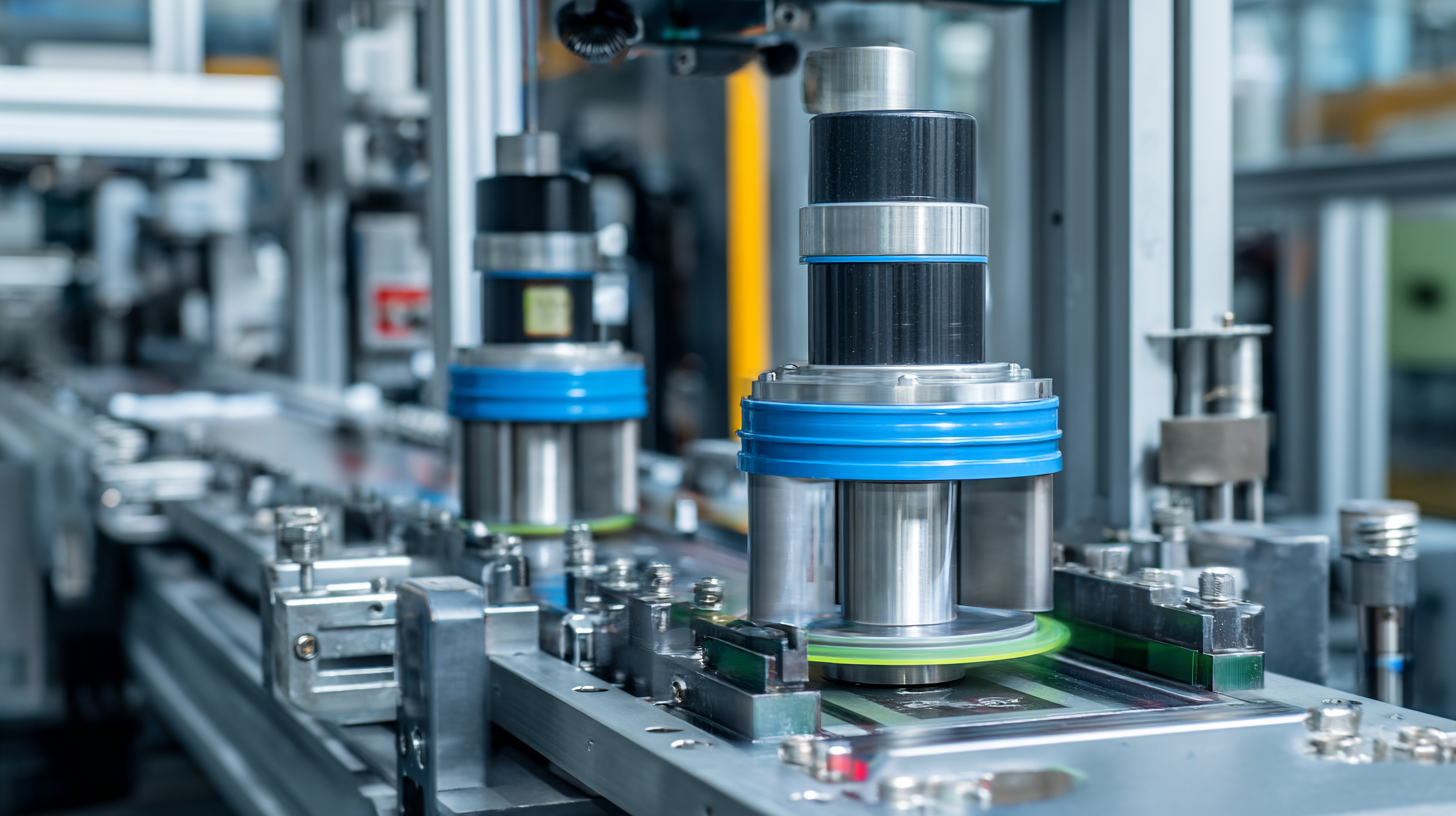

Integrating Automation for Enhanced Efficiency in Packaging Operations

The integration of automation within industrial packaging operations is rapidly transforming supply chains, leading to enhanced efficiency and productivity. According to a report by the Automation Federation, automated packaging solutions can increase production speed by up to 50%, which is critical in an era where consumer demands are rapidly evolving. This shift not only streamlines the packaging process but also minimizes human error, resulting in higher-quality outputs and reduced waste.

Moreover, advancements in robotics and artificial intelligence are reshaping the landscape of packaging equipment. A study from Smithers Pira highlights that the market for automated packaging machinery is expected to grow at a compound annual growth rate (CAGR) of 7.5% through 2025. This surge can be attributed to the need for more flexible, efficient, and data-driven operations, enabling businesses to adapt quickly to market changes. By leveraging automation, companies can optimize their supply chains, ensuring timely delivery and meeting the growing expectations of customers while also significantly cutting operational costs.

Revolutionizing Supply Chains: Automation Impact on Packaging Efficiency

This chart illustrates the projected increase in efficiency due to automation integration within industrial packaging operations over the years from 2020 to 2025. The data reflects a significant upward trend, showcasing the potential benefits of adopting advanced packaging technologies.

The Role of Data Analytics in Optimizing Packaging Decisions

The integration of data analytics into industrial packaging is transforming supply chains and enabling businesses to make more informed packaging decisions. According to Gartner's 2020 predictions on data and analytics technologies, enhanced analytics and machine learning will be pivotal in determining the most efficient packaging options. Companies leveraging these technologies can expect to see substantial cost reductions, with some studies estimating savings of up to 30% in packaging materials and logistics through better data utilization.

Moreover, the adoption of natural language processing and conversational analytics allows businesses to extract insights from their data more effectively, helping them to anticipate market trends and consumer behaviors. With these insights, packaging decisions can be tailored not just to logistical needs but also to align with sustainability goals, thus appealing to a growing base of eco-conscious consumers.

Moreover, technologies like blockchain can offer traceability and transparency, further optimizing supply chain processes. As data-driven decision-making becomes the norm, those in the industrial packaging sector must harness these advancements to stay competitive.

Innovative Materials Transforming the Industrial Packaging Landscape

The industrial packaging sector is undergoing a significant transformation, driven mainly by innovative materials that are reshaping the landscape. According to a report by Smithers Pira, the global market for industrial packaging is projected to reach $1 trillion by 2024, with a notable shift towards sustainable and advanced material solutions. Companies are now investing heavily in biodegradable plastics and recycled materials, which cater to the growing consumer demand for eco-friendly options.

For instance, the adoption of biodegradable films made from renewable resources has increased by 30% over the past three years, as businesses prioritize sustainability in their operations.

Additionally, advancements in smart packaging technologies are revolutionizing how goods are transported and stored. The introduction of materials embedded with sensors and RFID tags not only enhances supply chain transparency but also reduces waste. The Freedonia Group reported that the demand for smart packaging is expected to grow at an annual rate of 6.5%, emphasizing its critical role in the future of industrial packaging solutions. As these innovative materials gain traction, they promise to improve efficiency, reduce costs, and significantly lower the environmental impact of industrial packaging.

Related Posts

-

Revolutionizing the Food Industry How Food Packaging Machines Enhance Freshness and Sustainability

-

Innovative Material Handling Carts for Efficient Workplace Organization and Productivity

-

Exploring the Future of Conveyor Systems in Automation and Smart Manufacturing

-

Revolutionizing Efficiency: How Automated Packaging Machines Transform Your Production Line

-

The Essential Guide to Choosing the Best Material Handling Carts for Your Business Needs

-

Mastering Efficiency: How VFFS Machines Revolutionize Packaging Processes for Modern Businesses