Top Bottle Filling Machine Options for Your Business Needs?

The demand for efficient packaging solutions is growing rapidly. According to a recent market report, the global bottle filling machine market is projected to reach USD 6 billion by 2025, growing at a CAGR of 5.6%. This trend highlights the need for businesses to invest in reliable bottle filling machines. These machines not only enhance productivity but also improve accuracy in filling.

Many companies often struggle to choose the right machine that fits their specific needs. From small startups to large-scale manufacturers, selecting the appropriate bottle filling machine can be daunting. It’s crucial to consider factors like speed, compatibility, and automation potential. Each option comes with its pros and cons, which requires careful reflection and research.

Additionally, businesses should not overlook the importance of machine maintenance and support. A well-functioning bottle filling machine can significantly reduce operational downtime. However, neglecting routine checks can lead to costly repairs and inefficiencies. Understanding these aspects is vital for making an informed decision in the competitive market.

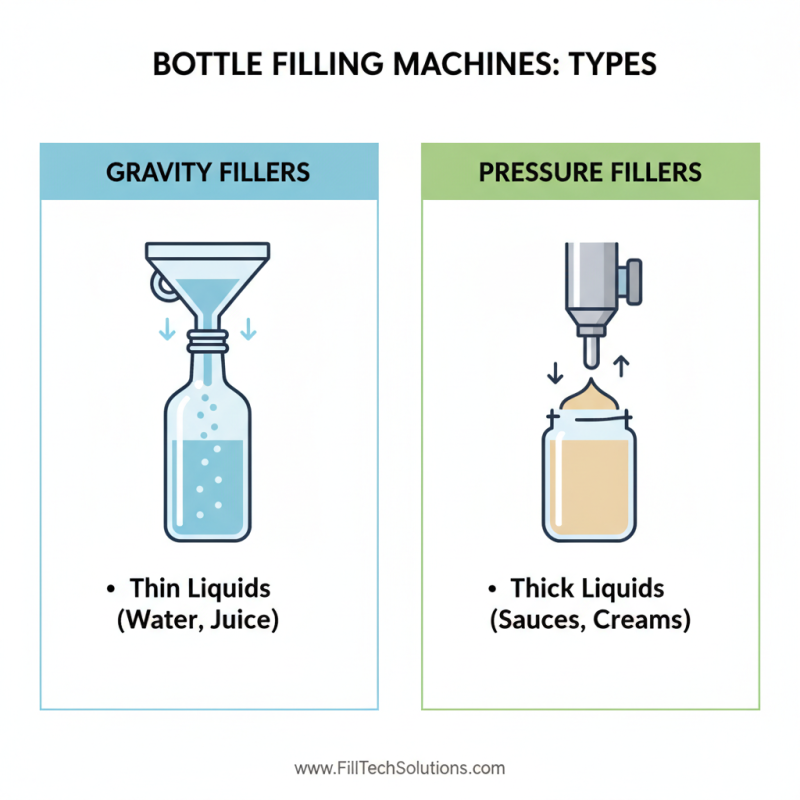

Types of Bottle Filling Machines Available in the Market

When exploring bottle filling machines, it’s essential to understand the types available. Each type serves different needs. For example, gravity fillers rely on the force of gravity. They are often used for thin liquids. Pressure fillers, on the other hand, are suitable for thick liquids and pastes.

Tips: Always consider the viscosity of your product. A mismatch can lead to spills and wastage.

Piston fillers are versatile. They can handle varying liquid densities and are ideal for both small and large batches. Volumetric fillers offer precision, making them great for consistent filling. However, they may require frequent calibration.

Tips: Regular maintenance is key. Check seals and hoses periodically to avoid downtime.

Choosing the right machine also depends on your production scale. Manual machines are cost-effective for small businesses. Automated options are excellent for high-volume production but come with higher costs. It’s important to evaluate your production demands to avoid overinvestment.

Key Features to Consider When Choosing a Bottle Filling Machine

When selecting a bottle filling machine, several key features are vital for ensuring efficiency and quality. One major consideration is the machine's filling speed. According to industry reports, high-speed machines can fill up to 600 bottles per minute. This is crucial for businesses with high volume demands. However, it's essential to balance speed with accuracy to avoid costly overfills or underfills.

Another important aspect is the machine's versatility. Some machines handle various bottle sizes and shapes. This flexibility aids businesses as they expand their product lines. A single machine that adapts to different bottles can save time and resources. Reports indicate that companies that invest in versatile equipment can increase production efficiency by 30% on average.

It's also critical to consider ease of cleaning and maintenance. Machines that are simple to disassemble reduce downtime significantly. Many machines lack user-friendly design, leading to extended maintenance periods. Regularly scheduled maintenance is often overlooked, potentially jeopardizing production schedules. Investing in technology that simplifies these processes can lead to better operational efficiency and lower long-term costs.

Benefits of Automated Bottle Filling Machines for Business Efficiency

Automated bottle filling machines offer numerous benefits, enhancing business efficiency. They save times and improve accuracy. With precise filling, businesses reduce waste and maximize resources. This leads to higher profit margins. Manual filling, on the other hand, often results in inconsistencies. Automation helps eliminate human error, ensuring every bottle is filled correctly.

When considering the right machine, think about your specific needs. Evaluate the volume you expect to handle. Think about the types of bottles you’ll use. Matching the machine to your product line is vital. Look for machines that are easy to clean and maintain. Simplicity matters—complex setups can lead to downtime.

A tip: assess your workspace before purchasing. Ensure you have adequate space for installation and operation. Customer feedback is crucial as well. Reach out to other businesses in your industry. Learn about their experiences with different machines. Adjustments may be necessary after initial use. Reflecting on performance will help improve efficiency. Always stay open to optimizing your process.

Factors Affecting the Cost of Bottle Filling Machines

When selecting a bottle filling machine, cost is a key factor. Prices vary significantly based on several elements. According to industry reports, basic machines can start at around $5,000. High-speed, automated models may exceed $100,000. Understanding what influences these costs is crucial for business budgeting.

The level of automation is one major factor. Manual machines are typically cheaper. However, they require more labor. In contrast, semi-automated and fully automated systems offer efficiency. They reduce labor costs over time but demand a larger initial investment. Furthermore, production speed also impacts pricing. Machines with higher throughput capabilities usually entail higher costs.

Material quality also plays a role. Stainless steel machines are durable but costly. Polished finishes add to the price. Maintenance needs are another consideration. More complicated systems can lead to increased maintenance costs. By analyzing these factors, businesses can make informed decisions. Choosing the right bottle filling machine involves balancing upfront costs and long-term efficiency.

Top Bottle Filling Machine Options for Your Business Needs

Maintenance Tips for Maximizing the Lifespan of Bottle Filling Machines

Proper maintenance of bottle filling machines can significantly enhance their lifespan. According to industry reports, regular maintenance can prolong machine performance by up to 30%. Ensuring that components are clean and functioning optimally minimizes wear and tear. This is essential in maintaining efficiency and reducing downtime, which can cost businesses substantially.

One effective tip is to schedule routine inspections. Ensure that all parts, especially seals and pumps, are regularly checked and replaced if necessary. Neglecting small issues can lead to larger malfunctions. Additionally, lubricating moving parts keeps operations smooth. Even a small amount of grit or grime can affect performance. A well-maintained machine is less likely to break down unexpectedly.

Another tip involves using the right cleaning agents. Harsh chemicals can corrode internal components and decrease a machine's lifespan. Instead, opt for milder, machine-specific cleaners. Keeping surfaces dry can also help prevent rust. Businesses should document maintenance records, tracking performance trends and identifying potential issues early. Adapting these simple steps could improve overall efficiency and protect your investment.

Related Posts

-

10 Essential Tips for Choosing the Right Bottle Filling Machine

-

2025 Top Filling Machine Innovations Enhancing Efficiency and Precision in Manufacturing

-

Why Industrial Packaging Equipment is Essential for Modern Business Success?

-

What is Automated Packaging Equipment and Its Benefits?

-

2026 How to Choose the Right Small Conveyor Belt for Your Needs?

-

What is a Belt Conveyor and How Does it Work in Material Handling