Top 10 Food Packaging Equipment Every Business Should Consider in 2023

In the rapidly evolving landscape of the food industry, the importance of efficient and reliable food packaging equipment cannot be overstated. As we move further into 2023, businesses must adapt to new consumer demands and sustainability standards, making the choice of packaging equipment more critical than ever. Renowned expert in food processing, Dr. Emily Stanton, emphasizes the significance of this transition, stating, "The right food packaging equipment not only enhances product freshness but also plays a pivotal role in brand identity and customer trust."

The integration of innovative packaging solutions allows companies to streamline their operations, improve shelf life, and reduce waste. With an increasingly competitive market, selecting the ideal food packaging equipment is key to maintaining a competitive edge. From automated systems that enhance efficiency to eco-friendly solutions that meet consumer expectations, the choices are vast and varied. As we delve into the top 10 food packaging equipment that every business should consider this year, it is essential to recognize how these tools can empower businesses to thrive in an ever-changing economic environment.

Types of Food Packaging Equipment Essential for Businesses

In the competitive food industry, having the right packaging equipment is crucial for ensuring product quality and operational efficiency. As of 2023, several types of food packaging equipment stand out as essential for businesses looking to enhance their packaging processes. According to a report by Future Market Insights, the global food packaging machinery market is expected to reach $45 billion by 2026, driven by increasing demand for conveniently packaged foods and the growth of e-commerce.

Among the fundamental types of food packaging equipment are vacuum sealers and filling machines. Vacuum sealers are vital for extending the shelf life of perishable goods by removing air from packages, which helps to prevent spoilage and maintain freshness. Additionally, filling machines enable businesses to automate the packing process, ensuring speed and consistency while reducing labor costs. With advancements in technology, businesses can now opt for versatile filling machines that accommodate various product types, making them a great investment as reported by Grand View Research, which emphasizes the importance of automation in the current market landscape.

Another critical equipment category is labeling machines, which play a significant role in branding and compliance with regulatory standards. Accurate labeling not only informs consumers about product contents but also enhances brand identity. A study by the Food and Beverage Industry Association indicates that up to 70% of purchasing decisions are influenced by packaging design, highlighting the necessity for effective labeling systems that keep up with consumer preferences and regulatory requirements. Investing in these key types of packaging equipment will not only streamline production but also enhance customer satisfaction and brand loyalty in a rapidly evolving market.

Key Features to Look for in Food Packaging Machinery

When selecting food packaging machinery, it's essential to consider key features that can significantly enhance efficiency and sustainability.

One of the most crucial aspects is automation. Automated packaging systems reduce labor costs and increase production speed, allowing businesses to meet high demand without compromising on quality. In today's fast-paced market, investing in machinery that offers seamless integration with existing processes can streamline operations and improve overall productivity.

Another vital feature is versatility. Food packaging equipment should adapt to various products, whether dry, liquid, or semi-solid. This flexibility allows businesses to diversify their offerings without the need for multiple machines, ultimately saving space and costs. Additionally, consider machinery that supports different packaging styles, such as vacuum sealing, shrink wrapping, or modified atmosphere packaging, to cater to changing consumer preferences.

Tip: Before committing to a machine, evaluate its maintenance requirements and overall durability. Long-lasting equipment minimizes downtime and maintenance costs, ensuring smoother operations. Additionally, look for user-friendly interfaces that reduce training time for staff.

Tip: Sustainability is becoming increasingly critical; therefore, choose equipment that uses eco-friendly materials and energy-efficient processes. This not only appeals to environmentally-conscious consumers but also aligns with global trends towards reducing carbon footprints in food production.

Benefits of Investing in Modern Food Packaging Solutions

Investing in modern food packaging solutions is essential for businesses aiming to enhance efficiency, maintain product quality, and meet evolving consumer demands. One of the primary benefits of advanced packaging technologies is improved shelf life and freshness. Innovative materials and technologies can create airtight seals and protective atmospheres that significantly extend the longevity of perishable goods. This not only reduces waste but also ensures that consumers receive products in optimal condition, which can greatly enhance brand reputation and customer satisfaction.

Moreover, modern packaging equipment often incorporates automation, which increases operational efficiency and reduces labor costs. By streamlining production processes, businesses can achieve higher output rates and minimize the risk of human error. Automated processes also allow for a more consistent packaging quality, which is crucial for maintaining brand standards. Going beyond efficiency, modern packaging solutions can also adapt to meet sustainability goals. Eco-friendly materials and energy-efficient machinery not only appeal to environmentally conscious consumers but also position businesses as responsible and modern players in the marketplace, driving brand loyalty and competitive advantage.

Top 10 Food Packaging Equipment Every Business Should Consider in 2023 - Benefits of Investing in Modern Food Packaging Solutions

| Equipment Type | Description | Benefits | Estimated Cost |

|---|---|---|---|

| Vacuum Packaging Machine | Removes air from packaging to extend shelf life. | Reduces spoilage, saves costs on waste. | $1,500 - $5,000 |

| Filling Machine | Fills packaging with various types of food products. | Increases efficiency and minimizes waste. | $10,000 - $100,000 |

| Labeling Machine | Applies labels to food packaging automatically. | Enhances branding and compliance with regulations. | $5,000 - $30,000 |

| Sealing Machine | Seals pouches or containers to keep products fresh. | Prevents contamination and prolongs shelf life. | $2,000 - $15,000 |

| Shrink Wrapping Machine | Shrinks plastic around products for protection. | Enhances product visibility and tamper evidence. | $8,000 - $40,000 |

| Blister Packaging Machine | Forms blisters for products like pills or snacks. | Provides tamper-proof packaging and durability. | $20,000 - $70,000 |

| Cup Filling Machine | Fills and seals cups with various liquid or semi-liquid foods. | Speeds up production and improves sanitation. | $10,000 - $60,000 |

| Horizontal Flow Wrapper | Wraps products in flexible film. | Maintains freshness and provides shelf visibility. | $15,000 - $100,000 |

| Automation Software | Controls packaging machinery for efficient operation. | Reduces labor costs and increases production speed. | $5,000 - $20,000 |

| Checkweigher | Ensures product weight accuracy in packaging. | Prevents legal issues and maintains customer satisfaction. | $7,000 - $30,000 |

Top Brands in Food Packaging Equipment for 2023

In 2023, the food packaging equipment industry is more dynamic than ever, driven by advancements in technology and an increased focus on sustainability. A report by MarketsandMarkets estimates that the global food packaging equipment market will reach USD 50.78 billion by 2025, growing at a CAGR of 4.10% between 2020 and 2025. This growth is largely attributed to the rising demand for convenience foods, which requires innovative packaging solutions that ensure product safety and extend shelf life.

Leading brands in the food packaging equipment sector are increasingly emphasizing automation and smart technology to enhance operational efficiency. According to a recent industry survey, over 70% of manufacturers are investing in automated packaging solutions to meet the rising volume of production and to reduce labor costs. Moreover, eco-friendly packaging options are gaining traction, with 35% of companies prioritizing materials that are biodegradable or recyclable. This shift not only addresses consumer preferences for sustainable packaging but also aligns with global initiatives to reduce plastic waste.

The growth trajectory of the food packaging equipment market highlights the importance of selecting the right technology and processes to stay competitive. Companies that adapt to new packaging trends, such as vacuum sealing, modified atmosphere packaging (MAP), and sustainable materials, are likely to outperform their peers. As the industry evolves, these factors will be crucial for businesses aiming to meet the changing demands of consumers while ensuring compliance with regulatory standards.

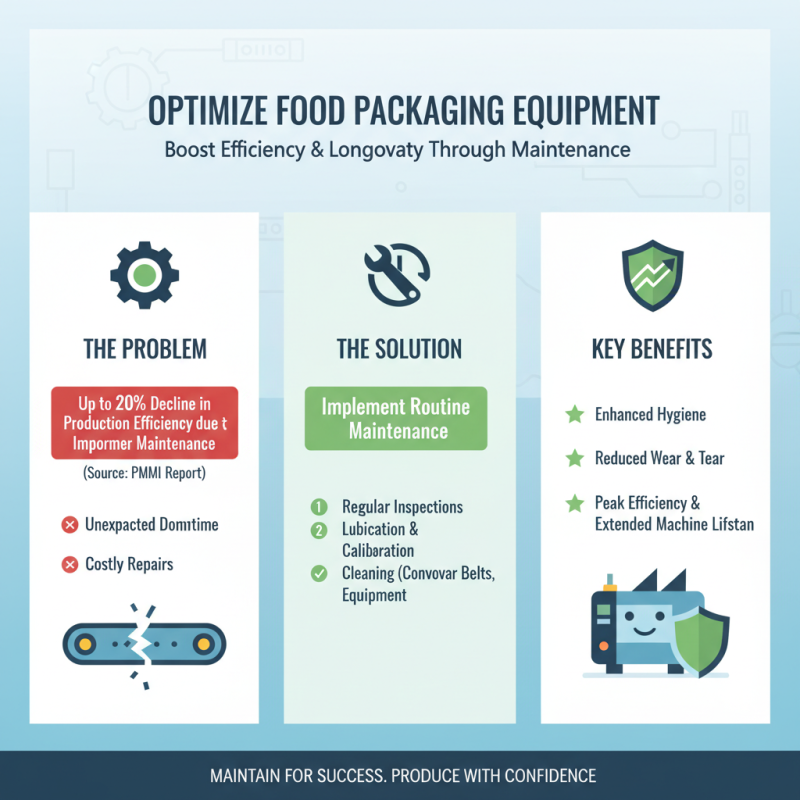

Maintenance Tips for Maximizing the Lifespan of Packaging Machines

Maintaining food packaging equipment is crucial for optimizing performance and extending the longevity of these essential machines. According to a report by the Packaging Machinery Manufacturers Institute (PMMI), improper maintenance can lead to a decline in production efficiency by up to 20%. Therefore, implementing a routine maintenance schedule is vital. Regular inspections, lubrication, and calibration help ensure that machines operate at peak efficiency and reduce the risk of unexpected downtimes. For instance, cleaning conveyor belts and sealing equipment not only enhances hygiene but also significantly minimizes wear and tear, which can result in costly repairs.

Moreover, training staff on best practices for handling and maintaining equipment can drastically improve performance levels. The Food and Drug Administration (FDA) emphasizes that proper employee training not only ensures compliance with health regulations but can lead to a 30% reduction in operational errors. Utilizing automated systems equipped with monitoring features can also aid in predictive maintenance, allowing businesses to anticipate failures before they occur. With the food packaging equipment market expected to reach $54 billion by 2027, ensuring that these investments are well-maintained is critical for any business aiming for sustainable growth in a competitive landscape.

Related Posts

-

Top 10 Packaging Automation Equipment for Streamlining Your Production Process

-

Top 5 Custom Packaging Machine Trends Driving Efficiency and Growth in 2023

-

2025 Top 5 Food Packaging Machines Transforming the Industry

-

Exploring the Future of Conveyor Systems in Automation and Smart Manufacturing

-

Revolutionizing Efficiency: How Automated Packaging Machines Transform Your Production Line

-

Revolutionizing Packaging: How Automatic Bagging Machines Enhance Efficiency and Precision in Industries