Top 10 Food Packaging Machines for Your Business Needs?

In today’s competitive market, finding the right food packaging machine is crucial. A reliable machine can streamline operations and protect products. It helps maintain freshness, boosts shelf life, and enhances branding. With so many options available, making a choice can be overwhelming.

Different businesses have unique needs. A small café may require a compact machine, while a large factory demands a high-capacity option. Understanding these specifics is vital. Choosing poorly can result in wasted resources and lost opportunities. Each food packaging machine has strengths and weaknesses.

Investing in the right packaging technology can transform your business. Quality machines offer efficiency. They can reduce labor costs and improve consistency. While it’s tempting to focus solely on price, consider longevity and reliability too. A machine is not just an expense; it’s an investment.

Top 10 Food Packaging Machines for Enhanced Efficiency and Safety

Efficient food packaging is crucial for any business. Modern food packaging machines play a significant role in improving efficiency and safety. According to a recent market report, the food packaging machinery sector is projected to grow at a compound annual growth rate of 4.5% from 2022 to 2030. This growth highlights the increasing need for innovative solutions in food processing.

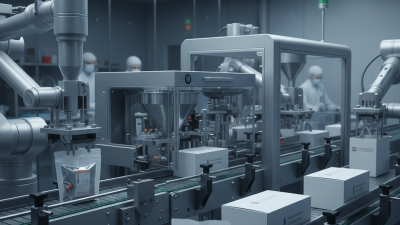

Automation in packaging helps reduce human error. Automated systems can handle the packaging process with precision. This reduces waste and improves consistency. Operators often struggle to maintain speed and accuracy during busy hours. Machine assistance can mitigate these issues. Additionally, enhanced safety features in modern machines minimize contamination risks. Some machines offer hygiene management systems, which are essential in maintaining food safety standards.

Investing in advanced technology can be expensive. However, the initial cost can be justified by the long-term gains. Reduced labor costs and waste can lead to significant savings. Yet, not all companies are ready for this transition. Some might find the complexity daunting. Training staff can be a challenge. Businesses must weigh the benefits against such issues. Careful consideration is necessary when selecting the right equipment.

Top 10 Food Packaging Machines for Enhanced Efficiency and Safety

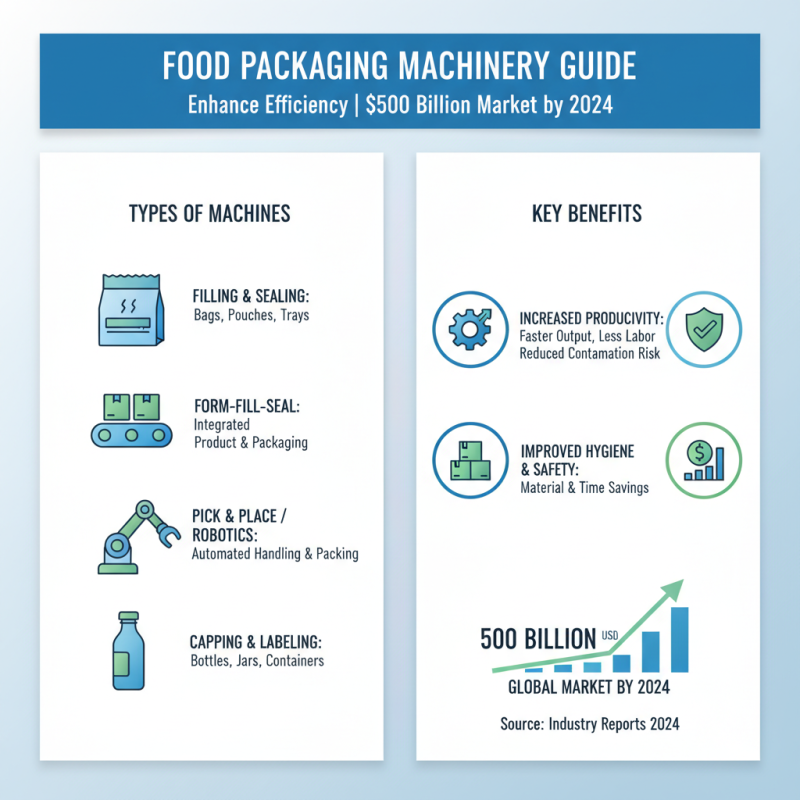

Understanding the Types of Food Packaging Machines: A Comprehensive Guide

Understanding the types of food packaging machines is crucial for businesses aiming to enhance efficiency. The food packaging market is expected to reach $500 billion by 2024, according to industry reports. This growth emphasizes the need for reliable and versatile packaging solutions.

There are several types of food packaging machines. For example, vacuum packers remove air to extend shelf life. These machines can boost preservation by up to 50%. Another type is the form-fill-seal machine, which can be customized for varied products. However, companies often face challenges. New machinery can be expensive, and selecting the right type can be confusing.

Effective packaging also requires quality control. Statistics show that 30% of packaged food gets wasted due to poor packaging. This poses a significant concern. Ensuring the right machinery and techniques directly impacts profits. It's not just about speed; it's about maintaining product integrity while minimizing waste. Balancing cost and quality remains a persistent issue for many businesses.

Key Features to Consider When Choosing Food Packaging Equipment

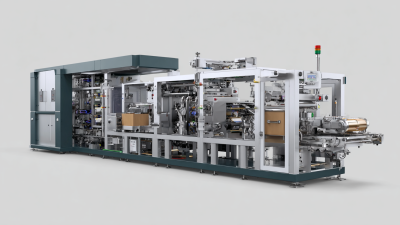

When selecting food packaging machines, certain features are essential. A well-designed machine should increase efficiency and maintain product integrity. Look for models with adjustable settings to accommodate various package sizes. Flexible packaging solutions can boost productivity by up to 30%, according to industry reports.

Consider automation features too. Machines with high-speed automation can significantly reduce labor costs. They help achieve a consistent output rate, minimizing human error. However, increased speed may compromise quality. Testing the machine’s performance on smaller batches is a smart move.

Tips: Always check for energy efficiency ratings. Machines consuming less energy can save costs over time. Additionally, ensure that the machine is easy to clean and maintain. This can prevent downtime and maintain hygiene standards.

Don’t overlook the importance of customer support. Reliable after-sales service can be a game changer. Critical feedback may surface when machines need adjustments or repairs. Investing time in research can lead to better choices.

Industry Trends: Automation in Food Packaging Solutions

As the food industry evolves, automation has become a key trend in food packaging. Companies are increasingly turning to automated solutions for enhanced efficiency. These machines can perform multiple tasks in a streamlined process. From filling to sealing, automation reduces human error and speeds up production. However, the initial investment can be daunting for small businesses.

Moreover, automation offers flexibility in packaging options. Customizable settings allow for different package sizes and styles. This adaptability helps businesses cater to a broader audience. Yet, the learning curve for staff can pose challenges. Employees need training to operate these advanced machines efficiently. Misunderstandings can lead to wasted materials or delays in production.

Sustainability is another area where automation plays a significant role. Machines can utilize eco-friendly materials and minimize waste. This shift towards green practices is not without its hurdles. Implementing sustainable solutions often requires significant changes to existing processes. Companies may face resistance or uncertainty about new methods. Balancing automation with sustainability will be a key focus in the future of the food packaging industry.

Top 10 Food Packaging Machines for Your Business Needs

| Machine Type | Speed (Units/Minute) | Suitable Packaging | Automation Level | Price Range (USD) |

|---|---|---|---|---|

| Vertical Form Fill Seal | 40 | Pouches, Bags | High | $20,000 - $50,000 |

| Horizontal Flow Wrapper | 120 | Trays, Bars | Medium | $25,000 - $60,000 |

| Cartoning Machine | 60 | Boxes, Cartons | High | $30,000 - $70,000 |

| Labeling Machine | 100 | Bottles, Jars | Medium | $15,000 - $40,000 |

| Shrink Wrapping Machine | 80 | Bundles, Pallets | High | $20,000 - $45,000 |

| Vacuum Packaging Machine | 30 | Meat, Cheese | Medium | $5,000 - $15,000 |

| Filling Machine | 50 | Liquids, Powders | High | $25,000 - $55,000 |

| Blister Packaging Machine | 40 | Tablets, Capsules | Medium | $10,000 - $30,000 |

| Cup Sealing Machine | 70 | Cups, Containers | High | $8,000 - $25,000 |

| Case Packing Machine | 75 | Cases, Packs | High | $35,000 - $80,000 |

Cost Analysis: Return on Investment for Food Packaging Machines

Investing in food packaging machines is crucial for businesses. The cost analysis should focus on the return on investment (ROI). An effective machine can streamline processes, but initial costs may be high. It's essential to weigh the benefits against these expenses.

Different machines serve various purposes. For example, some are designed for sealing, while others are for labeling. Each has its operational cost and potential savings. Analyzing the long-term costs is vital. A machine may seem expensive now, but it can save labor costs later.

Evaluate the downtime of machines. Frequent breakdowns can lead to lost revenue. Maintenance costs can add to the total expenses. Consider the lifespan of each machine. Investing in quality equipment could lead to better ROI. Reflect on whether the machine fits your production levels. It's not just about buying the latest model. It's about finding the right fit for your needs.

Related Posts

-

Top 10 Automated Packaging Machines You Need to Know About in 2023

-

2025 How to Choose the Best Automatic Packaging Machines for Your Business

-

What is Automated Packaging Equipment and Its Benefits?

-

Revolutionizing the Food Industry How Food Packaging Machines Enhance Freshness and Sustainability

-

Top 10 Custom Packaging Machines to Boost Your Business Efficiency in 2023

-

Top 5 Benefits of Using an Automated Packaging Machine for Your Business