2025 Top 5 Food Packaging Machines Transforming the Industry

In an era of rapid technological advancement, the food packaging machine industry is on the brink of transformation. By 2025, significant innovations are poised to redefine how food is packaged, enhancing efficiency, sustainability, and consumer appeal. Industry expert, Dr. Emily Ramirez, a leading figure in food engineering, emphasizes the need for such innovations in addressing both production challenges and environmental concerns. She states, "The future of food packaging machines lies in their ability to not only perform but also to adapt to the evolving needs of sustainability and safety in food supply chains."

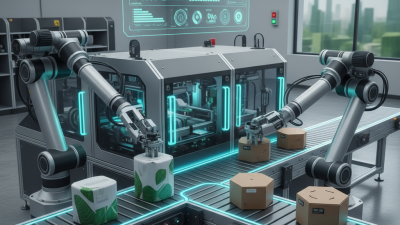

As we delve into the top five food packaging machines set to revolutionize the industry, it is essential to explore the advancements and features that these machines bring to the table. From automated processes that minimize human error to eco-friendly materials that reduce environmental impact, these innovations not only promise to enhance productivity but also align with the growing demand for sustainable practices in food production. The trajectory towards 2025 invites us to consider how these machines will shape the future of food packaging, ultimately influencing consumer choices and the global market.

Innovative Trends in Food Packaging Machinery for 2025

The food packaging industry is poised for a significant transformation in 2025, driven by innovative trends that prioritize sustainability and efficiency. One of the most prominent trends is the rise of smart packaging technologies, incorporating sensors and IoT capabilities. These advancements allow manufacturers to monitor freshness and provide consumers with real-time product information, thereby enhancing safety and reducing food waste. As consumers increasingly demand transparency, smart packaging can bridge the gap by offering detailed insights into ingredient sourcing and product lifecycle.

Another key trend is the implementation of eco-friendly packaging materials. With growing awareness of environmental issues, companies are turning to biodegradable and recyclable materials that minimize their carbon footprint. Advances in bioplastics and edible packaging are leading the way, offering alternatives that are both functional and sustainable. Additionally, automation in packaging processes is set to streamline production, reduce labor costs, and increase speed. Together, these innovations are not only transforming how food is packaged but are also setting new industry standards for safety, sustainability, and consumer engagement.

Sustainability: Eco-Friendly Solutions in Modern Food Packaging

In today's food packaging industry, sustainability has become a crucial focus as companies strive to reduce their environmental impact. Innovative eco-friendly solutions are emerging, such as biodegradable materials and recyclable packaging, which not only help in conserving resources but also appeal to environmentally conscious consumers. With advancements in technology, manufacturers are now able to produce high-quality packaging that minimizes waste while maintaining product freshness.

**Tips for Choosing Sustainable Packaging:**

1. Look for certifications such as FSC or Cradle to Cradle that ensure the materials are sourced responsibly.

2. Opt for packaging that uses minimal ink and dyes to reduce environmental footprint during the production process.

3. Consider reusable packaging options to lessen single-use plastic waste and promote a circular economy.

As the industry moves forward, integrating sustainable practices into food packaging design will not only enhance brand reputation but also cater to the growing demand for eco-friendly products. Companies that embrace these innovations are setting themselves apart in a competitive market, aligning profitability with responsibility.

Automation and Robotics: Enhancing Packaging Efficiency

In an era where efficiency is key to business success, the food packaging industry is witnessing a significant transformation fueled by automation and robotics. The 2023 Packaging Industry Report highlights that nearly 70% of food manufacturers are investing in automated packaging solutions to enhance efficiency and reduce labor costs. Automated systems can dramatically accelerate the packaging process, with studies showing that they can increase productivity by up to 30%. As consumer demands for quicker service and fresher products rise, the integration of these technologies is becoming essential.

Robotics in food packaging also ensures greater accuracy and consistency, minimizing the risk of human error. Data from Smithers Pira indicates that smart packaging systems are anticipated to account for more than 25% of the market by 2025, driven by the need for precision in packaging operations. With robots capable of handling a diverse range of products, from fragile items to bulk packages, manufacturers are able to streamline operations while maintaining high safety and hygiene standards. This trend not only enhances productivity but also supports sustainability goals by optimizing material usage and reducing waste in the packaging process.

2025 Top 5 Food Packaging Machines Transforming the Industry

Smart Technology: IoT Integration in Food Packaging Machines

The integration of IoT technology into food packaging machines is a game changer for the industry, enabling smarter manufacturing processes that enhance efficiency, quality, and sustainability. As the global food processing and handling equipment market is projected to grow significantly, reaching nearly $190 billion by 2032, the role of advanced packaging machinery becomes increasingly critical.

Smart food packaging machines equipped with IoT capabilities allow for real-time monitoring and data analytics, providing manufacturers with valuable insights into production processes, inventory management, and consumer preferences.

This technological transformation is particularly vital in sectors like beverage production, where consistent processes are crucial. With automated solutions driven by IoT, companies can achieve improved operational efficiency while maintaining high-quality standards. Not only do these advancements streamline production lines, but they also contribute to sustainability efforts by optimizing resource usage and reducing waste.

As we move towards 2025, the emergence of intelligent packaging solutions will undoubtedly redefine manufacturing paradigms, making them more responsive and adaptable to evolving market demands.

Customizable Packaging Solutions: Meeting Diverse Consumer Demands

The food packaging industry is rapidly evolving to meet the diverse demands of modern consumers, emphasizing the need for customizable packaging solutions. According to a report by Fortune Business Insights, the global food packaging market is projected to reach $600 billion by 2025, growing at a CAGR of 5.8%. This growth underscores the importance of innovation in packaging technology that can adapt to various consumer preferences, such as sustainability, convenience, and aesthetic appeal.

Customizable packaging not only enhances product visibility but also aligns with consumers' growing expectations for personalized experiences. Research from the Packaging Innovation Study revealed that 45% of consumers are willing to pay more for products that feature unique packaging designs. Machines that offer flexible packaging formats enable food manufacturers to quickly respond to changing market trends and the rise of niche products. This shift towards tailored solutions fosters brand loyalty and meets the increasing demand for eco-friendly and functional packaging options, driven by millennials and Gen Z consumers who prioritize sustainability. As industry leaders leverage advanced food packaging machines, the future of packaging will increasingly focus on delivering customized, consumer-centered solutions.

Related Posts

-

Revolutionizing Efficiency: How Automated Packaging Machines Transform Your Production Line

-

10 Best Custom Packaging Machines for Your Business Needs

-

Top 10 Packaging Automation Equipment for Streamlining Your Production Process

-

Top 5 Custom Packaging Machine Trends Driving Efficiency and Growth in 2023

-

Revolutionizing Supply Chains: The Future of Industrial Packaging Equipment Explained

-

10 Best Industrial Packaging Equipment for Maximum Efficiency