Top Packaging Equipment Trends You Need to Know for Your Business

In the ever-evolving landscape of the manufacturing sector, keeping abreast of the latest trends in packaging equipment is crucial for businesses aiming to enhance efficiency, sustainability, and consumer appeal. According to industry expert Dr. Emily Carter, a leading authority in packaging technology, "The right packaging equipment not only streamlines the production process but also significantly impacts product viability and customer satisfaction." As companies adapt to changing consumer demands and environmental concerns, investing in innovative packaging solutions has never been more essential.

The trends in packaging equipment reflect broader shifts within the industry, such as the increased emphasis on automation, digitalization, and sustainable practices. Companies are increasingly turning to smart packaging systems that integrate advanced technologies like IoT and AI, allowing for real-time monitoring and optimization of the packaging process. By embracing these trends, businesses can not only improve their operational efficiency but also align their practices with customer expectations for eco-friendly products.

Furthermore, understanding these trends enables businesses to remain competitive in a saturated market. As Dr. Carter highlights, "Staying ahead in packaging innovation can set a brand apart, making its products more appealing and efficient." This outlook emphasizes the importance of being proactive in adopting cutting-edge packaging equipment to foster growth and sustainability in today’s dynamic business environment.

Emerging Technologies in Packaging Equipment for Modern Businesses

In today's fast-paced market, emerging technologies in packaging equipment are revolutionizing the way businesses operate. Innovations such as automated packing systems, smart sensors, and sustainable materials are enhancing efficiency and reducing waste. Companies are now able to track inventory in real time and predict maintenance needs, thereby minimizing downtime and improving overall productivity.

Tip: Consider investing in automated packaging solutions that integrate with your existing systems. This can streamline operations and provide you with valuable data to make informed decisions about your supply chain.

Furthermore, trends indicate a significant shift towards eco-friendly packaging. Businesses are increasingly adopting biodegradable and recyclable materials, responding to consumer demand for sustainability. This not only meets regulatory requirements but also enhances brand loyalty by aligning with environmentally conscious consumers.

Tip: Evaluate your current packaging materials and explore alternatives that offer sustainable options without compromising quality. This can improve your brand's image and attract a broader customer base.

Sustainability Practices in Packaging Equipment Design and Use

Sustainability is becoming an integral part of packaging equipment design and use, driven by growing consumer demand and regulatory pressures. Innovators in the packaging industry are focusing on reducing the environmental impact of their machinery and processes. This includes the use of recycled materials in equipment construction and the development of energy-efficient machines that consume less power during production. The emphasis on durability and longevity in equipment also plays a crucial role, ensuring that machines have a longer lifespan and require fewer resources for maintenance and replacement.

Moreover, many companies are adopting closed-loop systems that minimize waste throughout the packaging process. This involves designing equipment that not only packages products efficiently but also allows for the easy recycling or repurposing of materials. By integrating automated systems that track and manage resource usage, businesses can optimize their operational efficiency while adhering to sustainable practices. As these trends continue to evolve, companies that prioritize sustainability in their packaging equipment will not only comply with regulations but will also enhance their brand reputation and appeal to environmentally conscious consumers.

Top Packaging Equipment Trends: Sustainability Practices in Packaging Equipment Design and Use

Automation and Robotics: Revolutionizing Packaging Processes

Automation and robotics are at the forefront of transforming packaging processes, leading to significant improvements in efficiency and productivity. As businesses increasingly adopt automated solutions, traditional manual practices are evolving into streamlined operations that minimize human error and reduce labor costs. With the integration of advanced technologies such as machine learning and computer vision, robotic systems can now accurately pick, pack, and sort products with remarkable speed and precision. This shift not only enhances overall workflow in warehouses but also ensures faster fulfillment rates for online orders.

Moreover, the integration of robotics into supply chain management is driving a radical change in how businesses handle logistics. Robotics companies are continually innovating, developing machines that can adapt to various tasks and environments, effectively optimizing warehouse layouts and processes. For instance, automated robotic picking systems can significantly increase throughput while maintaining accuracy, responding dynamically to the fluctuating demands of e-commerce. As these technologies mature, they promise to create fully automated solutions that redefine productivity standards in packaging and fulfillment, offering businesses the chance to scale operations efficiently while meeting customer expectations.

The Role of IoT in Enhancing Packaging Equipment Efficiency

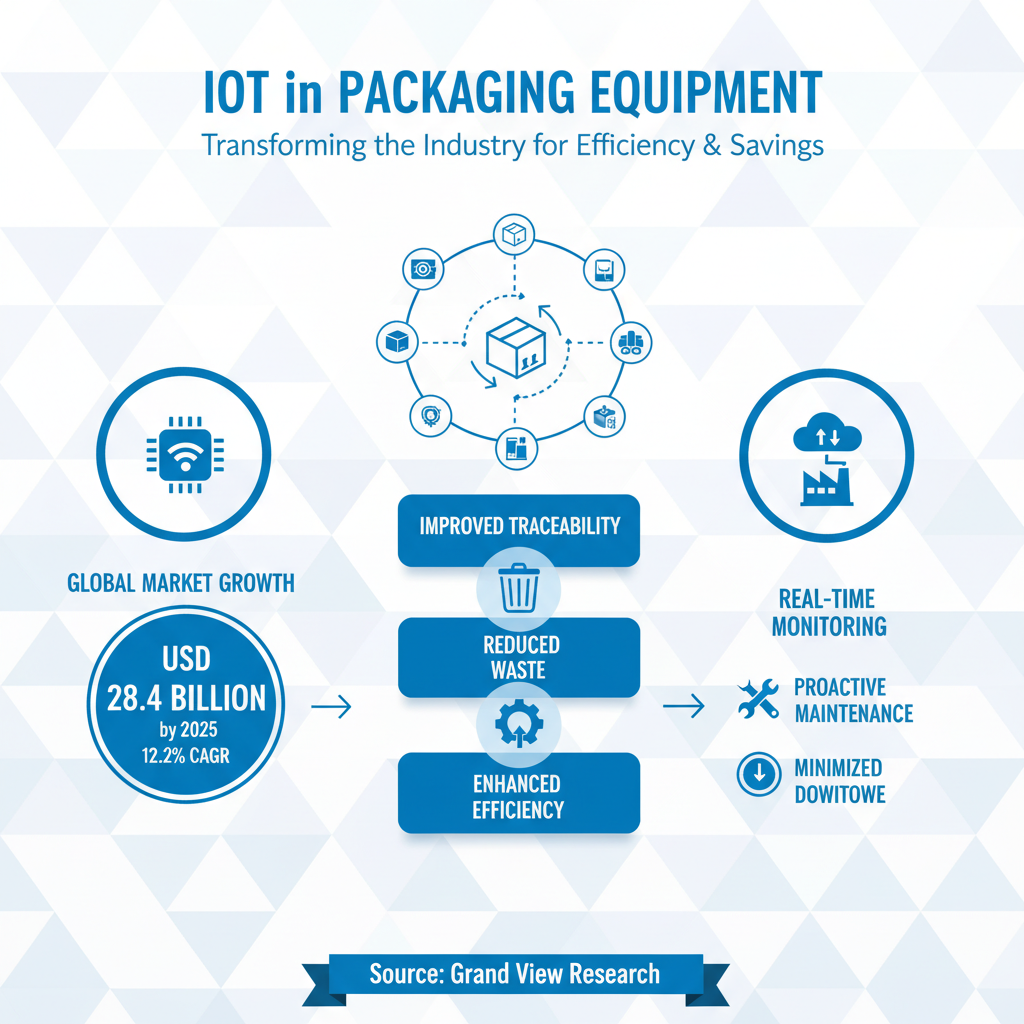

The integration of the Internet of Things (IoT) into packaging equipment is revolutionizing the industry by enhancing efficiency and reducing operational costs. According to a report by Grand View Research, the global IoT in packaging market size is expected to reach USD 28.4 billion by 2025, growing at a CAGR of 12.2%. This surge is primarily driven by the rising demand for smart packaging solutions that improve traceability and reduce waste. With IoT-enabled devices, companies can monitor their equipment in real-time, gaining insights into performance metrics that were previously inaccessible, allowing for proactive maintenance and minimizing downtime.

Moreover, the implementation of IoT technology in packaging lines is instrumental in optimizing production processes. A study published by the Packaging Machinery Manufacturers Institute (PMMI) found that nearly 70% of manufacturers are looking to leverage IoT to enhance their packaging operations. By utilizing connected sensors and data analytics, businesses can streamline workflows, increase output quality, and track supply chain status more effectively. This technological advancement not only enhances precision but also supports sustainability efforts, as companies can better manage resources and reduce their carbon footprint through improved efficiency and reduced waste.

Customizable Packaging Solutions: Meeting Diverse Consumer Needs

In today’s competitive marketplace, customizable packaging solutions are becoming essential in meeting the diverse needs of consumers. As preferences evolve rapidly, brands must adapt their packaging to reflect individuality and sustainability. Customizable options allow businesses to offer tailored experiences, from personalized designs to varied sizes and materials, enhancing customer engagement and satisfaction. This trend not only promotes brand loyalty but also appeals to environmentally conscious shoppers who prefer eco-friendly packaging alternatives.

Moreover, advancements in packaging technology facilitate the integration of customization. Companies can utilize digital printing and automated processes to create unique packaging solutions efficiently. This flexibility enables brands to respond quickly to market demands and consumer preferences, ensuring that they remain relevant in a fast-changing landscape. By investing in customizable packaging, businesses can differentiate themselves from competitors and create a memorable unboxing experience, fostering stronger connections with their audience.

Related Posts

-

Revolutionizing the Food Industry How Food Packaging Machines Enhance Freshness and Sustainability

-

Revolutionizing Efficiency: How Automated Packaging Machines Transform Your Production Line

-

Top 10 Custom Packaging Machines to Boost Your Business Efficiency in 2023

-

Top 5 Benefits of Using an Automated Packaging Machine for Your Business

-

Revolutionizing Supply Chains: The Future of Industrial Packaging Equipment Explained

-

Top 10 Packaging Automation Equipment for Streamlining Your Production Process