Top Tips for Choosing Packaging Equipment Systems for Your Business?

In the fast-evolving landscape of packaging equipment systems, making the right choice can significantly impact your business's efficiency and profitability. Industry expert John Smith, a veteran in packaging technology, emphasizes, “The right equipment can streamline processes and reduce costs.” This insight resonates deeply with companies looking to optimize their packaging lines.

Choosing packaging equipment systems involves careful consideration of various factors. Equipment must suit your production needs while ensuring flexibility for future growth. The balance between speed, quality, and cost is critical. Often, businesses overlook the importance of training personnel on new systems, which can lead to underutilization. This oversight may result in wasted opportunities and resources.

Moreover, what works for one company may not work for another. Equipment compatibility, space constraints, and even operational workflows play vital roles in the decision-making process. You might find yourself questioning whether your current systems meet industry standards. Reflecting on these aspects will lead to a more informed choice in your packaging equipment journey.

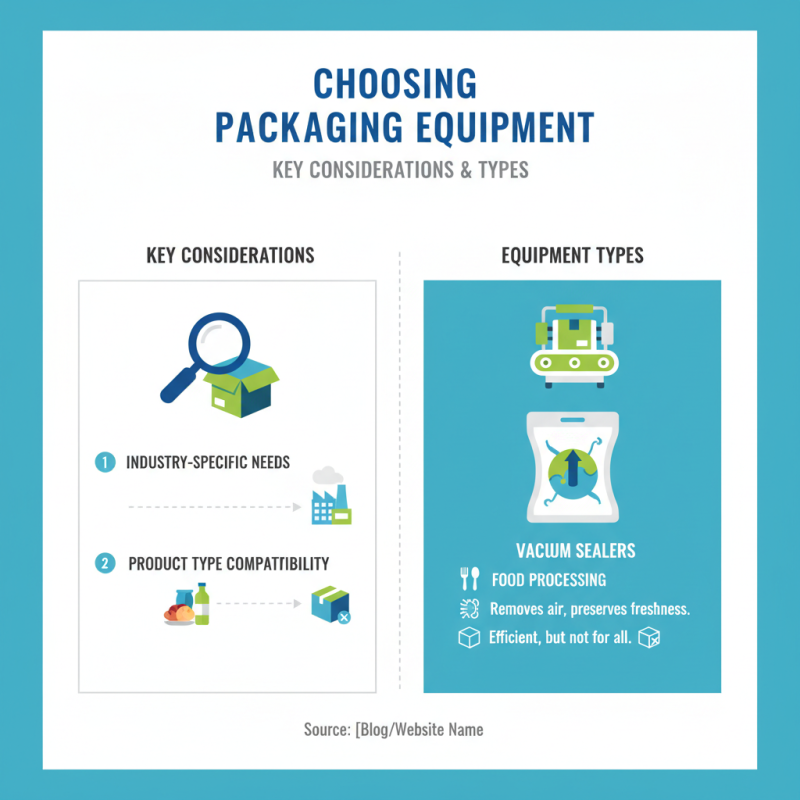

Understanding Your Business's Specific Packaging Needs

When selecting packaging equipment, understanding specific business needs is crucial. Many companies overlook this aspect. It can lead to costly mistakes. Each industry has unique challenges. For instance, food packaging must adhere to stringent safety regulations. According to a recent market report, 25% of businesses fail to analyze their packaging requirements adequately. This oversight often results in inefficiencies.

Identifying packaging volume is essential. A company handling 1,000 units per day must consider different equipment than one producing 10,000. Moreover, businesses should contemplate the type of materials used. The right equipment must handle specific materials, whether flexible plastics or rigid containers. The Packaging Machinery Manufacturers Institute states that 30% of companies report needing more flexibility in their equipment to adapt to changing demands.

It's also vital to assess budget constraints. Many organizations rush the purchasing process, leading to overspending. Being frugal is crucial, but it shouldn't sacrifice quality. Investing in the right system improves productivity. Businesses that fail to invest in optimal packaging systems may see increased labor costs. Packaging efficiency directly impacts the bottom line. An informed decision is critical for success in today's competitive market.

Top Tips for Choosing Packaging Equipment Systems for Your Business

| Requirement | Description | Importance Level | Example Equipment |

|---|---|---|---|

| Speed | How quickly the equipment can package products. | High | Automated packing machines |

| Flexibility | Capability to handle various package types. | Medium | Adjustable sealing machines |

| Cost | Initial investment and ongoing maintenance expenses. | High | Various packing systems |

| Ease of Use | User-friendly interfaces and controls. | Medium | Semi-automated machines |

| Maintenance Support | Availability of technical support and spare parts. | High | Service agreements |

| Compliance | Meeting industry standards and regulations. | High | Regulatory-compliant packaging systems |

Evaluating Total Cost of Ownership for Packaging Equipment

When evaluating packaging equipment, the total cost of ownership (TCO) plays a crucial role. TCO encompasses more than just the initial purchase price. It includes installation, maintenance, and operational costs over the equipment's lifespan. According to a recent report, operational costs can account for as much as 70% of TCO. This highlights the importance of considering long-term expenses rather than solely focusing on upfront investment.

Maintenance should not be overlooked. Frequent breakdowns can lead to production delays and increased costs. An analysis from the Packaging Machinery Manufacturers Institute indicates that businesses can save up to 30% on TCO by selecting equipment designed for easy maintenance. Continuous improvement in efficiency often results in lower energy consumption, further reducing operating costs.

Moreover, companies must consider the equipment's scalability. As businesses grow, their packaging needs may change. Investing in adaptable systems can mitigate costs associated with upgrading. A survey showed that 45% of manufacturers regret not prioritizing scalability when choosing packaging solutions. Reflecting on these aspects can lead to smarter investments for future needs.

Evaluating Total Cost of Ownership for Packaging Equipment

Exploring Types of Packaging Equipment and Their Applications

When choosing packaging equipment, understanding the types available is crucial. Different industries require different solutions. For example, food processing often uses vacuum sealers to preserve freshness. These machines remove air from packaging. They are efficient but might not be suitable for all products.

In contrast, filling machines are essential for liquid products. They ensure accurate doses and can handle various container types. However, they require regular maintenance to avoid operational glitches. It's vital to think about flexibility. Equipment that adapts to changing product lines can save money.

Consider the end-user experience as well. Packaging can enhance usability. A well-packaged product attracts more customers. But, striking a balance between functionality and aesthetic appeal is tricky. Explore all options before making a decision. Reflections on your packaging strategy can lead to better choices.

Assessing the Scalability and Flexibility of Equipment Systems

When evaluating packaging equipment systems, scalability and flexibility stand out as critical factors. Many businesses face fluctuating demand. According to a recent industry report, 72% of companies prioritize scalable systems that can adapt to changes. This flexibility allows businesses to scale operations up or down without incurring heavy costs.

Equipment that accommodates different package sizes is crucial. Systems should handle diverse packaging types, from pouches to boxes. About 65% of manufacturers report that equipment flexibility enhances their ability to respond to customer needs. However, not all equipment provides such versatility. Some systems may struggle with rapid changeovers, leading to production delays.

Investing in versatile equipment can yield long-term benefits. Yet, it can come with a higher initial cost. It’s important to analyze potential ROI against the challenges of inflexible systems. Businesses must weigh efficiency against adaptability and consider future market trends. Not all choices will lead to instant success, but thoughtful assessment can pave the way for growth.

Researching Supplier Reputation and Support Services in the Industry

Choosing the right packaging equipment involves careful consideration. One crucial factor is the supplier's reputation. Researching a potential supplier can significantly impact your business's success. Look for suppliers with a proven track record. Check online reviews and ask for references. This can provide insight into their reliability.

Support services are another key element. A good supplier should offer reliable customer support. Consider the availability of technical assistance. Having access to quick help during production issues is vital. It's not uncommon for problems to arise unexpectedly. The quality of support can make or break your operations.

Some businesses overlook the importance of training. Suppliers who provide training can help your team use equipment effectively. This enhances productivity and reduces errors. Remember, an initial lower price might lead to costly issues later. Reflect on these aspects to ensure long-term success in your packaging endeavors.

Related Posts

-

Revolutionizing the Food Industry How Food Packaging Machines Enhance Freshness and Sustainability

-

Revolutionizing Efficiency: How Automated Packaging Machines Transform Your Production Line

-

Revolutionizing Supply Chains: The Future of Industrial Packaging Equipment Explained

-

10 Best Custom Packaging Machines for Your Business Needs

-

Top 10 Custom Packaging Machines to Boost Your Business Efficiency in 2023

-

Top 10 Packaging Automation Equipment for Streamlining Your Production Process