Why Understanding Conveyor Parts is Essential for Efficient Operations?

Conveyor systems play a crucial role in various industries, from manufacturing to logistics. Understanding conveyor parts is essential for maintaining efficiency. According to a report by the Material Handling Industry of America, up to 70% of manufacturing operations depend on effective material handling systems, underscoring the importance of conveyor components.

Industry expert Dr. Robert Allen states, “Neglecting the functionality of conveyor parts can lead to significant downtime.” This insight highlights the need for a thorough understanding of these components. Efficient operations can only be achieved when each part, from rollers to belts, is in optimal condition. Frequent maintenance checks and proper knowledge of conveyor mechanics can prevent costly interruptions.

Despite advancements, many companies overlook the nuances of conveyor parts. They may assume all components are standard, which is not the case. Knowledge gaps often lead to unexpected failures and inefficiencies. The reliance on outdated systems can be detrimental. A comprehensive grasp of conveyor parts is essential for sustainable operational success.

The Importance of Conveyor System Design in Operational Efficiency

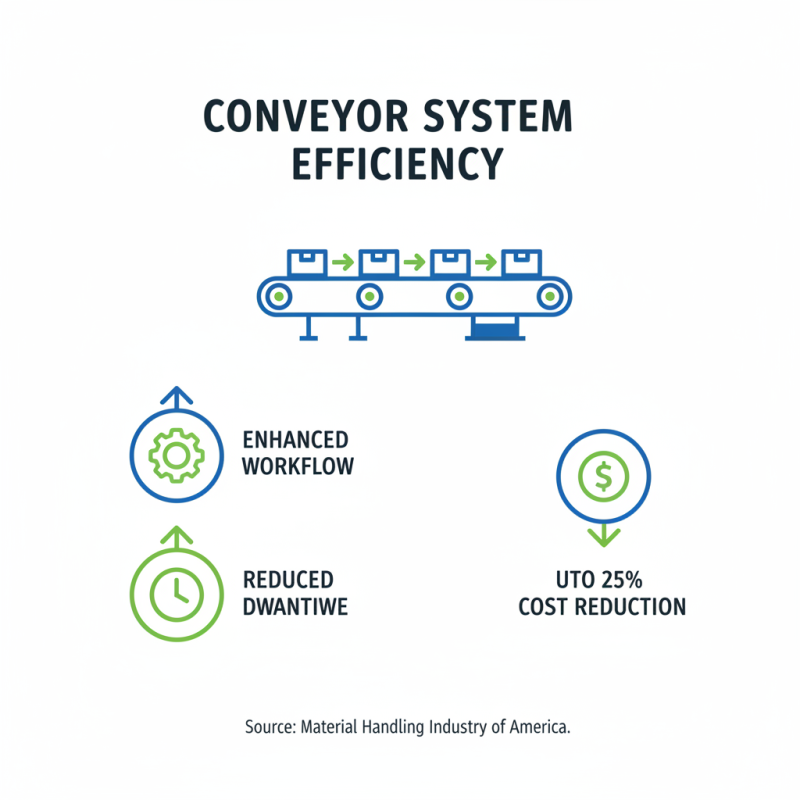

The design of conveyor systems plays a pivotal role in operational efficiency. When a conveyor system is well-designed, it can enhance workflow and reduce downtime. In fact, a report by the Material Handling Industry of America indicates that efficient material handling can reduce operational costs by up to 25%. This is crucial in environments where time equals money.

A poorly designed conveyor system can lead to excessive wear on parts and increased maintenance costs. Data from industry studies show that up to 30% of machinery failures can be traced back to inadequate design. Operators often overlook the placement and alignment of components. These oversights can result in bottlenecks that hinder productivity and slow down the entire production line.

Furthermore, an efficient design considers the specific needs of the operation. For instance, adapting the conveyor speed to match the workflow can drastically minimize delays. An intelligent layout can lead to fewer interruptions in production. However, not all operations realize the importance of tailored designs. Misalignment between component selection and actual needs leads to inefficiencies, ultimately affecting the bottom line. Improving design is necessary for enhancing performance.

Key Components of Conveyors and Their Functions Explained

Conveyor systems are vital in many industries. Understanding their key components helps ensure smooth operations. Each part plays a specific role in the overall function of the system.

The belt is the heart of the conveyor. It transports materials from one point to another. Rollers support the belt, reducing friction and wear. These parts must be maintained regularly to avoid breakdowns. If a roller fails, productivity can drop significantly. Then there are pulleys, which help control the belt’s movement. They redirect the belt, making transport efficient. If pulleys are misaligned, they can cause wear and tear.

Additionally, the motor powers the entire system. It provides the energy needed for movement. Motors need to be calibrated properly. An improperly calibrated motor can lead to uneven speeds and jams. Finally, control systems monitor and manage the operation. A glitch in these systems can disrupt the whole process. Understanding these components gives operators the insight necessary for efficient operations. However, regular training on these aspects becomes crucial for continuous improvement.

Common Issues in Conveyor Parts and Their Impact on Productivity

Conveyor systems are vital in modern operations. However, issues with conveyor parts can lead to significant productivity losses. For instance, misaligned rollers often cause uneven movement. This can slow down the entire operation. Regular maintenance is crucial to prevent these problems.

Wear and tear on belts is another common issue. When belts become frayed or stretched, efficiency drops dramatically. Employees may need to stop production for repairs. This time lost adds up quickly. Employees often feel frustrated when conveyors fail unexpectedly.

Additionally, sensors and motors can malfunction. A faulty sensor may not detect blockages, leading to jams. Jams can cause delays and headaches for the team. It's vital to monitor these parts closely. Ignoring these elements can lead to larger issues, resulting in costly downtime.

Strategies for Maintaining Conveyor Parts to Ensure Longevity

When it comes to the efficient operation of conveyors, maintenance is critical. Reports indicate that over 30% of conveyor failures can be traced back to improper maintenance practices. Regularly inspecting and servicing conveyor parts may seem like a hassle but is crucial for extending their lifespan. Operators should develop a routine that focuses on key components like belts, rollers, and drives.

Monitoring wear and tear is essential. For instance, a worn belt can decrease efficiency by up to 15%. This is not just a minor issue; it translates into significant operational costs. Keeping a close eye on tension and alignment can prevent future breakdowns. Wear indicators are also valuable tools; they can help identify when parts need replacement. While it’s easy to overlook small things, neglecting them can lead to bigger problems.

Investing in training for staff on proper maintenance is another strategy. A skilled team is more likely to notice potential issues early. Reports show that companies with trained maintenance personnel experience 20% fewer equipment failures. Though it may appear that cutting corners saves time, in reality, it can lead to longer downtimes and unexpected expenses. Prioritizing proactive measures will yield benefits in the long run.

Why Understanding Conveyor Parts is Essential for Efficient Operations?

| Part Name | Function | Maintenance Strategy | Expected Lifespan (Years) |

|---|---|---|---|

| Rollers | Support the conveyor belt and facilitate movement | Regular lubrication and cleaning | 5-10 |

| Belt | Transport materials between locations | Monitor for wear and tension adjustments | 3-7 |

| Drive Motor | Provides power to the conveyor system | Regular inspection and cleaning of housing | 5-15 |

| Idler Pulley | Supports the conveyor belt and guides its path | Check alignment and replace bearings as needed | 4-8 |

| Frame | Structure that supports the entire conveyor system | Inspect for corrosion and structural integrity | 10-20 |

Training Staff on Conveyor Parts for Improved Operational Workflow

Proper training on conveyor parts is crucial for improving operational workflow. Staff must understand how each component works. Knowledge gaps can lead to inefficiencies. When employees know the parts, they can troubleshoot issues quickly. For instance, if a belt slips, recognizing the cause becomes essential. This helps in preventing major downtime.

Hands-on training sessions can be beneficial. Staff members can practice identifying conveyor parts. Sometimes, training lacks the practical aspect. This can lead to confusion during actual operations. Therefore, including real scenarios in training is vital. If the team struggles with maintenance tasks, it indicates a need for better training.

Regular refreshers can also be useful. Conveyor systems evolve, and new parts may be introduced. Keeping staff informed about these changes is necessary. Reinforcing their knowledge ensures a smoother workflow. Ultimately, the goal is to create a team that can work efficiently. Addressing gaps in training enhances overall performance.

Related Posts

-

Top 10 Best Material Handling Equipment for Efficient Warehouse Operations

-

10 Best Conveyor Parts for Efficient Material Handling in Warehouses?

-

2026 How to Choose the Best Automatic Packaging Machines for Your Business?

-

What is Automated Packaging Equipment and Its Benefits?

-

2025 Top Filling Machine Innovations Enhancing Efficiency and Precision in Manufacturing

-

Top 10 Best Material Handling Carts for Efficient Warehouse Solutions